CO2 (carbon dioxide) lasers are the highest-power continuous wave lasers. They are widely used in both medical and industrial applications. “Laser” is an acronym for Light Amplification by the Stimulated Emission of Radiation. A CO2 laser works by exciting CO2 molecules to generate a coherent beam of light at a specific frequency, typically between 9,300 and 10,600 nm. The CO2 laser was invented in 1964 at Bell Laboratories by Kumar Patel. In the medical industry, the CO2 laser is predominantly used for skin treatment using a process called carbon dioxide laser resurfacing. The CO2 laser is also very popular in industrial applications for cutting and welding a wide range of materials from steel to fabric.

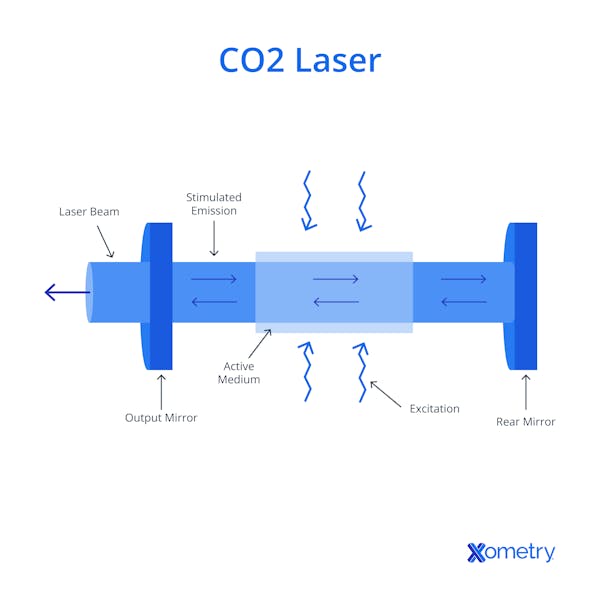

How Does a CO2 Laser Work?

The operating principles of a CO2 laser can be broken down into a number of steps, beginning with the generation of the laser beam. This is performed inside the resonator, a cylindrical glass tube filled with carbon dioxide, nitrogen, and helium. The resonator has a reflective mirror on one end of the tube and a semi-reflective mirror on the other. The gas in the resonator tube is ionized by an electric field which causes the nitrogen molecules to become energized. This energy is then passed on to the CO2 molecules, causing the electrons to move to a higher energy level. The excited CO2 molecules emit photons when the electrons fall back to a lower energy level. The instability caused by an emitted photon can cause nearby excited CO2 molecules to emit photons as well. This creates a chain reaction of photons that move in the same direction as the photon that disturbed them. Excited photons will strike one of the mirrors perpendicularly and then begin to bounce between the two mirrors, causing other excited CO2 molecules nearby to emit yet more photons in the same direction. This process continues until enough photons are reflected back and forth between the two mirrors such that the energy contained in this wave is sufficient to pass through the semi-reflective mirror as a coherent beam of light. This light is then directed into a lens that focuses the beam into a point of high energy intensity that can be used for industrial or medical applications.

What Are the Benefits of Using a CO2 Laser?

A CO2 laser is a highly precise tool whose energy intensity can be anywhere from a few milliwatts to a few thousand kilowatts. Some of the benefits of a CO2 laser are listed below:

- CO2 lasers can be focused on very narrow points with diameters as small as 100 microns, thereby allowing for very precise application of energy for cutting as well as for precise medical procedures.

- CO2 lasers do not experience any reaction loads when cutting. Thus, their precision depends only on the accuracy of the laser head position motors or in the case of a medical practitioner, the steadiness of their hand.

- CO2 lasers can be used on a wide variety of different materials including: metal, tissue, wood, plastic, and diamond. Applications can include cutting metal, artistic engraving, medical resurfacing as well as industrial rust removal from metal.

- CO2 lasers can cut at high speeds, especially if a high-energy laser is used. The beam can also change targets extremely quickly when making use of a mirror that is directed with highly accurate servo motors.

- CO2 lasers can be easily automated, especially in the industrial sector. In fact, the speed with which lasers can cut necessitates automation to achieve optimal efficiency.

What Are the Risks of Using a CO2 Laser?

