It's time to brush up on some engineering fundamentals, starting with the Shore A hardness scale!

Durometer, or hardness, is a material property that describes a material’s tendency to resist localized deformation or indentation. The Shore A hardness (durometer) scale is one of many durometer scales used to measure material hardness. Shore A durometers range from 0 to 100 — the higher the durometer value, the harder the material. The Shore A scale is often used in the polymer industry to aid in material selection, ensure consistent quality products, and easily compare the hardness of materials. However, it’s important to note that the hardness values of two different scales, such as Shore D vs. Shore A, cannot be compared since measured hardness values are relative to other materials using the same scale.

The Shore A durometer scale is commonly used for soft to medium-soft materials such as vulcanized and natural rubber, TPEs (thermoplastic elastomers), flexible polyacrylics and thermosets, leathers, wax, and felt. This article will define the Shore A hardness scale, its use in industry, its benefits, and its limitations.

What Is the Shore A Hardness Scale?

The Shore A hardness scale is a method used to characterize how resistant materials are to localized deformation or indentation. It is one of many scales used to measure the durometer (or hardness) of a material, typically of polymeric materials. The Shore A scale measures the hardness of a variety of materials — from soft rubbers, TPEs (thermoplastic elastomers), and silicones to semirigid plastics.

Hardness values determined using the Shore A scale are relative to the hardness of other materials that have been measured using the same scale. An empirical relationship between the depth of the indentation made in one material compared to a standard of 0 to 100% of the possible indentation depth, is used to report an empirical number known as Shore A hardness.

The Shore A hardness scale is widely used in the polymer and plastics industry to characterize the hardness of various materials. Manufacturers use durometer testing as a quality check for manufactured products. For example, silicone hardness or rubber hardness can easily be measured and evaluated against manufacturing standards. Additionally, designers use the Shore A hardness scale to compare potential materials that may be suitable for an intended application.

Benefits and Limitations of Using the Shore A Hardness Scale

The benefits of using the Shore A hardness scale are listed below:

- Allows manufacturers to determine which material is sufficiently hard (or soft) for a particular application.

- Enables easy comparison of material hardness when using the same scale.

- Gives manufacturers a tool to perform statistical process control, thus ensuring consistent quality products.

The limitations of using the Shore A hardness scale are listed below:

- Values cannot be accurately compared to hardness values obtained using other scales.

- Is only suitable for measuring non-metallic materials such as thermoplastics, thermosets, TPEs (thermoplastic elastomers), silicones, cellular materials, and waxes.

Materials That Use the Shore A Hardness Scale

The types of applications that use the Shore A hardness scale are shown in Table 1 below:

| Material | Shore A Hardness |

|---|---|

Material Gummy candy | Shore A Hardness 10 A |

Material Marshmallow | Shore A Hardness 10 A |

Material Rubber band | Shore A Hardness 20 A |

Material Gel shoe insole | Shore A Hardness 30 A |

Material Bottle nipple | Shore A Hardness 40 A |

Material Shoe sole | Shore A Hardness 70 A |

Material Tire tread | Shore A Hardness 70 A |

Material Golf ball | Shore A Hardness 90 A |

Material Shopping cart wheels | Shore A Hardness 90 A |

The Meaning of Some Common Shore A Values

- 70 Shore A means the hardness of a material is measured as “70” on the Shore A hardness scale. A tire tread is an example of a material with a 70 A hardness.

- 85 Shore A means a hardness of “85” using the Shore A scale. A hardness of 85 A would be harder than a material with 70 A. A tire tread has a hardness of 70 A while a leather belt can have a hardness of 85 A.

- 90 Shore A is a hardness measurement of “90” using the Shore A hardness scale. Shore 90 A hardness is much harder than 70 A and 85 A. Materials with 90 A are rigid and cannot be deformed by hand. An example of a material with a 90 A hardness is a caster on a shopping cart or a golf ball.

Shore Hardness Comparision With Other Scales

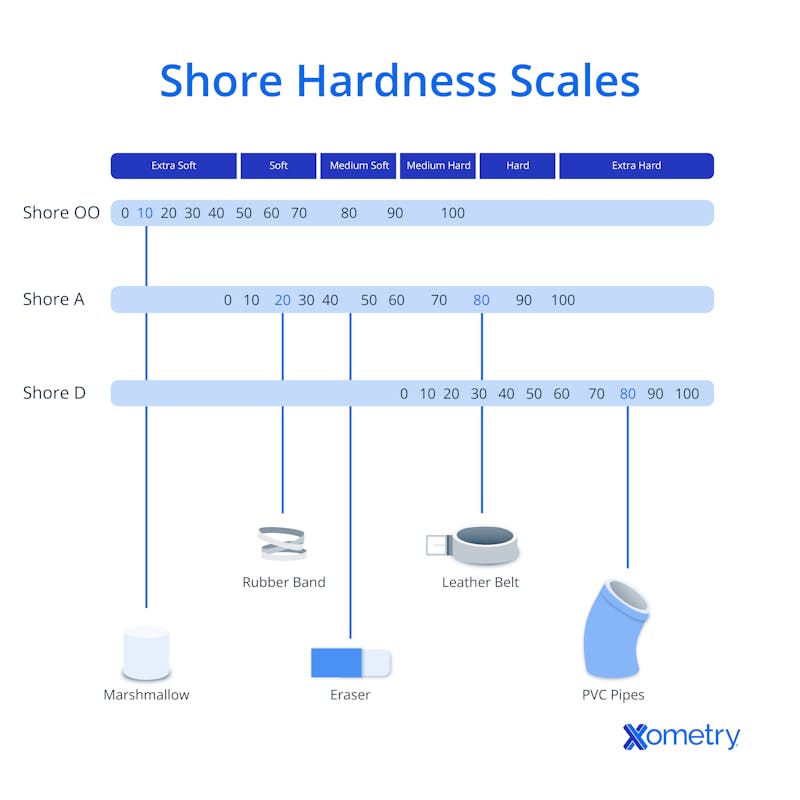

The Shore A scale and Shore D scale overlap at higher values of the Shore A scale and lower values for the Shore D scale. Lower values of the Shore A scale overlap with the Shore 00 scale. The Shore D scale starts at approximately 60 A while the Shore 00 scale maxes at about 70A.

It is important to note that hardness values should only be used as a point of reference if being compared on the same scale. Do not compare Shore A values with Shore D values to make material selections, as the slope of hardness values from 0 to 100 differ greatly between the two scales. For instance, Shore A 50 is not the same as Shore D 50. Some examples of materials whose hardness can be expressed with either the Shore A and Shore D scales are listed below:

- A tire tread can have a hardness of 70 A(~10 D).

- A leather belt can have a hardness of about 80 A (~40 D).

- A golf ball can have a hardness of 90 A(~50 D).

Xometry provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Get an instant quote today on 3D printing, CNC machining, laser cutting, and more.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.