PolyJet 3D Printing Service

Prototypes, color concept models, and simulated overmold parts in days

Free shipping on all US orders

PolyJet 3D Printing

PolyJet printing is a 3D printing technology known for its customizable material properties, excellent surface finish, incredible precision and speed. Our PolyJet machines support the ability to simultaneously print multiple materials and simulate rubber materials of different durometers, multi-color 3D printing, transparent or translucent parts, and simulated overmolds.

- Rigid and rubber-like options

- Multi-material 3D printing

- Color and transparency matched prototypes

- Multi-color prints

- 3D prints in as little as a business day

- High resolution parts with a smooth finish

PolyJet Materials

| Material Name | Description | Shore Hardness | Elongation at Break (%) | Notched Impact Strength (J/m) | Data Sheets |

|---|---|---|---|---|---|

Material Name Photopolymer, Rigid | Description VeroUltra™ Black (RGD865), VeroUltra™ White (RGD825), VeroUltraClear Component (RGD820), VeroClear (RGD810) | Shore Hardness 83D - 86D | Elongation at Break (%) 7% - 12% | Notched Impact Strength (J/m) 19 - 25 J/M | Data Sheets |

Material Name Photopolymer, Rubber-like (Digital rubber) | Description Agilus30 + Vero | Shore Hardness 26-28A, 35-40A, 45-50A, 57-63A, 68-72A, 80-85A, 92-95A | Elongation at Break (%) 185% - 230% | Notched Impact Strength (J/m) N/A | Data Sheets |

Material Name Multi-Material, Mult-Color, Digital material | Description Combination of two or more PolyJet materials | Shore Hardness Varies | Elongation at Break (%) Varies | Notched Impact Strength (J/m) Varies | Data Sheets |

Digital material properties, such as Shore A rubber-like, may vary due to their microstructure and printed geometry.

Full Color 3D Printing With PolyJet

Xometry offers a full-color, high quality 3D printing service in addition to black, white, translucent, and grayscale utilizing the latest generation of PolyJet equipment from Stratasys. With over 600,000 available colors, Xometry can print color 3MF and other 3D formats. Have a Pantone, RAL, HEX, CMYK, or other color input? Choose "Custom" and write in the combination in your notes for a Xometry quote!

- VeroUltra™ Black (RGD865)

- VeroUltra™ White (RGD825)

- VeroCyan-V (RGD845)

- VeroMagenta-V (RGD852)

- VeroYellow-V (RGD838)

- VeroUltraClear Component (RGD820), VeroClear (RGD810)

- Agilus30 and rubber-like digital materials

- Digital ABS Plus, Ivory (upon request)

- Rigur, White (upon request)

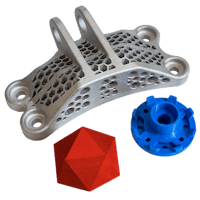

PolyJet Color 3D Printing Examples

Full Color 3D Printing Best Practices

PolyJet Finishes

Standard

Support material is removed, and parts are cleaned.

Additional Finishes

Xometry can provide additional processing and finishes to meet your needs. For example, you can request the print “Glossy,” a software setting that gives any upper-facing features a glossy appearance. Note that the Glossy setting will still make the underside and vertical edges matte and layer/streak lines may be prominent.

Ready to get started on your PolyJet quote?

Free shipping available for domestic 3D printing orders ; learn more!

Applications of PolyJet

Concept Models

The speed, efficiency, and range of build materials make PolyJet 3D perfect for concept models.

Rapid Prototyping

PolyJet 3D can be used to create quick-turn prototypes and test fit and finish.

Rapid Tooling

PolyJet 3D is ideal for making tools, jigs, and fixtures that can be used in production settings

Advantages of Polyjet

Efficiency

Eliminates the multi-stage processes of traditional manufacturing, such as tooling, milling, and creating molds.

Complex Geometry

Creates complex shapes with a high degree of precision that would otherwise be impossible to build via traditional manufacturing processes.

Rubber-like Flexibility

PolyJet 3D can build vastly different part geometries, unlike traditional processes that would necessitate a complete retooling of an assembly line to produce a different part.

Material Selection

Offers a vast material selection with a range of properties, as well as the ability to print multiple materials and simulate overmolds.

Rapid Turnaround

Because PolyJet 3D can create complex and multi-material parts in a single operation, significantly less build time is needed vs. traditional manufacturing. We can have parts to you in as fast as days.

Polyjet General Tolerances

| Description | Tolerance Notes |

|---|---|

Description General Tolerances | Tolerance Notes +/- 0.004” for the first inch is typical, plus +/- 0.002” for every inch thereafter. |

Description Build Area | Tolerance Notes Build area up to 19.3" x 15.4" x 7.9". |

Description Minimum Feature Size | Tolerance Notes 0.050" or greater for rigid. 0.060" or greater for rubber-like. |

Description Standard Layer Height | Tolerance Notes 0.0010" layers. |

This table depicts the general tolerances and guidelines for polyjet 3D printing. General tolerances apply before secondary finishing or post-processing unless otherwise specified. Please check out Xometry's Manufacturing Standards for more information on tolerances per process.

Need to Compare Printing Processes?

Our quick reference guides let you quickly compare different 3D printing processes!

Overview: What is PolyJet 3D Printing?

Polyjet 3D Printing Basics

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials.

How Polyjet Works

PolyJet 3D printed parts are built using photopolymer liquid resin. The printer places layers of photocurable resins onto a build tray in extremely fine layers. As the layers are placed, they are simultaneously cured via exposure to an ultraviolet (UV) light, solidifying them into solid material matching the programmed CAD file. This process repeats itself layer by layer until the entire part has been constructed. In the case of parts with complex geometries, support structures are added to the part to ensure a successful build and then manually removed during the finishing process.

Benefits of Polyjet 3D Printing

PolyJet technology is known for its customizable material properties and excellent surface finish, creating prototypes that are both detailed and smooth. Unlike traditional manufacturing processes, polyjet allows manufacturers to customize material properties, and supports various photopolymer options that can simulate a variety of different end-use materials. Combined with PolyJet’s high accuracy to CAD files and it’s overmold capabilities, this manufacturing process is a favorite for rapid prototyping.

Why Choose Xometry for PolyJet?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become Suppliers make it through our qualification process.