3D printing and additive manufacturing might initially seem to mean the same thing, but a deeper look uncovers important differences in their uses and operating principles. The term 3D printing has gained popularity recently and refers to a process for building three-dimensional objects by layering material.

Contrarily, additive manufacturing uses a wider range of methods to create complex structures, going beyond the usual use of metals and polymers. Their objectives and commercial ramifications are the areas in which they diverge the most. Hobbyists and designers often use 3D printing because it is accessible and affordable. In contrast, additive manufacturing, with its versatility in materials and precision, is the backbone of diverse industries, from aerospace to healthcare. This article will investigate the distinct characteristics that differentiate these two processes.

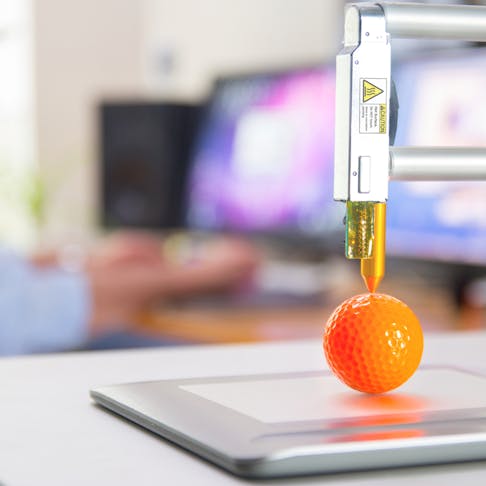

What Is 3D Printing?

3D printing is a revolutionary technology that fabricates three-dimensional items by creating them layer by layer.

3D printing uses a variety of materials such as: plastics, metals, and ceramics. Utilizing computer-aided design (CAD) software, this technique uses digital designs. Its importance comes from its ability to quickly prototype complex designs and create customized, intricate components, easing the limitations of traditional production. 3D printing is a tool for creativity and efficiency in product development, manufacturing, and even the creation of medical implants. It has uses in a wide range of industries, including: aerospace, healthcare, automotive, and the arts. For more information, see our guide on 3D Printer Technology.

What Are the Advantages of 3D Printing?

The benefits of 3D printing include:

- Enables the creation of intricate and customized designs that traditional methods struggle to replicate.

- Speeds up product development by allowing quick iteration and testing of prototypes, reducing time-to-market. Reduced material waste and tooling costs make it economically viable for small-batch or one-off production.

- It's becoming more accessible to individuals and smaller businesses, democratizing manufacturing capabilities. Customized products and medical implants are feasible and tailored to specific needs.

What Are Examples of 3D Printing Uses?

There are many examples of applications for 3D printing. In the medical experimental field, 3D printing is used to create organs, tissues, and bones for transplantation. While that journey continues, personalized prostheses and titanium skull sections are already available as potential medical solutions. Clearly, 3D printing holds the promise of revolutionizing healthcare by providing patient-specific solutions. 3D printing has been employed to construct houses and structures—even two-story houses from concrete. This innovation has the potential to revolutionize the construction industry, enabling rapid, cost-effective building in various architectural designs. Industries like automotive and aerospace utilize 3D printing to produce replacement parts, prototype new products, and improve production efficiency. It's also used to create customized bicycle parts, shoes, and musical instruments, offering new avenues for innovation and customization. In the culinary world, 3D printing is breaking barriers. Edible foods like chocolate, ice cream, and marzipan can be 3D printed, offering chefs and food enthusiasts new possibilities for creative and visually appealing dishes.

3D printed translucent part.

What Is Additive Manufacturing?

Additive manufacturing (AM) is defined as the construction of items through the addition of material, which may or may not follow a layer-by-layer methodology. In contrast to subtractive manufacturing, which entails material removal, additive manufacturing creates objects piece by piece. Computer-aided design (CAD) software and specialized equipment are required. This technology offers a special edge in assessing elements like ergonomics, size, and precision of parts and prototypes. It has many uses, especially in fields that value the synergy of timely and high-quality output, such as the industrial and professional domains and specialized industries. With real-time design alterations possible during the prototyping and verification phases, additive manufacturing excels at offering precision, reliability, and flexibility.

What Are the Advantages of Additive Manufacturing?

The following are some benefits of additive manufacturing:

- Minimizes material waste by building objects layer by layer or simply by the addition of material. It also conserves energy by consolidating parts.

- The cost of entering additive manufacturing is decreasing steadily, with affordable industrial-quality printers and materials, making it accessible to a wide range of industries.

- Additive manufacturing offers speed and cost-efficiency for small-batch production runs, making it ideal for producing limited quantities of parts. Facilitates cost-effective rapid prototyping. It saves both time and money compared to CNC milling setups, which can be expensive.

- Eliminates the need for extensive on-hand inventory by allowing parts to be stored digitally and printed on-demand, saving warehouse space and costs.

What Are Examples of Additive Manufacturing?

Additive manufacturing is used to produce eyeglass frames tailored to individual needs. Monoqool, a Danish start-up, utilizes 3D printing—merely one type of additive manufacturing technology—to create innovative and stylish eyeglass frames made from a single piece of plastic. Custom medical implants, made from various materials, are produced using AM technologies like stereolithography (SLA) and selective laser sintering (SLS). These implants are used in orthopedic, craniofacial, and spinal surgeries. Dental implants, custom-made to fit each patient's mouth, are produced using additive manufacturing. Companies like Align Technology and Straumann use AM to create dental implants and clear aligners. AM is used to manufacture engine parts for aerospace, automotive, and power generation applications.

