Nylon 3D Printing Service

Get instant online quotes on parts in nylon materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D certified.

About 3D Printing Nylon

3D printed nylon comes in many different forms, namely as a filament for FDM (fused deposition modeling) or as a powder for SLS (selective laser sintering) and MJF (HP Multi Jet Fusion) printing. 3D printing nylon creates parts with excellent properties but it’s important to understand that the type of 3D printing process will determine the final part capabilities. For example, FDM prints will have an anisotropic structure caused by the extruded layer lines. Even SLS-printed parts will have a level of anisotropy between layers. MJF parts tend to have isotropic properties, meaning the material will behave the same regardless of the direction of the load. However, with correct setups and part orientation, anisotropic effects can largely be negated and parts can benefit from the excellent properties of nylon.

Nylon is a high-performance engineering thermoplastic found in a wide range of industries. Its popular usage stems from its excellent abrasion resistance, high fatigue resistance, and high load-bearing capacity. Due to these properties, 3D printing in nylon is a great way to make lightweight industrial and medical implements that are just as capable as heavier metal ones.

3D Printed Nylon at a Glance

| Applications | Advantages | Disadvantages | Comparitive Cost | Layer Height | Build Envelope |

|---|---|---|---|---|---|

Applications

| Advantages

| Disadvantages

| Comparitive Cost $-$$ (Low-Medium) | Layer Height MJF: 0.0031" 0.0047" 0.007" - 0.013" | Build Envelope MJF: 15 x 11 x 15" 26" x 15" x 23" 24” x 36” x 36” |

Information based upon US-based services.

FDM Nylon Materials

We offer two distinct Nylon variants through our Fused Deposition Modeling (FDM) process, enabling you to select the ideal balance of performance and stability for demanding applications.

- Stratasys Nylon 12 is suitable for large-scale parts demanding reliability and resilience. This high-grade formulation delivers exceptional dimensional stability, ensuring mechanical properties are retained over extended use. It is inherently resistant to shocks and fatigue, making it the perfect material for components that must endure repeated load/unload cycles and significant operational vibration.