CO2 lasers are extremely dangerous, as the laser beam carries enough energy to injure users, patients, and damage equipment. Some common risks are listed below:

- Materials with low ignition points like wood, paper, and some plastics can easily catch fire when exposed to high-energy CO2 laser beams.

- Some materials, like PVC, will generate a toxic gas when exposed to a CO2 laser.

- Eyes can be permanently damaged by CO2 lasers if they are directly or indirectly (via reflections), exposed to the beam.

- When used in medical applications lasers can produce a wide range of side effects such as infections, or hyperpigmentation.

What Are the Possible Side Effects of CO2 Laser Treatment?

CO2 laser treatment encompasses a number of surgical and dermatological methods. The most common application is for laser resurfacing, the process of using a laser beam to remove a superficial layer of skin. Laser treatment has many benefits. Like any medical treatment, it also has some risks and side effects, as listed below:

- Bacterial, viral, and fungal infections are all relatively uncommon potential side effects of laser treatment. In many cases, medications are prescribed to prevent infections from developing.

- While CO2 laser treatment is used for scar removal, laser treatment can sometimes result in limited scarring.

- Skin peeling usually occurs after carbon dioxide laser resurfacing, but is not permanent and will dissipate over time.

- Skin redness is a normal side effect of carbon dioxide laser resurfacing. It usually disappears after the skin has healed properly.

- Milia is a post-laser treatment side effect that presents as many small bumps on the skin. This is a common side effect and is typically treated with a topical cream.

- Hyperpigmentation is a common effect of CO2 laser treatment and is typical in people with Fitzpatrick skin types III and IV. It often occurs after ablative laser treatment due to differences between new and old skin.

What Is the History of CO2 Laser Cutting?

CO2 laser cutting was first developed in 1964. The CO2 laser was based on decades of research that started with the development of the optical MASER (Microwave Amplification by Stimulated Emission of Radiation) by Charles Townes. However the wavelength of the MASER was too large for effective industrial use and a near-infrared laser was developed, the first person to coin the term LASER (Light Amplification by the Stimulated Emission of Radiation) was Gordon Gould who improved on the optical resonator envisioned by Arthur Schawllow. At the time it was invented, this laser was the most powerful continuous wave laser. It opened the door for industrial use. In 1964, the first CO2 laser cutter was used in combination with oxygen to successfully cut a 1 mm thick metal sheet.

Who Invented the CO2 Laser?

Kumar Patel developed the CO2 laser while he was working at Bell Laboratories. Kumar Patel was an Indian-born engineer who earned a Ph.D. in electrical engineering from Stanford University. A mere three years after joining Bell Labs, Patel discovered the effectiveness of CO2 in generating a coherent beam, or laser. This research paved the way for the CO2 laser, widely used in both the medical and industrial fields today.

What Are the Different Types of CO2 Laser Cutting?

There are three main types of CO2 laser cutting methods, as described below:

- Melt and Blow: The laser beam will first heat the material until it has reached a liquid state. Then, a jet of high-pressure, non-reactive gas like nitrogen is used to blow the molten material out of the area being cut. This method allows for lower energy use to achieve the same cut depth.

- Reactive Cutting: This process is generally used on materials that are easily oxidized, such as steel or titanium. The laser beam heats up a localized area, and a high-pressure stream of oxygen is directed onto this area. This oxygen essentially causes the metal to oxidize and burn. The metal oxides are then blown from the cut by the oxygen stream.

- Vaporization Cutting: This process does not make use of any high-pressure gasses. It relies solely on the heat energy from the laser beam to sublimate the material being cut. This means that the heat causes the material to transition directly from a solid phase to a gas phase. This process is only possible with materials that have low vaporization temperatures, like plastic.

What Are the Uses of a CO2 Laser?

CO2 lasers are widely used in the industrial and medical fields. Listed below are some of their common uses:

- CO2 lasers are used for medical applications to treat various skin problems, from scar removal to pre-cancerous skin lesions.

- Precisely controlled CO2 lasers can be used to cut tissue in place of traditional scalpels. This application has the added effect of immediately cauterizing blood vessels in the area being cut.

- CO2 lasers are used to fuse metal and plastic powder together to form 3D-printed parts.

- Laser cutters are widely used to cut both sheets and plates in a wide variety of materials, including metals, plastics, and wood.

