Profile milling is a computer numerical control (CNC) machining process used to create complex external or internal contours on a workpiece. It is commonly applied to generate curved edges, 2D and 3D profiles, and precision surfaces. Profile milling operations are typically divided into four stages: roughing, semi-finishing, finishing, and super-finishing. Each stage serves a specific purpose and is selected based on the desired material removal rate, surface quality, and dimensional tolerance. Industries such as aerospace, automotive, and mold-making frequently use profile milling to achieve accurate geometries and high-quality surface finishes.

This article examines the process of profile milling, including the tools and techniques employed at each stage, as well as the key considerations in machine setup, tool path design, and material response. Attention is given to cutter selection, feed rates, tool deflection, and workholding—all of which influence milling performance and part quality.

What Is Profile Milling?

Profile milling is a CNC (computer numerical control) machining process used to create complex contours and shapes by selectively removing material from a workpiece using rotating cutting tools. It enables the production of components with non-linear geometries, precise tolerances, and high-quality surface finishes. This technique is commonly applied to parts requiring detailed edge features, curved surfaces, or multi-axis contours, particularly in the aerospace, automotive, and toolmaking industries.

What Is the Purpose of Profile Milling?

The purpose of profile milling is to create complex geometrical shapes in a workpiece and to produce components with high dimensional accuracy. Another purpose is to achieve extremely smooth surface finishes on vertical or slanted surfaces. Engine components in the aerospace and automotive industries often need this sort of dimensional precision.

What Are the Features of the Profile Mill Machine?

A profile mill machine is characterized primarily by its CNC control system and multi-axis movement capabilities, which are essential for machining complex geometries with high precision. At a minimum, three-axis movement (X, Y, Z) is required, though many modern machines offer four- or five-axis configurations to enable more advanced contouring and reduce the need for repositioning. In addition to precision control, profile mill machines are equipped with standard features common to CNC milling centers. These include robust workholding solutions (vises, clamps, or vacuum fixtures), coolant delivery systems to reduce heat and improve tool life, and chip management systems to maintain machining efficiency. Integrated safety features, such as enclosures, interlocks, and emergency stop functions, are also standard to ensure operator protection and compliance with safety standards.

How Much Does Profile Milling Cost?

The cost of profile milling depends on whether you are purchasing a CNC milling machine or outsourcing the service. Several factors—such as machine capabilities, material selection, part complexity, and production volume—can significantly affect pricing.

Purchasing a profile milling machine represents a significant investment. Typical cost ranges include:

- Entry-Level CNC Machines (3-axis): Approximately $30,000 to $100,000, suitable for basic profile milling tasks.

- Mid-Range Machines: Around $50,000 to $200,000, offering enhanced capabilities, speed, and accuracy.

- High-End Production-Grade Machines (5-axis): $200,000 to over $500,000, often used in aerospace and medical sectors for complex, high-precision parts.

These prices exclude necessary accessories such as cutting tools, workholding fixtures, CAM software, and maintenance equipment.

If outsourcing, service pricing typically reflects machining complexity, precision, material, and quantity. General pricing is as follows:

- 3-Axis Milling Services: $30 to $100 per hour, depending on complexity and location.

- 4- or 5-Axis Milling Services: $75 to $200+ per hour, often required for intricate geometries or multi-surface machining.

- Setup and Programming Fees: For one-off or prototype parts, expect $150 to $200 per hour for setup and toolpath development.

The total cost per part also depends on machining time, material waste, post-processing needs, and batch size. Larger production runs tend to reduce per-unit costs by distributing setup overhead across multiple parts.

How Does Profile Milling Differ from Traditional Milling?

Profile milling and traditional milling (also known as face milling) are two types of milling with distinct purposes. Profile milling is used to machine profiles on workpieces, while traditional milling’s purpose is to remove material consistently to flatten and smooth a workpiece’s surface.

Traditional milling can be used to cut slots or pockets into a workpiece with reasonable accuracy, but not to the complexity or precision achieved with profile milling.