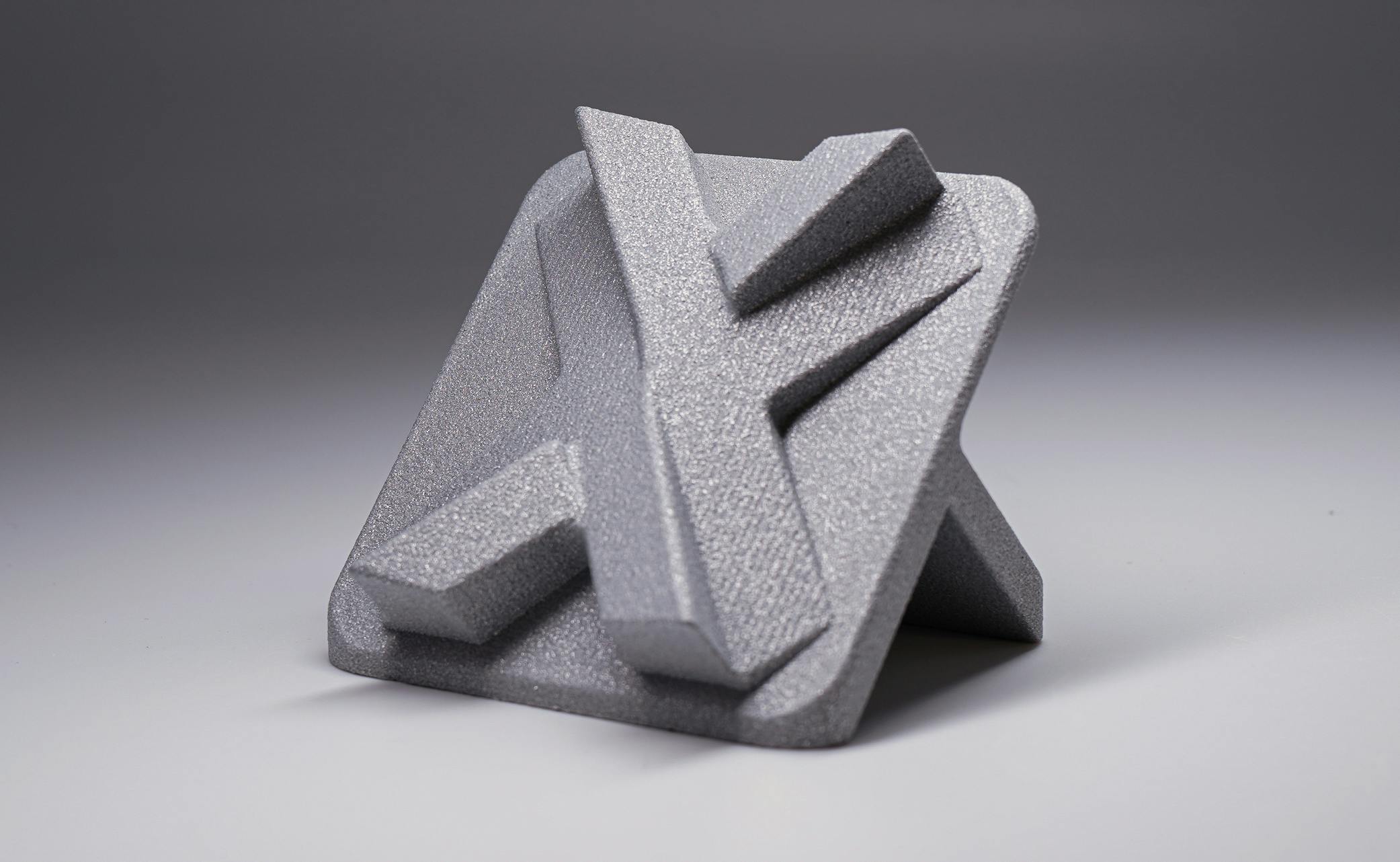

- Nylon 6 CF is an excellent choice when your design requires maximum strength and stiffness with minimal weight. This composite utilizes carbon fiber chop reinforcement to create incredibly strong, stiff, and lightweight parts. This versatile material has been popularized by industry leaders, including Markforged Onyx, as well as other carbon-filled filaments from Bambu Lab, Polymaker, and others. It's highly suited for printing light-weight fixtures, clamps, and structural components that require superior performance and heat resistance.

Note that FDM materials are inherently anisotropic. This means the orientation of the deposited layers strongly influences the resulting mechanical properties. Our experts carefully consider the build orientation to optimize strength and performance, providing you with reliable, high-integrity components.

FDM Nylon Material Properties

| Material Name | Tensile Strength (MPa) | Elongation at Break (XY, ZX %) | Heat Deflection Temperature (℃) @ 66psi | Impact Strength, Notched | Notes |

|---|---|---|---|---|---|

Material Name Nylon 6 CF | Tensile Strength (MPa) 48-102 | Elongation at Break (XY, ZX %) 5.8, 3.7 | Heat Deflection Temperature (℃) @ 66psi 186 | Impact Strength, Notched 13.4 kJ/m² per ISO 179 | Notes Carbon fiber-filled |

Material Name Nylon 12 | Tensile Strength (MPa) 41.8-49.3 | Elongation at Break (XY, ZX %) 6.5-30 | Heat Deflection Temperature (℃) @ 66psi 91.9-94.7 | Impact Strength, Notched 71-138 J/m per ASTM D256 | Notes Stratasys OEM brand |

Figures are indicative values based on supplier data and may vary depending on processing conditions. Provided for reference only.

Nylon 6 CF material properties and appearance may vary slightly due to a broad material and equipment allowance; data is for reference only. Nylon 12 properties achieved by running OEM materials and parameters on OEM Fortus equipment. See our FDM page for complete data sheets.

