ABS injection molding is a common manufacturing process that involves injecting molten plastic into a mold cavity under high pressure and temperature. This technique is used in the automotive, consumer products, and construction industries for producing various components and products. We’ll cover the definition, uses, process, and techniques involved with ABS injection molding below, but for a brief recap, take a look at our short video below:

What is ABS Injection Molding?

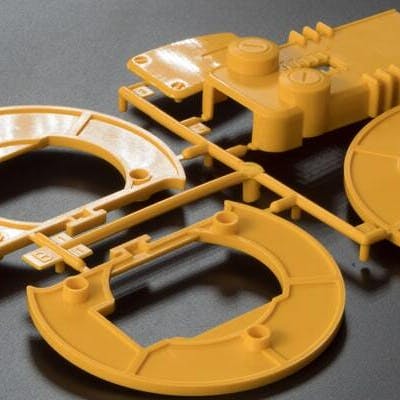

ABS (acrylonitrile butadiene styrene) injection molding is a standard way to make ABS plastic products. ABS is a strong and lightweight thermoplastic polymer that’s easy to work with. The process involves adding molten ABS into a mold cavity and then removing it after it cools. It’s a fast and useful method that’s used to craft ABS products at an affordable cost. It’s a popular go-to for household appliances, tools, and medical devices. It’s used to make Lego bricks, computer keyboard keys, power tool housings, and power outlet fittings, and in the automotive sector, is used for dashboards, seat belt parts, door trim, and bumpers. Below is a picture of a part made with ABS injection molding

Almost any thermoplastic can work for injection molding. They can be filled with reinforcing additives like glass or carbon fiber fillers. You can also inject metals if it’s combined with a plastic filler, allowing the metal powder to flow through the mold. That said, additional sintering is needed for metal injection molding. The ABS injection molding process is the same as with most other thermoplastics. Resin pellets get fed into a hopper, where they’re melted and injected into a mold using high pressure. Once it’s cooled and re-solidified, it’s removed from the mold. The simple and efficient process makes it perfect for high-volume production, and it creates very little waste, too.

The intricacy of the parts you can make is only limited by a set of well-established DFM (design for manufacturing) guidelines that are created specifically for injection molding. It can make multi-featured, complex parts with metal inserts or overmolded soft-grip handholds, and you can easily add a range of colors (think: Lego bricks). This is all without the need for much human intervention, something that keeps labor costs to a minimum and also makes the parts more affordable for customers (obviously the cost and time required increase with the complexity of the part). ABS is easy to shape, recyclable, resistant to chemicals and heat, and has a low melting temperature. It won’t allow dirt to get in, but it doesn’t do too well in UV light and prolonged outdoor exposure. To give it a little more power against the elements, it can be painted or electroplated with metal.

ABS’s viscosity increases when heated past its plasticizing temperature (unlike most other amorphous plastics), so it needs to be kept at or below that temperature for good results, especially when it comes to molding thin-walled components. Aside from an increase in viscosity, higher temperatures can chemically degrade ABS, if kept well above the plasticizing temperature. The plastic could also warp if it cools unevenly, but this can be prevented by using a mold with evenly spaced cooling channels. It could also shrink unevenly during cooling, creating sunken areas on the surface, if the temperature is too high or the injection pressure isn’t sufficient. Again, these marks (known as sink marks) can be avoided if you use a mold with a high gate pressure.

In relation to the actual injection molding process, there’s a high initial investment for the machinery (which is why it’s better suited for high-volume production), and a minimum part quantity is needed to break even on mold costs. In addition, some may find the DFM’s rules a little limiting when it comes to more creative designs. These standards were created to improve part quality and consistency, as well as cover things like wall thickness limits, the location of reinforcing features (like ribs), and the best hole location/size.

Why Is ABS Used in Injection Molding?

ABS is widely used in injection molding because of its desirable properties. These include high strength, low melting temperature, recyclability, and good resistance to chemicals and heat. It is also relatively easy to process and can be molded into a variety of shapes and sizes. As a result, ABS is an ideal choice for applications in which strength and durability are required, such as: automobile parts, household appliances, tools, and medical devices. Overall, ABS is a versatile and popular choice for injection molding.

What Are the Applications of ABS Injection Molding?

ABS is used in many different industries. Some common industries and their relevant applications are listed below.

- Consumer Products: ABS is widely used in the consumer industry. Typical products include LegoⓇ bricks and computer keyboard keys. ABS produces a smooth, shiny surface that is impervious to dirt impregnation. ABS will react well to the inclusion of pigments and can be easily painted or even electroplated if desired.

- Construction Industry: ABS is used for housings on many power tools due to its durability. Power outlet fittings are also often manufactured from ABS.

- Automotive industry: ABS is typically used for parts such as: dashboards, seat belt parts, door trim, and bumpers due to its low weight, durability, and strength.

What Is the ABS Injection Molding Process?

The ABS injection molding process is the same as the process involved with injection molding in most other thermoplastics. The ABS injection molding process begins with pellets of ABS resin being fed into a hopper. The pellets are then melted and injected into a mold under high pressure. Once the molten ABS has cooled and solidified, the part is ejected from the mold and the process is repeated. The ABS injection molding process is relatively simple and efficient, making it ideal for high-volume production runs. ABS also has good dimensional stability and can be easily machined or drilled after molding.

What Are the ABS Injection Molding Techniques?