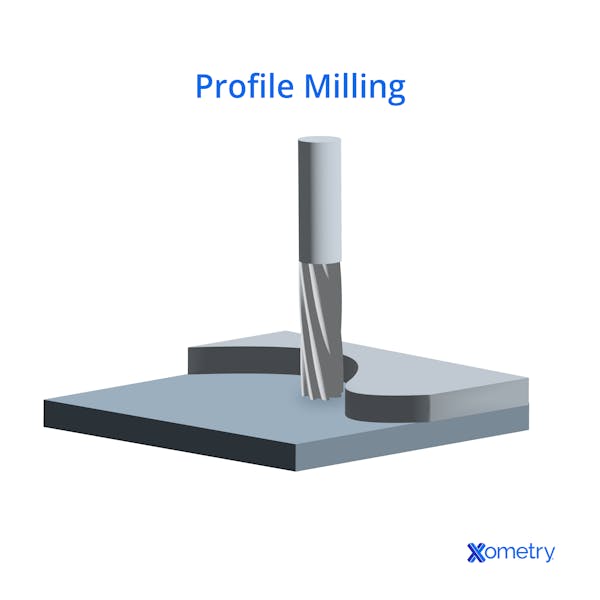

An example of profile milling

How Does the Profile Milling Process Work?

The profile milling process utilizes a CNC profile milling machine to remove material and produce a finished part. The part is designed using computer-aided drawing (CAD) software. After this, a toolpath is generated using computer-aided manufacturing (CAM) software. The toolpath instructs the machine on how and where to position the cutting tool to produce the final design.

Once the workpiece is secured to the machine and the setup is complete, the milling process will begin. Material is removed from the workpiece using rotating cutting tools attached to the milling machine. These cutting tools move across the workpiece according to the toolpath, removing small layers of material each time. Multiple passes are made until the final shape is achieved.

Profile milling consists of multiple processes, such as roughing, semi-finishing, and finishing. Each method requires different cutting tools and machine settings. The workpiece will go through all these processes before the part is considered finalized.

What Are the Different Types of Profile Milling Processes?

There are four different types of profile-milling processes:

1. Roughing/Semi-Roughing

Roughing or semi-roughing is the first step of the profile milling process. The purpose of roughing is to remove the majority of excess material quickly to produce a rough shape that is close to the final design. The roughing stage usually uses a cutting tool that can remove material efficiently, such as an end mill. This is sometimes followed by a semi-roughing stage, where a finer cutting tool brings the part closer to its final state.

2. Semi-Finishing

Semi-finishing is an intermediate step in the profile milling process, following the completion of the roughing stage. The purpose of semi-finishing is to remove some of the excess material left over from the roughing process and get the part closer to its final shape so that the finishing stage won’t struggle to remove enough material. Semi-finishing tools are typically smaller than roughing tools and have a higher number of cutting edges to remove material more precisely. Ball nose end mills are popular options.

3. Finishing

Finishing is usually the final step in the profile milling process. In the finishing stage, exact cutting tools shave the part down to its final dimensions, leaving a high-quality surface finish. High-precision cutting tools, such as ball-nose end mills, are used in this stage.

4. Super-Finishing

Super-finishing is an optional step in the profile milling process, which is used to achieve even higher-quality surface finishes and tighter dimensional accuracy. The super-finishing stage is usually employed in applications requiring extreme precision or surface finishes, such as in the aerospace industry.

What Are the Different Tools Used for Profile Milling?

Many different types of cutting tools are used in profile milling, depending on the specific milling process. Several are listed below:

1. Ball Nose Exchangeable - Head End Mills

A ball nose exchangeable-head end mill consists of a modular tool body and a replaceable ball nose cutting head. The main feature of this cutting tool is the cutting head, which can be replaced if it becomes damaged or worn out. This makes it more cost-effective than most, as the entire cutting tool does not need to be replaced.

These tools are typically used for semi-finishing and finishing operations on contoured surfaces, offering precision and reduced downtime.

2. Ball Nose Solid Carbide End Mills

Solid carbide ball nose end mills feature a fully integrated design with a radiused cutting tip, ideal for creating smooth 3D contours and complex shapes. This makes them very effective for producing shapes and finishing contoured surfaces.

Ball nose cutting tools are used primarily for the semi-finishing and finishing processes, as they can precisely remove material to make curved or contoured surfaces with excellent surface finishes.

