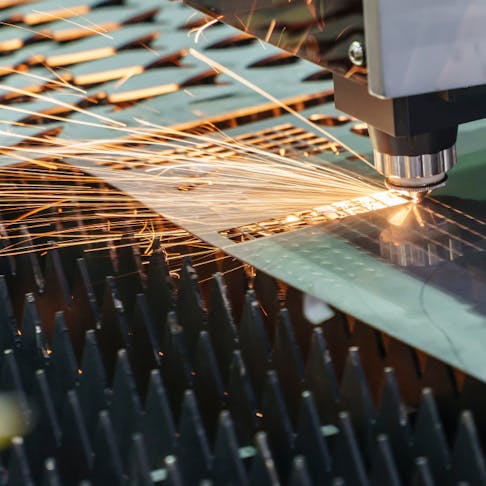

Laser engraving is the process of creating patterns and designs on parts by vaporizing material. The advantage of laser engraving is that the process leaves marks on the part that are both precisely formed and wear-resistant. Laser engraving can be used for a variety of applications, including: personalized gifts, trinkets, product branding, and barcodes. This article will describe the 11 best laser engravers for metal.

1. xTool D1 Laser Engraver

At a price of $699, the xTool D1 Laser Engraver offers an entry-level diode laser system with a 400x400 mm work area. The laser has a spot size of 0.08x0.06 mm, which can create high-resolution engravings. Two stepper motors provide precise movement and speed (over 8890 mm/min) control along the XYZ axes. An integrated fan helps cool the workpiece during laser engraving. The machine is easy to set up, making it simple to get started with laser engraving. The xTool D1 is compatible with two popular laser control programs: LaserGRBL and LightBurn.

2. Trotec SpeedMarker 1300

The Trotec SpeedMarker 1300 is a fiber laser with a work area of 990.6x457.2 mm. Its XYZ movement is controlled by a gantry system. It is offered in 20-50 W varieties. Additionally, rotary engravings can be accomplished because of an integrated attachment. Alternatively, SpeedMarker 1300 can be outfitted with a MOPA fiber laser available in 20-100 W varieties. This MOPA option can easily engrave any metal because of its short wavelengths and high power rating. A MOPA fiber laser head is capable of creating colored laser engravings on materials like aluminum or stainless steel. The Trotec SpeedMarker 1300 is the best metal laser engraver for industrial applications, so it is not surprising that it is also among the more expensive, at well over $50,000.

3. Atomstack X7 Pro

The Atomstack X7 Pro is a budget-friendly, metal-capable, 10 W diode laser engraver that costs $479. Its work area is 410x400 mm. The X7 Pro has a spot size of 0.06x0.06 mm and an engraving accuracy of around +0.01 mm. A fan helps blow debris off the engraved surface during cutting. The laser system’s XY movement is controlled by a stepper motor and a synchronous belt drive system, while the Z-axis is controlled manually by a knob. A rotary attachment can be purchased to enable engraving on rounded surfaces. The Atomstack X7 Pro is compatible with LightBurn and LaserGRBL software.

4. LaserPecker 2

At $1200, the LaserPecker 2 engraver is more expensive than other entry-level engravers, but makes up for it with a robust set of available features. The basic system is a small, portable 5 W diode laser engraver that is easy to assemble. Its simple, intuitive plug-and-play interface also makes it easy to set up and start engraving. The LaserPecker 2 can engrave at speeds up to 3600 mm/min and has an integrated rotary attachment for cylindrical laser engraving. Other features include a fan that cools the part and blows debris away and a 20,000 Ah power bank that can power the engraver for up to 200 minutes without an electrical supply line.

5. Atomstack A5 Pro

The Atomstack A5 Pro costs $470 and has a work area of 410x400 mm. It’s a 5 W diode laser system that has a spot size of 0.08x0.06 mm and an engraving accuracy of +0.01 mm. A lead screw facilitates the laser head’s movement along the X-axis while a drive belt and rail guide the motion on the Y-axis. This enables the laser module to move at a rate of up to 430 in/min. The Atomstack A5 Pro is compatible with LightBurn and LaserGRBL software.