- Laser cutters can be used to mark almost any material. This capability can be used to add serial numbers to manufactured parts, or for more artistic applications like wood engraving.

- Laser welding is a method to precisely join two metals or thermoplastics together using a laser beam instead of an electrical arc.

What Are the Types of CO2 Lasers?

Two main types of CO2 lasers are used for medical l applications: ablative and fractional. Treatment with fractional CO2 lasers has become the preferred method of laser skin treatment because it causes fewer post-treatment complications.

1. Ablative CO2 Laser

Ablative CO2 laser treatment refers to the process of adding energy to a continuous area of skin tissue by making use of a pulsed laser. This energy addition increases the temperature of the water present in the tissue to the point where it essentially ablates away the tissue. A single laser pulse can be any length at all up to 50 ms. The ablative laser is used to treat a wide range of skin health issues, from benign tumors to burn scars. After treatment, a new layer of healthy skin tissue will grow back in place of the undesirable tissue.

2. Fractional CO2 Laser

Fractional CO2 laser treatment refers to the process of breaking up the main laser beam into many tiny beams as if it had been passed through the mesh of a window screen, allowing only separated "mini-beams" to impact the treatment area. Fractional CO2 laser treatment is different from ablative treatment as it does not affect a large continuous surface area of tissue but rather selectively focuses on specific discrete areas or points to create microscopic columns of destroyed cells in the skin. The fractional nature of the treatment means that less skin is damaged by the laser when compared to ablative treatments which reduce the pain of the treatment, promote more effective healing, and result in fewer post-treatment complications. Fractional laser treatment can be further categorized as deep ablative, where the skin tissue is vaporized. Instead of a large continuous area, only individual unconnected columns of skin tissue are affected. Another categorization is non-ablative, where the top layers of skin are not damaged but the tissue underneath is thermally injured by making the focal point of the laser to be underneath the surface of the skin. The skin is damaged in discrete points which help promote the healthy regrowth of tissue.

Why Is a CO2 Laser the Highest-Power Laser?

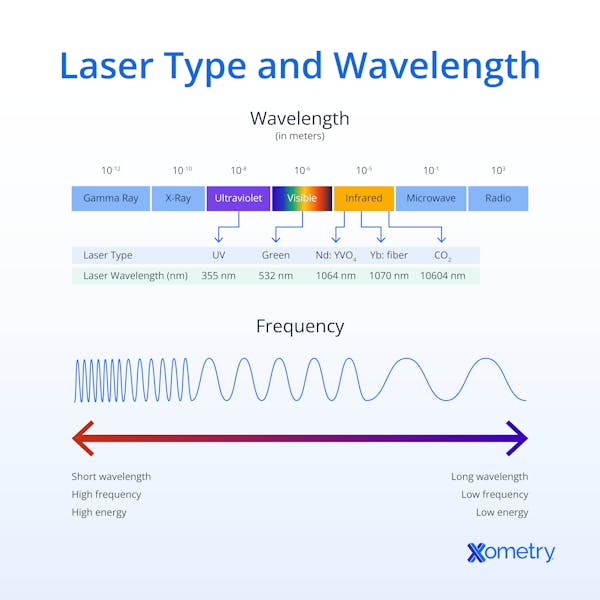

A CO2 laser is a highest-power laser because its light energy is easily transmitted through the air and efficiently absorbed by many materials. The CO2 laser's wavelength range of 9,000 to 10,600 nm is optimal for atmospheric transmission, allowing 80% of the laser light to reach its destination. Because so many materials readily absorb these wavelengths, instead of transmitting or reflecting them, the laser energy that reaches a target surface is more effective at heating the material. Water is especially prone to absorbing these wavelengths. This is why a laser can cut or ablate living tissue so easily.

What Does the Term “Continuous-Wave Laser” Mean?

The term "continuous-wave laser" refers to a laser whose power output is constant over time. The energy from a pulsed laser, on the other hand, is repeatedly turned on and off under computer control. The two approaches to delivering the energy from a CO2 laser produce different effects and are used for different applications. Continuous CO2 lasers are used for ablative skin treatment of acne and wrinkles. Pulsed CO2 lasers are used for treating dilated blood vessels.

What Is the Range of CO2 Laser Wavelengths?