MJF Nylon Materials

Our Multi Jet Fusion (MJF) offering elevates Nylon's already excellent material properties, delivering production-ready parts with unmatched quality and consistency. MJF utilizes a unique fusing process that creates components with significantly greater isotropic properties and superior surface finish compared to FDM or FFF. Parts printed using MJF exhibit high detail and resolution, are inherently watertight, and are suitable for both rapid prototyping and end-use applications.

We offer multiple high-performance Nylon variants to meet your specific application needs:

- Nylon 12 is our "go-to" material for MJF, providing an excellent balance of mechanical strength, ductility, and chemical resistance. It is the ideal choice for general-purpose end-use parts, durable enclosures, and complex components requiring a superior surface finish.

- Nylon 11 is derived from renewable castor seeds, offering enhanced impact strength and ductility, making it more flexible and fracture-resistant. Use it for parts requiring higher flexibility, snap-fit features, and applications where fatigue resistance is critical.

- Nylon 12, Glass-filled (GF) is nylon 12 that has been reinforced with glass beads. This variant provides significantly increased stiffness, rigidity, and dimensional stability. It is the best option for jigs, fixtures, and structural components that require higher temperature resistance and greater load-bearing capabilities.

MJF Nylon Material Properties

| Material Name | Tensile Strength (MPa) | Elongation at Break (%) | Heat Deflection Temperature (℃) @ 66psi | Impact Strength, Notched | Notes |

|---|---|---|---|---|---|

Material Name Nylon 11 | Tensile Strength (MPa) 52 | Elongation at Break (%) 55, 40 (XY, ZX) | Heat Deflection Temperature (℃) @ 66psi 185 | Impact Strength, Notched 6, 5 kJ/m² (XY, ZX) | Notes Flexible and fracture-resistant |

Material Name Nylon 12 | Tensile Strength (MPa) 48 | Elongation at Break (%) 20, 15 (XY, Z) | Heat Deflection Temperature (℃) @ 66psi 175 | Impact Strength, Notched 3.5 kJ/m² | Notes Balanced properties, general-purpose |

Material Name Nylon 12, Glass-filled (GF) | Tensile Strength (MPa) 30 | Elongation at Break (%) 10 | Heat Deflection Temperature (℃) @ 66psi 174 | Impact Strength, Notched 3 kJ/m² | Notes 40% glass bead-filled, increased stiffness |

Figures are indicative values based on US-supplier data and may vary depending on processing conditions. Provided for reference only. See our MJF page for full data sheets.

SLS Nylon Materials

Our Selective Laser Sintering (SLS) process allows for enhanced design and material customization for nylon components. SLS produces parts with exceptional resolution and detail, providing high-dimensional accuracy and reliable mechanical properties. A key benefit of SLS nylon is the availability of naturally white materials that can be easily dyed a variety of colors, allowing for visual customization without sacrificing performance. Furthermore, SLS boasts a broad array of filled and specialty materials, enabling you to select the exact properties needed for demanding applications, from rigidity and thermal stability to flame resistance.

We offer both standard and advanced nylon formulations through our SLS process:

- Nylon 11 EX is an excellent choice for parts requiring high flexibility and impact resistance. Derived from renewable sources, this material is ideal for thin-walled components, living hinges, and applications that require superior ductility and fatigue performance.

- Nylon 12 is the industry-standard SLS polymer, known for its balanced mechanical strength, excellent chemical resistance, and high rigidity. It serves a wide range of applications for durable, general-purpose functional prototypes and end-use parts.

- Specialty nylon 12 materials are available for enhanced performance. We offer advanced composite powders infused with various fillers, including Glass-Filled (GF), Carbon-Filled (CF), and Aluminum-Filled (AF) options, which provide increased stiffness and thermal resistance. Additionally, we offer specialized variants such as Mineral-Filled (HST) for enhanced stability and Flame Retardant (FR) for safety compliance.

