Nylon plastic, also known as Polyamide (PA), is an engineering-grade thermoplastic. It is used in consumer goods, automotive, electronics, and more.

Even though there are different types of polyamides, all of them are characterized by high temperature, chemical, and electrical resistances due to their semi-crystalline structure. This material is durable, versatile, and exhibits relatively high tensile strength and fatigue resistance in terms of mechanical properties.

Nylon varieties differ in chemical makeup, such as Nylon 6 (PA6) made from caprolactam, and Nylon 66 (PA66) from hexamethylenediamine and adipic acid. These differences impact properties like strength, heat resistance, flexibility, and chemical resistance, tailored for various applications.

Nylon PA12 (Polyamide 12) is made from dodecanol and offers excellent chemical resistance, flexibility, and low moisture absorption. It’s commonly used in applications requiring high impact resistance, such as automotive fuel lines and flexible tubing, while offering improved durability compared to PA6 and PA66.

Glass and carbon fiber-filled variants can also enhance mechanical properties such as stiffness, tensile strength, and even heat deflection temperature (HDT).

It also possesses excellent abrasion resistance and has a low coefficient of friction. For these reasons, nylon is used extensively for bearings, sliding parts, and gears. Polyamides can also be easily flame retarded.

We're going to take a deep dive into four uses of nylon. Nylon is used for many different applications, but this article covers its use in clothing, industry, fishing nets, and machine parts. For more detailed information on Xometry's lead times, machine sizes, and more, check out our capability pages describing our injection molding services.

1. Production of Clothing

Nylon was first famously used for women's stockings at the 1939 New York World's Fair. Nylon's use increased dramatically during World War II, when the need for fabrics increased dramatically. Nylon was used to replace silk and hemp in parachutes. It was also used to make tires, ropes, tents, ponchos, and other military supplies.

At the beginning of WWII, cotton made up more than 80% of all fibers used and manufactured, and wool fibers accounted for nearly all of the rest. By August 1945, synthetic fibers had taken a market share of 25% at the expense of cotton. After the war, because of nylon and silk shortages, nylon parachute material was sometimes repurposed to make dresses.

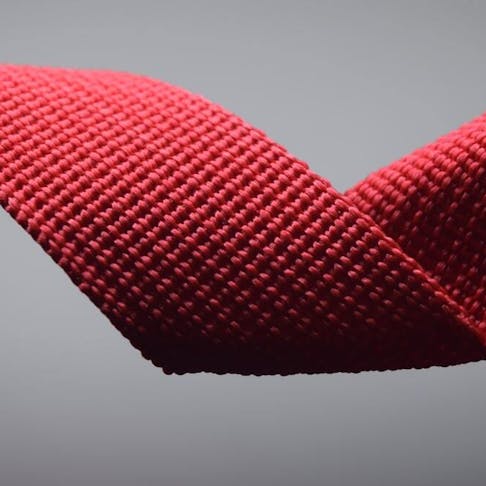

Nowadays, nylon fabric is used for shirts, foundation garments, lingerie, raincoats, swimwear, underwear, and cycling wear.

2. Industrial Manufacturing

Nylon is used for a wide range of industrial applications. It can be molded into a range of sheets and films. It is used primarily in sheets, screws, bolts, safety nets, plumbing fittings, crane pads, industrial hammer heads, and general wear-resistant applications.

Nylon can be easily melted into filaments, making it useful for 3D printing; fibers, making it useful for fabrics; films, making it useful for packaging; and sheet stock, making it useful for CNC machine manufacturing. It is also often used with injection molding.

3. Fishing Industry

Nylon is used to make fishing nets and fishing line because it is a lightweight, strong material and can withstand wear and tear. Nylon has high tensile strength, so it can hold more weight without breaking.

4. Machine Parts

Due to nylon's lightweight, durability, low friction, and resistance to heat, chemicals, and wear, it can even be used in machine parts.

Glass-filled nylon variants are used for enhanced mechanical performance in high-load applications.

Some of these parts include screws, nuts, and bolts. In addition, nylon is often used in the electronics industry for items such as circuit boards and electrical cords. Parts made of nylon are typically used in mechanisms that rotate or slide because of nylon's low coefficient of friction. It is used to make bearings for appliances because of its excellent abrasion resistance.

Benefits of Using Nylon in Manufacturing

Virtually any industry can benefit from using nylon parts, such as agriculture, construction, food processing, marine, material handling, oil and gas, sawmill, and wastewater industries.

The benefits of using nylon in manufacturing are that it has excellent abrasion and wear resistance, a low coefficient of friction, high tensile and compressive strength, and is a lightweight option that's 1/7th the weight of conventional materials. Nylon can be used to replace metal in manufacturing in applications such as gears, bushings and fasteners. For high load structural tasks, reinforced nylon composites, such as glass-filled or carbon fiber-filled variants can be used.

Nylon is also easily machined through a variety of methods.

Summary

This article took a look at four uses of nylon in different industries. Xometry offers nylon sheets and rods in a range of different sizes.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.