3. Round Inserts Cutters

Round insert milling cutters use a tool body fitted with circular, indexable inserts that can be rotated or replaced when worn. These inserts typically offer multiple usable edges. This design enhances productivity and reduces tooling costs in high-volume or heavy-duty applications, especially when machining cast or irregular surfaces. They are primarily used in the roughing process, particularly on complex surfaces or cast components.

4. Indexable Ball Nose Cutters

Indexable ball nose end mills combine the contouring capability of a ball nose tool with the cost benefits of indexable inserts. These tools feature replaceable cutting tips shaped for contoured machining, making them suitable for semi-finishing and finishing operations. Indexable ball nose cutters are primarily used in the semi-finishing and finishing stages, as they are designed for the precision removal of material on contoured or curved shapes.

How To Do Profile Milling?

To carry out profile milling effectively, follow these steps:

- Design the part using Computer-Aided Design (CAD) software. Material selection should also be completed during this design phase, based on factors such as mechanical properties, machinability, and application requirements.

- Generate a toolpath using Computer-Aided Manufacturing (CAM) software. This toolpath defines the movement of the cutting tool and will be transferred to the CNC (Computer Numerical Control) milling machine for execution.

- Secure the workpiece firmly to the machine bed, ensuring proper alignment and stability to avoid vibration and positional errors during machining.

- Set up the machine and choose a cutting tool appropriate for the profile geometry, material type, and required surface finish. Tool parameters such as diameter, flute number, and coating must align with the machining goals.

- Initiate the roughing stage, during which a large volume of material is removed rapidly to approximate the final shape. This is followed by semi-roughing, semi-finishing, and finishing stages, each using more precise toolpaths and finer tools to progressively refine the surface and achieve the final dimensional accuracy and surface quality.

When To Use Profile Milling?

Profile milling is used to machine complex shapes into a component. It can also be a good finishing operation for the item’s vertical faces.

What Industries Use Profile Milling?

Profile milling is commonly used in industries that demand precise, dimensionally accurate parts with complex geometries. The aerospace industry is one of the leading industries that uses profile milling to manufacture components like aircraft engine parts. The automotive industry also uses profile milling for engine components. Profile milling is a common method for producing complex yet accurate molds and dies for injection molding and other manufacturing processes.

What Materials Are Suitable for Profile Milling?

Profile milling can generally be performed on any materials that accept traditional milling. Metals such as aluminum, steel, and brass are the most common targets; however, composites and certain plastics, including polycarbonate and nylon, are also suitable for profile milling.

What Are the Advantages of Profile Milling?

Profile milling has several distinct advantages, including:

- It produces high-precision components.

- It achieves complex geometries.

- Profile millers can create extremely smooth surface finishes.

- Parts can be produced very efficiently when compared with manual methods of creating complex shapes.

- Parts made this way are all very consistent.

What Are the Disadvantages of Profile Milling?

Profile milling has some disadvantages:

- The precision and complexity required in profile milling operations make the machinery very expensive.

- Skilled and highly trained operators are required to run and maintain profile milling machines.

- Setting up a profile milling operation can be time-consuming, especially for complex components.

Common FAQs About Profile Milling

Can Profile Mills Be Used for Cutting?

No, profile mills cannot be used for cutting in the traditional sense, such as shearing or separating materials. They cut in the sense that they use cutting tools to remove materials, but this is done to carve specific profiles into the material.

Is Profile Milling Accurate?

Yes, profile milling can be highly accurate, especially if a super-finishing process is added. This accuracy is why profile milling is popular in industries where high precision is needed, such as the aerospace and automotive industries.

What Is the Difference Between Profile Milling and Knurling?

Profile milling and knurling are two machining processes with completely distinct uses. Profile milling carves geometric shapes into materials while knurling creates a textured surface on the workpiece. Profile milling’s purpose is to produce a finished part according to a specific design, while knurling’s primary purpose is to improve grip or alter the component’s surface to have a particular texture or finish.

What Is the Difference Between Profile Milling and Grinding?

Profile milling and grinding are both machining processes that remove material, but they are distinct. The purpose of profile milling is to produce a finished component according to a geometric design. Grinding, meanwhile, is intended to generate a high-quality surface finish or to improve dimensional tolerances by removing any inaccuracies left by other machining processes.

Summary

This article presented profile milling, explained it, and discussed the process in detail. To learn more about profile milling, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including machining and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.