Whether you’re a bona fide surfer, fan of swimming, or even just a daily commuter, you’ve likely come into contact with fiberglass. This composite material can be found everywhere and a good chunk of industries rely heavily on its impressive physical and mechanical properties to make long-lasting products, like surfboards, pools, and car hoods.

At Xometry we offer instant quoting of custom machined parts made from fiberglass composites, such as garolite. If you’re interested in learning exactly what fiberglass is, its history, and many of the ways it’s used, read on.

What Is Fiberglass?

Fiberglass is a composite material that’s made of very fine glass fibers. You’ll also find it going by the names glass-reinforced plastic and glass fiber plastic. This is slightly misleading as fiberglass isn’t a pure plastic, but rather one that’s reinforced with the aforementioned tiny glass fibers.

Woven together, these glass fibers are ultra strong and can be used as an insulation or coating or used all on its own as a material. You can usually see the small fibers when looking up close at an item made of fiberglass. It’s usually clear or slightly opaque with a white tone. That said, manufacturers can dye and coat it. You’ve probably come across tan-colored belts, materials, and tapes or fiberglass products that are black, gray, white, or various other shades.

Fiberglass is a lot older than you probably would think. It’s not a recent development nor did it come about in the Industrial Revolution — it goes much further back. Ancient civilizations, including the Phoenicians and Egyptians were actually the first to develop a fiberglass of sorts. This was much rougher and rudimental than what’s used today, but it was a similar material and used mostly for decoration.

In the late 19th century, fiberglass got an upgrade. John Player came onto the scene and thought up a process that used steam jets to turn glass into weavable fibers. Other developments were made with fiberglass fabrics. But it wasn’t until the 1930s that researcher Dale Kleist concocted the material that’s most familiar to us now.

Kleist accidentally created fiberglass when welding glass blocks together, which the company Corning Glass picked up on. From then on, fiberglass was continually improved, and eventually, it became an extremely popular choice for product manufacturing. Below is an image of what fiberglass looks like up close.

How Fiberglass is Made

There are a lot of interesting ingredients that go into the successful creation of fiberglass. It’s a fantastic example of a composite material. The blend usually features certain measurements of the following materials: limestone, silica sand, soda ash, borax, magnesite, nepheline syenite, feldspar, kaolin clay, and alumina. Glass is also essential, and resin is often thrown into the mix, too.

After you have the right weight and measurements of each ingredient, you’ll blend them and place them into the furnace for melting. This process creates molten glass that can be cut into fibers and wound up and lengthened into long filaments or chopped up and used in sheets, insulation, or coatings.

Once it’s created, fiberglass typically has a density of between 2.4 and 2.76 g/cm3. The time it takes to manufacture will depend on the type of fiberglass you’re using, what application it’s being used for, how long it takes to cure, and the quantity being made.

Why it’s an Important Material in Manufacturing

You might be wondering why manufacturers would choose fiberglass over something else. There are a few reasons that make it a solid choice. Fiberglass is lighter but stronger when it’s up against other materials. It’s also completely fine when facing harsh conditions, and it won’t buckle or warp. These helpful perks are why you could use it for both a pool and a circuit board.

The Different Types of Fiberglass

Your choice of fiberglass isn’t limited to one or two types. There are many different kinds, so we’ve broken down the basics of 12 of them below to help you choose which will serve you best.

1. E-Glass Fiber

It’ll come as no surprise that E-glass or electrical glass, is superb for insulating electrical components. You’ll find it used in aerospace and industrial products because it’s lightweight and heat resistant. The concoction you’ll need for this type of fiberglass includes silica, soda, potash, lime, boric oxide, magnesia, and alumina.

2. D-Glass Fiber

When you’re working with electrical appliances, optical cables, and cookware, you’ll want to rely on D-glass fiber. It can insulate these types of items because of its low dielectric constant. The star ingredient in this type of fiberglass is boron trioxide.