SLS Nylon Material Properties

| Material Name | Tensile Strength (MPa) | Elongation at Break (%) | Heat Deflection Temperature (℃) @ 66psi | Impact Strength, Notched | Notes |

|---|---|---|---|---|---|

Material Name Nylon 11 EX | Tensile Strength (MPa) 45 | Elongation at Break (%) 45 | Heat Deflection Temperature (℃) @ 66psi 188 | Impact Strength, Notched No Break | Notes Flexible and impact-resistant |

Material Name Nylon 12 | Tensile Strength (MPa) 48-42 (XY, Z) | Elongation at Break (%) 4-18 | Heat Deflection Temperature (℃) @ 66psi 157-146 (X, Z) | Impact Strength, Notched 4.8 kJ/m² | Notes Balanced properties, general-purpose |

Material Name Nylon 12, Glass-filled (GF) | Tensile Strength (MPa) 51-47 (XY, Z) | Elongation at Break (%) 9 | Heat Deflection Temperature (℃) @ 66psi 157 | Impact Strength, Notched 5.4 kJ/m² | Notes 40% glass bead-filled, increased stiffness |

Material Name Nylon 12, AF (PA 605-A) | Tensile Strength (MPa) 43-37 (XY, Z) | Elongation at Break (%) 3 | Heat Deflection Temperature (℃) @ 66psi 180 | Impact Strength, Notched 58.7 J/m | Notes 40% Aluminum-filled |

Material Name Nylon 12, CF (PA 602-CF) | Tensile Strength (MPa) 66 | Elongation at Break (%) 5 | Heat Deflection Temperature (℃) @ 66psi 175 | Impact Strength, Notched 54 J/m | Notes 23% carbon-fiber-filled, resistant to warping at high heat |

Material Name Nylon 12 HST (PA 620-MF) | Tensile Strength (MPa) 51-34 (XY, Z) | Elongation at Break (%) 3-5 | Heat Deflection Temperature (℃) @ 66psi 184 | Impact Strength, Notched N/A | Notes 25% mineral-filled, increased stiffness for higher heat applications |

Material Name Nylon 12 FR (PA 606-FR) | Tensile Strength (MPa) 48 | Elongation at Break (%) 24 | Heat Deflection Temperature (℃) @ 66psi 180 | Impact Strength, Notched 32 J/m | Notes Flame retardant (FAR 25.853 60 second) |

Figures are indicative values based on US-supplier data and may vary depending on processing conditions. Provided for reference only. See our SLS page for full data sheets.

Cost-saving Design Tips

DFM: Each type of 3D printing technology requires special considerations during the design phase. For example, with FDM parts you should be mindful of support structures and consider the layer orientation that will generate maximum strength. SLS and MJF parts need drain holes to remove unused powder from internal cavities and should not have overly thick walls. Design-for-manufacturability (DFM) principles need to be applied from the start.

Choose the right plastic and process: Each of the above plastics and process combinations is better suited to certain applications. If the goal is to produce a temporary tooling jig, then Nylon 12 in FDM may be suitable. However, if a visual prototype is required, then SLS or MJF may better suit your needs. Use specialty or filled materials when the application demands it; otherwise, you may be paying more for characteristics you don't need.

Finishes

Xometry offers a wide range of surface finishes for nylon 3D prints, some of which are listed below. Visit our finishes page to learn about our other finishing options.

Standard: Available for all technologies and materials. Printing supports are removed from the part, but no additional work is done to the finish. Note that SLS and MJF parts have much better off-the-machine finishes than FDM and do not require the removal of support structures.

Color Dyeing: Parts are submerged in a dye solution that penetrates roughly ~0.010” into the surface, altering the surface’s color. Coloration may vary slightly from batch to batch. Available for SLS and MJF nylon parts.

Vapor Smoothing: Vapor smoothing creates a uniform, sealed surface with a semi-gloss appearance. It can be combined with our color dyeing option. Available for SLS and MJF nylon 12 parts.

Nickel plating: This surface treatment is not for cosmetic applications, as it creates a rough nickel finish. However, it adds additional durability, stiffness, and wear resistance. This finish is only available for SLS nylon parts.

Drone part 3D printed in Nylon 6 CF via FDM.

Need Parts 3D Printed in Nylon?

Get instant pricing and lead times today!