What Is the Difference Between 3D Printing and Additive Manufacturing in Terms of Creation Processes?

3D printing typically refers to consumer-grade, desktop-sized machines that create objects by depositing material layer by layer. It's commonly used for rapid prototyping and hobbyist projects.

Additive manufacturing, on the other hand, encompasses a broader range of techniques, including industrial-scale processes like laser sintering and electron beam melting. It's used for manufacturing functional, end-use parts in industries like aerospace and healthcare.

What Is the Difference Between 3D Printing and Additive Manufacturing in Terms of Types?

SLA and FDM (fused deposition modeling) are subsets of additive manufacturing and are largely used in 3D printing. Although 3D printing is affordable and easily accessible to consumers, there are restrictions on its accuracy and available materials. Precision and material variety are strengths of additive manufacturing. However, it can be expensive and complex for industrial applications, requiring specialized tools and knowledge. The selection is based on the requirements of the particular project. For more information, see our guide on Types of 3D Printing.

What Is the Difference Between 3D Printing and Additive Manufacturing in Terms of CAD Software?

Both additive manufacturing and 3D printing rely heavily on CAD (Computer-Aided Design) software. They use CAD tools to build complex 3D models that direct the manufacturing process. Similar benefits and drawbacks apply to both. Precision and customization are possible using CAD software, but there is a learning curve and a time commitment involved in becoming proficient. In essence, CAD software facilitates exact and individualized designs, which is essential to both 3D printing and additive manufacturing.

What Is the Difference Between 3D Printing and Additive Manufacturing in Terms of Materials Used?

Additive manufacturing encompasses a broader spectrum, including metals, ceramics, and specialized alloys, ideal for high-precision industrial projects. While 3D printing may have limited material options, additive manufacturing offers versatility but can be complex and costly for consumer use. The material choice hinges on project-specific needs and scale. For more information, see our guide on Materials Used in 3D Printing.

What Is the Difference Between 3D Printing and Additive Manufacturing in Terms of Applications?

Customers often make use of 3D printing for small-scale requirements like prototyping and specialized goods. Contrarily, due to its accuracy and material flexibility, additive manufacturing excels in large-scale industrial and commercial applications. It is common in the automotive, medical, and aerospace industries. While additive manufacturing can be complex and expensive for consumers, depending on the scale, 3D printing has the advantages of accessibility and cost-effectiveness.

What Is the Difference Between 3D Printing and Additive Manufacturing in Terms of Machine?

In general, 3D printing involves inexpensive, consumer-grade devices ideal for small-scale applications and hobbies. Contrarily, industrial-grade machines that are bigger, more intricate, and more precise are a feature of additive manufacturing, which supports a wide range of commercial and industrial applications. The key point here is that while 3D printing is still affordable and appropriate for amateurs and smaller projects, additive manufacturing is customized to industrial demands. To learn more, see our article on Inexpensive 3D Printers.

What Is the Difference Between 3D Printing and Additive Manufacturing in Terms of Cost?

Hobbyist 3D printers, ranging from $400 to $1,000, offer affordability to enthusiasts but require significant setup and fine-tuning. Professional-grade 3D printers range in price from $3,000 to $10,000 and strike a balance between cost and dependability. These are emerging as crucial tools for engineers and designers in the field of additive manufacturing. Industrial 3D printers costing $10,000 and more target specialist materials and applications and necessitate a large investment for certain manufacturing needs.

What Is the Difference Between 3D Printing and Additive Manufacturing in Terms of Quality?

When weighing up 3D printing vs additive manufacturing in terms of quality, it becomes evident that additive manufacturing, as a broader category, often offers superior quality. 3D printing, often of prototypes, has lower quality, limited precision, and strength. In contrast, AM, comprising industrial processes, delivers superior quality suitable for critical applications in aerospace and healthcare. Yet, AM is more complex, costly, and relies on specialized equipment. It offers a broader material selection, enhancing flexibility but requiring careful material choice.

Is 3D Printing Analogous to Additive Manufacturing?

Yes, 3D printing is analogous to additive manufacturing to some extent. The term "3D printing" is commonly used as a broad, inclusive way to describe various additive manufacturing processes. However, it's essential to note that 3D printing is more specific, focusing primarily on transforming digital CAD files into physical 3D objects layer by layer. Additive manufacturing, on the other hand, encompasses a wider range of techniques beyond just 3D printing.

Is 3D Printing a Subset of Additive Manufacturing?

Yes, 3D printing is a subset of additive manufacturing. 3D printing is one of the many processes included in additive manufacturing that may be used to construct products. Objects are created through the layer-by-layer application of material from a digital design. While other additive manufacturing processes, including direct metal laser melting, use various technologies and materials, they all share the same basic idea of additive production.

Summary

This article presented 3D printing vs. additive manufacturing, explained each of them, and discussed their various differences. To learn more about 3D printing and additive manufacturing, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.