3. R-Glass Fiber (Also Known As T-Glass or S-Glass Fiber)

Fiberglass already offers a pretty impressive resume of characteristics, but if you need something that performs even better, R-glass fiber is the one. You also might find it by the T-glass or S-glass, and because of its acidic and tensile strengths, it’s usually found in products made for aerospace and defense industries.

4. A-Glass Fiber

This type of fiberglass is one you may come across in your everyday life. A-glass also goes by soda-lime glass or alkali glass, and it’s often turned into bottles, jars, and window panes. It’s relatively cheap compared to other options, has chemical stability, and you can recycle it. In its mixture, you’ll find lime, alumina, dolomite, soda, silica, and sodium sulfate.

5. Advantex Glass Fiber

Advantex glass is trademarked, and it’s a version of the material you’d look to if you’re worried about corrosion caused by acids and temperature changes. That’s why it’s popular for manufacturers in the mining and oil industries. It’s also found in places with the harshest and grimiest conditions, including power plants and sewage systems. You can expect to find a lot of calcium oxide in its makeup.

6. ECR Glass Fiber

If you’re after something similar to E-glass fiber but with extra heat and acid resistance, ECR glass fiber is the next step up. It’s an environmentally friendly fiberglass that’s great if you’re looking to make durable panels that can handle water, heat, and impact without struggling.

7. C-Glass Fiber

C-glass also goes by chemical glass, and as you’d assume, it’s the perfect fiberglass if you need materials that are impact and chemical-resistant. The calcium borosilicate in its makeup won’t let you down if you use it in environments (like pipes and tanks) that are exposed to water and chemicals.

8. Z-Glass Fiber

When you’re in need of a fiberglass that can provide heavy-duty reinforcements for concrete and other materials, you can look to Z-glass products like mesh. These have no problem handling acids, salt, wear and tear, and UV rays.

9. S2 Glass Fiber

This type of fiberglass is unique in that it can support you with reinforcing textiles. It’s a high-performing pick with unbeatable temperature resistance, compression, and impact resistance. You can even make aerospace cloth with it.

10. AR-Glass Fiber

You may also call AR glass alkali-resistant glass. It gets mixed in with concrete to prevent or at the very least slow down cracking. This flexible fiberglass is strong and won’t falter if you need a material that won’t succumb to water or changes in the pH. To get it to this level, it has zirconia in its blend of ingredients.

11. M-Glass Fiber

Fiberglass may not sound like it could be truly that flexible, but M-glass fiber will happily prove you wrong. It has plenty of elasticity and beryllium in its formulation, which means it’s a great option for making tableware, glassware, packaging, housing, and building materials.

12. AE Glass Fiber

Just when you thought there couldn’t be any more applications for fiberglass, the AE glass type arrives. It may sound niche, but it’s a popular material for monitoring and filtering air. Its fibers cut down and trap unwanted particles without completely slowing down its flow rate. Whether you work in a lab or an environmental sector, you’ll probably be aware of this type.

Available Formats

Here are the most common formats you’ll want to be aware of when it comes to fiberglass.

- Woven fabrics: Fiberglass can come in a fabric format, which may be unexpected if you’re used to hard fiberglass products. You can find it in satin, twill, and plain weaves and can choose based on the finish you’d like. This kind of material is great for surfboards, boats, and car parts.

- Chopped strand mat: Also known as CSM, you can find this thick version of fiberglass particles bound up together in rolls. It’s usually tapped on for lay-up and spray-up processes or any situation where you need strength and the ability to wet.

- Tow and roving: If you’ve worked with fiberglass before, you’ll probably be familiar with tow and roving. You can manually unravel these spools or feed them through machines to create parts for aerospace, marine, automotive, or construction industries.

- Veil mats: These mats are thin and lightweight, which makes them a great selection if you want to make composite panels, automotive parts, or anything where corrosion is possible.

