CNC (Computer Numerical Control) machining refers to manufacturing parts by removing material with a cutting tool under automated control rather than manual operation by a machinist. In CNC machining, either the cutting tool is held stationary while the workpiece moves, or the tool itself is rotated and moved into a stationary workpiece. CNC machining is often performed on metals but can also be employed with plastics and composites.

CNC machining has revolutionized manufacturing since its introduction in 1952 with the Cincinnati Milacron Hydrotel. Since then, advanced robotics systems have been incorporated into the machines to dramatically improve productivity and ultimately reduce the labor requirements for the manufacturer of components.

This article will cover the history of CNC machining, how CNC machining works, and some of the more common use cases for this process.

What Is CNC Machining?

CNC machining refers to a type of subtractive manufacturing that is designed for manufacturing a part automatically by either advancing a spinning cutting tool mounted on a spindle into the work material (CNC mill) or by mounting the raw stock onto a spindle and rotating it against a stationary cutting tool (CNC lathe). The main function of a spindle in a CNC machine is to provide rotational motion to allow for the cutting of material.

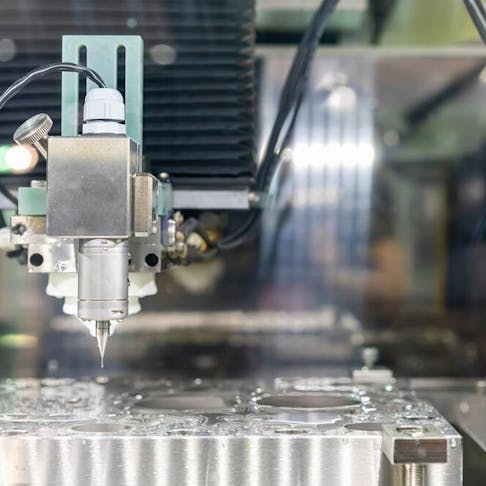

An operator sets up the part by generating a list of instructions—detailing tool movements, speeds, and cutting depths—that guide the machining process. While early CNC programs were handwritten, today’s machines rely on advanced software to generate and execute the required code. Once the program instructions have been entered into the machine controller, the operator places the raw material into its starting position and initiates the machining sequence. The CNC machine then performs the planned manufacturing process steps. CNC machines have varying degrees of automation. Fully automatic machines can even load raw material and unload finished parts by means of a robot arm, as shown in Figure 1 below:

When Was CNC Machining Invented?

The first CNC machine prototype was developed in 1952 by a team of researchers at MIT (Massachusetts Institute of Technology). This advancement followed the development of the first NC (Numerical Control) machine in 1949. CNC machines were patented in 1958.

Who Invented CNC Machining?

John T. Parsons is credited with inventing and building the first NC machine. The NC machine was designed to operate directly off a set of punch cards that tell the machine where to move. This concept laid the groundwork for the further development of the CNC machine. A team of researchers working at MIT, led by J.F. Reintjes, developed the first prototype CNC milling machine. Richard Kregg later collaborated with MIT to develop the Cincinnati Milacron Hydrotel, recognized as one of the first commercially available CNC machines. Cincinnati Milacron became one of the first manufacturers of CNC machines.

Where Was CNC Machining Created?

The first CNC machine prototype was developed in the USA at MIT. The first commercial CNC machine was developed in Cincinnati in collaboration with MIT.

Why Was CNC Machining Created?

CNC machining was developed to enable the production of complex shapes that traditional manual milling techniques could not achieve. It allows for the machining of mathematically developed, non-linear curves that would be difficult or impossible to produce manually.

What Is the Main Objective of CNC Machining?

The main objective of CNC machining is to produce precise, repeatable parts with minimal human intervention, thereby reducing cost per part while maintaining high quality.

What Existed Before the CNC Machine?

NC machines were developed before CNC machines. NC machines were programmed with punch cards and later by magnetic tape. Ultimately, no computer was used—the process is similar to that of old automatic pianos which used punch card rolls to play music. These instructions were read by the machine, which then manufactured the part.

What Was the Earliest Use of CNC Machining?

The earliest application of CNC machining was the production of helicopter blades using mathematically developed aerofoil shapes in 1949.

What Industry Uses CNC Machining?

Almost every industry makes use of CNC machining in some form. However, the primary users of CNC machining are listed below:

- Automotive: Combustion engines require exact tolerances to operate efficiently. For example, cylinder heads and gearboxes are typically manufactured using CNC machining.

- Aerospace: The aerospace industry uses CNC machining extensively due to the requirements for repeatable and precise machining. Some typical applications include turbine blades, rocket combustion chambers, and hydraulic manifolds.

- Medical: The medical industry often requires components with complex geometries and small tolerances to fit and align with human limbs and joints. This is an ideal use case for CNC machining; typical components include hip joints, surgical tools, and prosthetic limbs.

- Electronics: Electronic components require extreme precision. For that reason, CNC machining is used extensively in this industry. Typical applications include consumer product enclosures to protect sensitive electronics, heat sinks, and wafer chucks and carriers for semiconductor components.

When Did CNC Machining Become Popular?

CNC machining began gaining popularity in the late 1960s. In 1976, the first CAD (Computer Aided Design) systems became available to create 3D models for generating machine G-code, easing access to CNC technology. By 1989, CNC machining had become the standard for large-volume manufacturing and production.

What Impact Did CNC Machining Have on the World?

CNC machining has increased manufacturing productivity by speeding up processes through automation. It has improved quality and dimensional repeatability, resulting in more reliable and safer parts, and reduced the cost of producing advanced components by lowering overall labor requirements, ultimately enabling manufacturers to offer products at lower prices.

What Programming Language Do CNC Machines Use?

CNC machines use a programming language called G-code, which provides a series of XYZ coordinates for tool movements and specifies the desired tool speeds. In addition, a set of M-codes (Machine Codes) is used to control machine functions such as activating coolant, tool changes, and stopping the spindle.

Is CNC Advanced Manufacturing?

Yes, CNC machining is considered an advanced manufacturing technique because it automatically makes parts with little to no human intervention.

What Are the Different Types of CNC Machining Used Today?

CNC machining encompasses a broad range of machines with varying capabilities. At the most basic level, CNC machines can be classified as CNC lathes or CNC mills. A CNC lathe rotates the workpiece against a stationary cutting tool, while a CNC mill rotates the cutting tool against a stationary workpiece. Many machines combine both functions and the number of degrees of freedom—such as a 3-axis machine that moves the tool on the XY plane and along the Z-axis—further differentiates these systems. For more information, see our guide on the 12 Types of CNC Machines.

What Is the Difference Between NC and CNC Machining?

NC refers to the process of programming a machine with a set of machining instructions either on a punch card or on a magnetic tape. NC was developed in 1949 and is the predecessor to modern CNC (Computer Numerical Control). A machine will be said to have CNC control if it takes in a set of computer-generated codes to tell the machine where to move the tool and at what speeds in order to machine the final part.

Summary

The article reviewed the origins and history of CNC machining and its evolution from NC machining. To learn more about CNC machining and how you can use it for your projects, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.