Depending on what you’re trying to make with this method, the technique will be different. Here are some examples:

- Thin wall: Due to the aforementioned high viscosity, pressure has to be increased for thin-walled parts, and the molds have to be designed to handle the added pressure.

- Large and hollow: Creating large, thin, or hollow parts is generally difficult, but using water- or gas-assisted injection molding can help. This technique presses the molten plastic against the sides of the mold to create even thickness and smoothness.

- Thick wall: Standard techniques can create sink marks on thick-walled parts. One way to handle this is by using compression injection molding. This adds a specific amount of molten plastic into a mold to create the final part. It also reduces internal stresses. Sink marks can also be managed with thinner mold walls or higher thermal capacity in the mold.

- Multi-material: If you need components made from various materials, consider techniques like insert molding or overmolding. For example, cordless drills have their handles overmolded onto ABS to improve the tool’s grip.

What Are the Advantages of ABS Injection Molding?

The advantages of ABS injection molding are:

1. High Productivity - Efficiency

Injection molding is a highly efficient and productive manufacturing technology and is the preferred method of manufacturing ABS parts. The process creates limited waste and can produce large volumes of parts with limited human interaction.

2. Design of Complex Parts

Injection molding can produce multi-featured, complex components that can include metal inserts or overmolded soft-grip handholds. The complexity of the parts is only limited by a set of well-established design for manufacturing (DFM) guidelines developed specifically for injection molding.

3. Increased Strength

ABS is a strong, lightweight thermoplastic that is widely used in a number of industries due to these properties. As such, injection molding in ABS is ideal for applications that require increased durability and overall mechanical strength.

4. Flexibility of Color and Material

ABS is easily colored with a wide range of colors; this is evident with LegoⓇ bricks which are made from ABS. It must be noted however that ABS has poor weathering resistance and can be degraded by UV light and prolonged outdoor exposure. Fortunately, ABS can be painted and even electroplated with metal to improve its environmental resistance.

5. Decreased Waste

Injection molding is inherently low-wastage production technology due to the large production volumes that injection molding was designed for. When millions of parts are made per year, any amount of wastage adds up to a significant cost over time. The only wastage is the material in the sprue, runners, and the flashing between mold halves.

6. Low Cost of Labor

Due to the highly automated nature of injection molding, very limited human intervention is required. Reduced human intervention results in reduced labor costs. This reduced labor cost ultimately results in a low cost per part.

What Are the Disadvantages of ABS Injection Molding?

The disadvantages of ABS injection molding are listed below:

1. High Tooling Costs and Extended Lead Times for Setup

Injection molding requires the design and manufacture of molds whose cost and manufacturing time increase with part complexity. As such, the initial investment in injection molding is high, and the cost must be weighed against the expected production volumes. Lower production volumes may not be economically viable.

2. Partial Design Limitations

Injection molded part designs are limited by a set of rules that were painstakingly developed to improve injection molded part quality and consistency. These rules define wall thickness limitations, the location of reinforcing features like ribs, and the optimal hole location and size. As such, designs must be made to follow these rules to ensure optimal results. In some cases, these rules can make certain designs unfeasible.

3. Costly Small-Run Parts Are a Possibility

Due to the high initial investment cost when injection molding, there is a minimum part quantity required to break even on the costs expended on the design and manufacture of the mold. This break-even point is also dependent on the intended sale price of the final product. If the sale price is high—due to the part being used for a specialized application—it may be possible to have small-run manufacturing. However, low-cost parts require high volumes in the 10s of thousands to be cost-effective.

What Are the Common Problems in ABS Injection Molding?

While ABS is one of the most widely used plastics for injection molding, there are still problems that present themselves when using this material, as listed below:

- Viscosity: Unlike most other amorphous plastics, the viscosity of ABS increases when heated past its plasticizing temperature. This increase in viscosity means that the melt temperature of ABS must be kept at or below this temperature for optimal results as increased viscosity will make it more difficult to mold thin-walled components.

- Thermal Degradation: Apart from an unfavorable increase in viscosity with increased temperature, ABS tends to chemically degrade if kept at temperatures far above its plasticizing temperature.

- Warping: Warping occurs when ABS plastic cools unevenly, resulting in distortion. Warping can be prevented by using a mold with evenly spaced cooling channels. Ejecting parts from the mold before they have had a chance to cool sufficiently can also result in warping.

- Sink Marks: Sink marks can occur when the ABS plastic shrinks unevenly during cooling, causing sunken areas on the surface of the part. Other potential causes can be insufficient injection pressure or excessive temperature. Sink marks can be prevented by using a mold with high gate pressure, designing a part with uniform outer walls, and limiting internal strengthening ribs to around 50% of the thickness of the outer walls.

What Material Is Used for Injection Molding?

Injection molding can be used with almost any thermoplastic. Thermoplastics can be filled with reinforcing additives like glass or carbon fiber fillers. Metals can also be injected if combined with a plastic filler material to allow the metal powder to flow through the mold. However, additional sintering is needed for metal injection molding.

How Xometry Can Help

Xometry provides a wide range of manufacturing capabilities, including CNC machining, 3D printing, injection molding, laser cutting, and sheet metal fabrication. Get your instant quote today.

Copyright and Trademark Notice

- LegoⓇ is a registered trademark for LEGO JURIS A/S CORPORATION DENMARK KOLDINGVEJ.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.