6. Atomstack S20 Pro

The Atomstack S20 Pro is a 20 W diode laser that has a work area of 400x400 mm. At $900, this engraver has a laser beam with a spot size of 0.08x0.1 mm. This system can engrave with an accuracy of +0.01 mm and can move up to 11,938 mm/min. Stepper motors and a lead screw control XY movement, while Z movement is set manually. The machine can be operated offline — removing the need for it to be connected to a network to engrave. The Atomstack S20 Pro is compatible with both LightBurn and LaserGRBL software.

7. Ortur Laser Master 3

The Ortur Laser Master 3 is a 10 W diode laser that costs $700. It has a work area of 15.75x15.75" and a tight spot size of 0.05x0.01 mm that has an accuracy of +0.0008 mm. This spot size results in high-quality engravings. Belt drives powered by stepper motors control the XY movement of the laser while the Z movement is set manually. The Laser Master 3 is compatible with LaserGRBL, LightBurn, and Laser Explorer software.

8. Ortur Laser Engraver, Laser Master 2 S2 SF

At $450, this machine is the cheapest on this list. The 1.6 W diode laser system’s XY movement is controlled by stepper motors and a belt drive. It can move at up to 15000 mm/min. The Z-axis is set manually. The machine has a work area of 400x400 mm and a spot size of 0.05x0.1 mm. At 7.8 lb, this machine is also one of the lightest on this list.

9. OMTech FM1212-50S

The OMTech FM1212-50S is a 50 W fiber laser system that costs $5300. It can engrave with exceptional precision at tolerances of +0.0001 mm and incredible speeds of up to 6985 mm/sec. Rather than a series of motors that control the XY movement of the laser, the galvo laser head uses a series of mirrors to position the laser spot. Z-axis movement is controlled manually. The OMTech FM1212-50S has an engraving area of 7.9x7.9”, which makes it ideal for small workpieces. The engraver comes with dedicated software called EZCAD2.0, which essentially functions like LightBurn and LaserGRBL.

10. 80W RECI W8 and 80W RECI W2 Hybrid Metal Laser Cutter / Laser Engraver

The RECI W8 costs $17,200 and has both a 180 W CO2 laser for cutting and an 80 W CO2 laser for engraving. It can be used for both non-metallic and metallic materials. It has a large work area of 1300x900 mm on an electric drive lifting workbench. The laser autofocuses, so there is no need to manually adjust the Z-axis. The movement of the XY axes is controlled by a servo motor and a guide rail. The laser system can engrave at speeds up to 60,000 mm/min. The Reci W8/W2 hybrid laser machine is compatible with common CAD software such as AutoCAD or CorelDRAW.

11. Epilog Fusion Pro 24

The Epilog Fusion Pro 24 is a hybrid laser system that costs well over $10,000. It comes with a 60 W CO2 laser that works best for nonmetals, and a 30 W fiber laser for metals. The system has a large work area of 609.6x609.6 mm”, and a maximum Z-axis depth of 228.6 mm. The Epilog Fusion Pro 24 can produce high-resolution engravings with a maximum resolution of 1200 DPI (dots per inch). The machine’s XY movement is controlled by a belt drive that is powered by servo motors, while its Z-axis is set manually. The high-quality servo motors allow the laser head to move at a pace of 4191 mm/min. The Fusion Pro 24 uses integrated laser software developed by Epilog.

How To Choose The Best Laser Engraver for Metal?

The list of steps below describes how to choose the best laser engraving machine for metal:

- Consider which metals will be engraved using the machine. The properties of the work material will affect the laser power and laser speed required.

- Think about the size of the workpiece material and the size of the area to be engraved. Larger workpieces may require larger work areas or may require several successive setups when using a smaller machine.

- Consider the number of pieces in a production run. Fiber lasers are the most efficient for laser engraving metal, and would be best for high-volume jobs, but are the most expensive type of laser.

What Are the Factors To Consider in Choosing the Best Laser Engraver?

The list below describes some factors to consider when choosing the best laser engraving machine for metal:

- Material properties such as: vaporization temperature, reflectivity, and density

- Workpiece size and size of engraving area

- Production volume

- Capital budget

For more information, see our guide on Laser Engraving.