Properties of Fiberglass

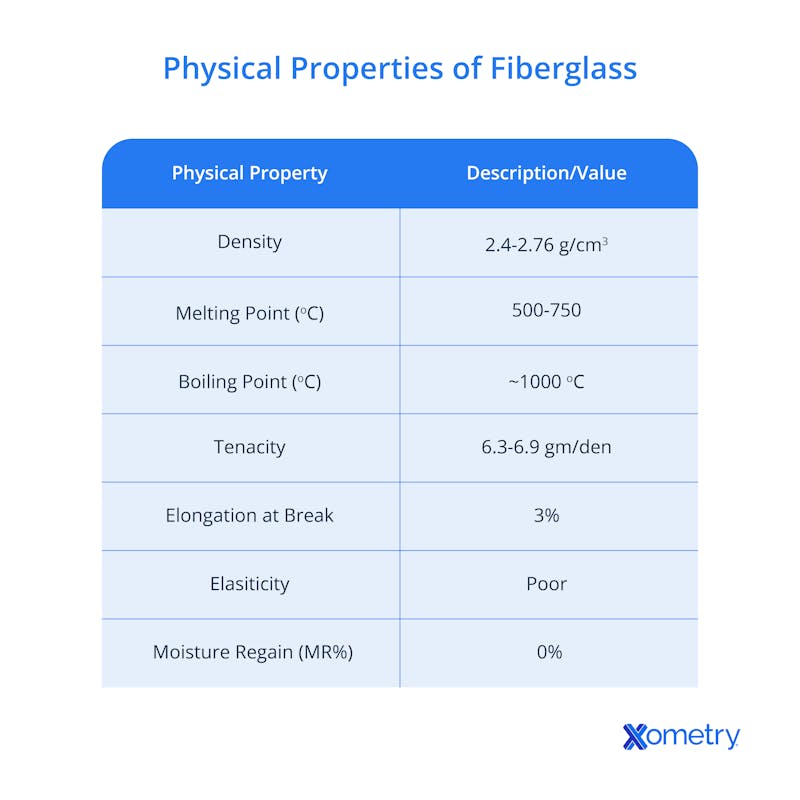

The following charts depict the mechanical, physical, and chemical properties of fiberglass.

| Physical Property | Density (g/cm3) | Tensile Strength (GPa) | Young’s Modulus (GPa) | Elongation | Coefficient of Thermal Expansion (10-7/°C) | Poisson’s Ratio |

|---|---|---|---|---|---|---|

Physical Property E-glass | Density (g/cm3) 2.58 | Tensile Strength (GPa) 3.445 | Young’s Modulus (GPa) 72.3 | Elongation 4.8 | Coefficient of Thermal Expansion (10-7/°C) 54 | Poisson’s Ratio 0.2 |

Physical Property C-glass | Density (g/cm3) 2.52 | Tensile Strength (GPa) 3.31 | Young’s Modulus (GPa) 68.9 | Elongation 4.8 | Coefficient of Thermal Expansion (10-7/°C) 63 | Poisson’s Ratio - |

Physical Property S2-glass | Density (g/cm3) 2.46 | Tensile Strength (GPa) 4.89 | Young’s Modulus (GPa) 86.9 | Elongation 5.7 | Coefficient of Thermal Expansion (10-7/°C) 16 | Poisson’s Ratio 0.22 |

Physical Property A-glass | Density (g/cm3) 2.44 | Tensile Strength (GPa) 3.31 | Young’s Modulus (GPa) 68.9 | Elongation 4.8 | Coefficient of Thermal Expansion (10-7/°C) 73 | Poisson’s Ratio - |

Physical Property D-glass | Density (g/cm3) 2.11–2.14 | Tensile Strength (GPa) 2.412 | Young’s Modulus (GPa) 51.7 | Elongation 4.6 | Coefficient of Thermal Expansion (10-7/°C) 25 | Poisson’s Ratio - |