Most industrial CO2 lasers designed to cut metal have a wavelength of 10,6000 nm, which is the most commonly used wavelength. For medical applications, a CO2 laser with a wavelength of 9,300 nm is commonly used. This wavelength is readily absorbed by water and has shallow penetration, making it ideal for surgery on the skin. Wavelengths as high as 10,600 nm are used for some medical and dental applications.

Does a CO2 Laser Produce Radiation?

Like any energy source, a CO2 laser does emit radiation. However, CO2 lasers do not produce high-energy radiation like gamma rays, x-rays, or alpha or beta particles collectively referred to as "ionizing radiation." Instead, CO2 lasers radiate non-ionizing infrared energy. Because infrared wavelengths produce heat, uncontrolled exposure to CO2 laser emissions has the potential to damage the eyes and skin. Special caution is required because CO2 laser wavelengths are not visible to the human eye.

Does CO2 Laser Engraving Work on Metal?

CO2 lasers are often used for engraving metal. Laser engraving can be broken down into two categories: raster and vector engraving. Raster engraving refers to the process of creating a filled-in shape by scanning the laser across a large area to color it in. Vector engraving refers to the process of engraving only the outline of the shape.

What Can a CO2 Laser Engrave?

A CO2 laser can engrave a wide range of metals, glass, plastics, and organic materials like leather and wood. However, CO2 lasers do not produce good results on precious metals like gold and silver because they are highly reflective and don't have an adherent oxide layer. Highly reflective surfaces can cause eye damage as well as damage to the laser optics. In this case, the reflective surface must be coated with a non-reflective coating during engraving.

What Is the Spectrum of a CO2 Laser?

A CO2 laser has its spectrum within the mid-infrared range between 9,000-11,000 nm with the most common wavelengths being 9,600 nm and 10,600 nm.

CO2 lasers are able to have multiple wavelengths due to the fact that the CO2 is a triatomic molecule. A triatomic molecule means there are more potential energy levels to make use of.

What Are the Alternate Wavelengths for a CO2 Laser?

A CO2 laser can have a wavelength that can vary between 9,000-11,000 nm with the most common alternative wavelength being 9,300 nm. CO2 lasers cannot have real-time continuous wavelength changes as each discrete wavelength requires a specific tuning element within the gain medium to achieve a specific wavelength.

Why Is a CO2 Laser Used in Health Applications?

CO2 laser energy can be readily absorbed by water. This makes the CO2 laser ideal for health applications that require surgery on soft tissue. The moisture in living tissue absorbs the energy generated by the CO2 laser, causing controlled thermal damage in the tissue, known as "ablation ". This damage promotes the growth of healthy new tissue and promotes the formation of new collagen in skin treatment applications. CO2 lasers are also precise and fast-acting and can be used as an alternative to a scalpel to cut tissue.

What Is a CO2 Laser Treatment?

CO2 laser treatment refers to a range of medical procedures that make use of a CO2 laser. A CO2 laser is used because it is able to precisely apply thermal energy to vaporize or heat a small section of tissue. One common use of CO2 laser treatment is laser resurfacing. Laser resurfacing refers to the production of controlled skin tissue damage to promote the healing and regeneration of healthy, new skin.

What Are the Health Benefits of Using a CO2 Laser?

A CO2 laser can be used to apply thermal energy to a small, precise section of living tissue. The CO2 laser can cut, remove, or stimulate skin tissue, making it ideal for a range of skin treatments as listed below:

1. A CO2 Laser Helps Acne and Acne Scars

CO2 lasers are able to resurface skin that has been scarred by acne. During resurfacing, the CO2 laser damages the epidermis by vaporizing the affected tissue. This causes the reorganization of collagen during healing, which ultimately reduces the visibility of ice pick, boxcar, and rolling acne scars.

2. A CO2 Laser Helps for Stretch Marks

Stretch marks, also referred to as striae distensae, are a form of scarring caused by rapid body growth. This rapid growth causes tearing of the dermis, which ultimately results in the formation of scar tissue. Carbon dioxide laser resurfacing is used to damage the epidermis by vaporizing the affected tissue. The vaporizing of the tissue causes the collagen in the affected area to reorganize upon healing, which ultimately reduces the visibility of stretch marks. CO2 laser resurfacing also helps reduce the inflammation that is often present in these types of scars.