What Is the Cheapest Laser Engraving for Metal?

The cheapest laser engraving machine for metal is the Ortur Laser Engraver, Laser Master 2 S2 SF. It costs $300 because of its laser optics that produce a relatively larger spot size. The motors that propel its movement are a bit slower and not as accurate as others. However, it can still produce high-quality metal engravings.

What Is the Most Expensive Laser Engraving for Metal?

The most expensive laser engraving machine for metal is the Trotec SpeedMarker 1300. This machine is expensive due to: the fiber optics that produce its powerful laser beam; its large work area and machine footprint; its integrated rotary attachment for round-part engraving; and the systems that facilitate the laser head’s movement. This machine is best for large manufacturing operations.

What Is the Lifespan of Laser Engraver for Metal?

A laser engraving machine generally lasts between three and ten years depending on: the make and model of the laser, frequency of use, the materials it is used to engrave, and how well it is maintained throughout its life.

How To Laser Engrave Metal

The list below describes the steps in laser engraving metal:

- Select the metal to be used for the engraving project based on the product's requirements. The type of metal selected will impact the laser power and engraving speeds that are possible.

- Convert the design file into a format (usually .dxf or similar vector-based format) that can be read by the software on the laser system.

- Establish the power, speed, and pulses per inch (PPI) settings required to engrave the selected material. Adjust the focus of the laser to be on the surface of the workpiece.

- Some highly reflective metals, such as copper and titanium, require metal marking spray or paste to be applied before engraving.

- Secure the workpiece so it does not move during engraving.

- Ensure proper ventilation to remove fumes, and that personal protective equipment (PPE) is worn.

- Initiate the laser engraving process. Post-processing may be necessary to remove debris and clean the finished part.

How Much Power Is Needed To Run a Laser Engraver To Engrave Metals?

Generally, lasers that have high power (>25W) are the most efficient for laser engraving metal. Lasers with power ratings as little as 1W can engrave metals but may require several passes to achieve desired results.

What Type of Laser Is Best for Metal Engraving?

Fiber lasers are best for metal engraving because fiber lasers emit short wavelengths in the blue, violet, and ultraviolet spectrums. These wavelengths are readily absorbed by metals and make laser cutting and engraving with fiber lasers easy. For more information, see our guide on Types of Lasers.

What Is the Best Metal To Laser Engrave?

Aluminum is the best metal to laser engrave because aluminum has a relatively low vaporization temperature (4221°F/2327.2°C compared to other metals. Bare aluminum, anodized aluminum, and powder-coated aluminum all readily absorb wavelengths from the main types of lasers including fiber, CO2, and diode.

What Metal Should You Not Laser Engrave?

Metal laser engraving shouldn’t be used on beryllium oxide. Laser cutting beryllium oxide causes dust and contaminants that are damaging to the optics of a laser system and pose a risk to the health of the laser system user.

Metal laser engraving shouldn’t be used on stainless steel. It removes the material’s outer protective layer and exposes bare steel to oxygen in the environment. This allows rust to form and proliferate under the surface of the part, making the stainless steel weaker over time.

What Are the Advantages of a Laser Engraving Machine for Metal?

The advantages of a metal laser engraving machine are listed below:

- It is an efficient and eco-friendly way to create elaborate logos, pictures, and patterns on parts.

- It can be used on a wide range of materials.

- It is highly precise compared to other marking methods.

What Are the Disadvantages of a Laser Engraving Machine for Metal?

The disadvantages of a metal laser engraving machine are listed below:

- Laser engraving metals requires operators to be trained on how to use the machine. They must be knowledgeable about the effects that different laser parameters can have on the resultant engraving.

- Upfront costs, maintenance costs, and the cost of operation for laser engraving can be a barrier for some users and companies.

Is Laser Engraving the Same As Laser Etching?

No, laser engraving is not the same as laser etching. Laser engraving involves cutting marks into the part by vaporizing material away while laser etching creates marks at the surface of the part by melting material.

Summary

This article presented the best laser engravers for metal, explained what they are, and discussed the different features of each. To learn more about laser engravers for metal, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.