Physical Property R-glass | Density (g/cm3) 2.54 | Tensile Strength (GPa) 4.135 | Young’s Modulus (GPa) 85.5 | Elongation 4.8 | Coefficient of Thermal Expansion (10-7/°C) 33 | Poisson’s Ratio - |

Physical Property EGR-glass | Density (g/cm3) 2.72 | Tensile Strength (GPa) 3.445 | Young’s Modulus (GPa) 80.3 | Elongation 4.8 | Coefficient of Thermal Expansion (10-7/°C) 59 | Poisson’s Ratio - |

Physical Property AR glass | Density (g/cm3) 2.7 | Tensile Strength (GPa) 3.241 | Young’s Modulus (GPa) 73.1 | Elongation 4.4 | Coefficient of Thermal Expansion (10-7/°C) 65 | Poisson’s Ratio - |

Table Credit: https://www.researchgate.net/publication/265346634_Glass_fiber-reinforced_polymer_composites_-_A_review

| Chemical Property | Description |

|---|---|

Chemical Property Acid | Description Hydrochloric acid and hot phosphoric acid can damage glass fibers. |

Chemical Property Bases | Description It is sufficiently resistant to alkali. |

Chemical Property Bleach | Description Bleach does not harm fiberglass. |

Chemical Property Organic solvent | Description Organic solvents do not change their composition. |

Chemical Property Mildew | Description It is not affected by mildew. |

Chemical Property Insects and rodents | Description It is unaffected by insects and rodents. |

Chemical Property Dyes | Description It cannot be colored after production but can be colored before production by adding a dye to the solution bath. |

Chemical Property UV radiation | Description It can change color due to UV exposure (yellowing), but the other properties remain unchanged. |

Chemical Property Fire | Description Good fire resistance. |

Chemical Property Rotting | Description Fiberglass does not rot. |

Table Credit: https://textilefashionstudy.com/physical-chemical-properties-of-glass-fiber/

The Characteristics of Fiberglass

Fiberglass has a variety of useful characteristics. For example, we offer fiberglass composite materials like garolite G-10 FR-4, which is known for its fire retardancy. Here are some of the most common characteristics of fiberglass materials.

- Durable

- Stiff

- Lightweight

- Fire-resistant

- Excellent insulator

- Great chemical resistance

- Highly corrosion resistant

- Dimensionally stable

- Temperature and humidity-resistant

- Resistance to warping

- Moisture resistant

Applications for Fiberglass

Think you can name all the ways that fiberglass can be used? Take a look at this long list of products and applications where fiberglass plays a part.

- Swimming pools

- Boats

- Aircraft

- Surfboards

- Automobiles

- Storage tanks

- Septic tanks

- Piping

- Insulation

- Sports equipment

- Bathtubs and hot tubs

- Casts

- Helmets

- Electronics

- Wind turbine blades

Advantages and Disadvantages

If you want to weigh up the advantages of fiberglass, first you’ll want to note that one of its main benefits is its strength. Actually, fiberglass has more tensile strength than steel, but it’s still lightweight. It’s a great material if you need something that’s resistant to weather, water, and corrosive chemicals. It’s not conductive or magnetic, which earns it points when it comes to insulation and using it around other kinds of materials. You’ll also find that fiberglass doesn’t rust, shrink, burn, or expand, making it durable and long-lasting.

Any material will have its limits though, including fiberglass. One of the disadvantages you may find with using it is that it’s expensive, especially when compared to non-composite materials. Fiberglass is also hard to get rid of and doesn’t biodegrade, which isn’t ideal if you’re invested in sustainable practices. If you have employees working with fiberglass, it can be hazardous to touch and breath in if the right safety equipment isn’t worn. With too much sunlight, you may also find that fiberglass fades.

Copyright and Trademark Notice

- Advantex® is a registered trademark of Owens Corning

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.