3. A CO2 Laser Helps Against Melasma

Melasma is a skin condition that most often presents itself as various shades of brown pigmentation on the forehead, lips, cheeks, and chins of people who are predisposed to the condition and are often exposed to sunlight. Fractional laser treatment is often required as the affected areas are far below the epidermis. It must be noted that laser treatment is considered a last resort after other topical treatments are explored as there is a chance that laser treatment can worsen the effect.

4. A CO2 Laser Helps with Scar Tissue (Scarring)

Scar tissue has many potential causes. The visibility of scars can be affected by the depth and type of injury that produced them. The main types of scars include:

- Contracture scars, which form after skin burns.

- Atrophic scars, which form as a result of acne or chicken pox.

- Keloid (or hypertrophic) scars, which are raised above the normal skin level and are caused by excessive healing after the injury.

5. A CO2 Laser Helps With Wrinkle Removal

Wrinkling can be caused by a number of factors, such as excessive exposure to sunlight, pollution, and the effects of aging. All of these result in reduced collagen production in the skin. As collagen production slows down, the skin becomes less elastic and firm and loses its ability to spring back into place after movement. This is why wrinkles form first near the mouth and eyes, which are in nearly constant motion. CO2 laser treatment for wrinkles uses the laser to damage the epidermis layer of the skin. During healing, collagen production is promoted, which firms up the skin and makes the skin elastic again, reducing the depth and visibility of wrinkles.

6. A CO2 Laser Promotes Uniform Skin Color

Skin color can lose its uniformity due to hyperpigmentation. This hyperpigmentation can be caused by: sun damage, scarring, fungal infections, melasma, and medications such as non-steroidal anti-inflammatory drugs (NSAIDS). Fractional CO2 laser treatment can be used to break down the melanin in deeper levels of the skin. Ablative CO2 laser treatment can be used to remove non-uniform colored areas and allow new skin to grow in its place.

7. A CO2 Laser Helps Treat Damaged Skin

Skin is damaged by a wide range of external and internal factors such as: aging, sun exposure, pollution, poor diet, scarring, stress, and body growth. CO2 laser resurfacing is a very effective method to treat most types of skin damage. Damaged areas are either removed with an ablative process allowing new skin to grow, or using less destructive fractional techniques are used to promote the regrowth of collagen.

8. A CO2 Laser Helps to Reverse Sun Damage on Skin

Extended exposure to the sun can cause significant damage to the skin including: wrinkles, discoloration, actinic cheilitis, and melanoma. CO2 laser resurfacing can treat a wide range of skin issues caused by sun damage. The most common technique is an ablative CO2 laser treatment which removes the top layer to allow for fresh new skin to grow.

9. A CO2 Laser Helps Treat Precancerous Skin Lesions

Precancerous skin lesions refer to several categories of skin conditions, such as: leukoplakia, actinic keratosis, Bowen disease, and actinic cheilitis. Dermatologists monitor precancerous lesions and often use CO2 lasers to remove them before they can progress to malignancy.

10. A CO2 Laser Helps Stimulate Collagen for Younger-Looking Skin

Fractional and ablative CO2 laser treatments both promote the regeneration and reorganization of collagen. CO2 lasers remove the epidermis and heat the dermis which promotes collagen growth. Increased collagen helps firm up wrinkled skin and therefore results in skin with a younger appearance.

What Are the Surgeries for Which a CO2 Laser Is Used?

CO2 lasers are used for a range of surgical applications, some of which are listed below:

- Laser Resurfacing: CO2 lasers are in wide service for the treatment of skin disorders using tissue ablation and fractional beam techniques. Typical applications include scar removal and collagen regeneration promotion.

- Incision and Excision: Lasers are often used to remove various types of growths such as warts, lesions, and nodules. CO2 lasers can also be employed as cutting tools in place of traditional scalpels. They produce precise cuts and also have a cauterizing effect caused by the heat of the beam that limits bleeding.

- Dentistry: CO2 lasers provide significant benefits in dental procedures, as they are able to treat both hard and soft tissues. For example, a CO2 laser was first used to ablate tooth enamel in 2009 and has since then become prevalent.

- Otolaryngology: “Otolaryngology” refers to the treatment of ear, nose, and throat conditions. The precision of the CO2 laser beam, coupled with its small size, makes a CO2 laser ideal for difficult-to-reach areas like the larynx. Airway lesions are easily treated with CO2 lasers.

Why Is a CO2 Laser Absorbed Better in Water?

The CO2 laser operates at a mid-infrared wavelength ranging from 9,300 to 10,600 nm. This range of wavelengths is readily absorbed by water.

Why Is Cellular Vaporization Prominent With the Use of a CO2 Laser in Health Applications?

Living tissue is largely made up of water, and CO2 lasers produce energy at a wavelength that is strongly absorbed by water. This means that when a laser is directed at the skin, most of the laser energy is converted to thermal energy. This heats up the water in the cells, vaporizing it. The volume expansion that occurs when water changes to steam destroy the tissue wherever the laser is targeted. This volume-expanding effect is very localized and reduces bleeding in the tissue surrounding the treated area due to the cauterizing action of the laser.

What Are the Industrial Uses of a CO2 Laser?

CO2 lasers are common in many industrial applications due to their ability to concentrate energy into a small area for cutting and welding a range of materials.

1. Laser Welding With a CO2 Laser

Laser welding makes use of a CO2 laser beam as the heat source that melts the weld joint and fuses the two metals together. The high targeting precision of a CO2 laser allows the welding of very small components without deforming the parts because of the excessive heat input that can result from moving conventional welding methods.

Lasers can also be used to weld thicker components by increasing the laser power and focal point energy density. CO2 laser welding is only used for specialized applications where its special advantages outweigh the high initial capital investment costs and the high ongoing maintenance compared to traditional welding techniques. CO2 laser welding can be used on common metals like carbon steel but is more often used to weld difficult materials like titanium and quartz.

2. Laser Cutting With a CO2 Laser

A CO2 laser cutter can produce laser beams with enough energy to cut through either thin sheet metal or thicker plates. High-pressure gas can be used to assist the cutting process. Lower-power lasers are used to cut other materials, such as plastic, wood, and paper. CO2 laser cutters are the most popular form of industrial laser cutter because they are highly efficient and easy to maintain compared to alternatives like fiber lasers.

For more information, see our guide on Laser Cutting.

What Are the Main Types of CO2 Laser Cutters?

The two main types of CO2 laser cutter technology are:

- DC (Direct Current) Laser: These are low-cost devices that make use of a replaceable glass laser beam generation tube design. The power output of these types of lasers diminishes over time, requiring operator adjustments to maintain a stable output.

- RF (Radio Frequency) Laser: RF lasers, also called ceramic lasers, are long-lasting, high-quality devices that maintain a consistent laser output power throughout their lifespans. RF lasers have higher-quality beams compared to DC lasers with high energy density.

Are CO2 Lasers Used in the Automotive Industry?

Yes, CO2 lasers are widely used for cutting and welding in the automotive industry due to their low cost, high speed, and energy efficiency. Typical uses include cutting interior fabrics, welding transmission components like gears, and welding body panels.

Are CO2 Lasers Used in the Aircraft Industry?

Yes, CO2 lasers are widely used in the aircraft industry due to their precision. Some applications include paint stripping and surface preparation for improved paint adhesion. Laser cutters are also used in aircraft construction to cut everything from textiles for interior trim to sheet metal panels and components.

Are CO2 Lasers Used in the Diamond Industry?

Yes, CO2 lasers are used in the diamond industry to cut, engrave, saw, shape, and block out diamonds. Diamonds can be laser-engraved for identification, helping to ensure that they were ethically sourced. Lasers can also engrave text inside the diamond, making it impossible to remove.

Are CO2 Lasers Used in the Textile Industry?

Yes, CO2 lasers are widely used in the apparel industry. CO2 lasers are a low-cost and efficient method for cutting clothing and accessory patterns as opposed to other methods, such as drag knives.

Are CO2 Lasers Used in the Woodworking Industry?

Yes, CO2 lasers are used in the woodworking industry to cut thin wooden boards, especially hardwoods, and to engrave artwork onto various types of wood. Lasers with powers less than 150 W are often used for woodworking applications to reduce the risk of burning the wood.

Does a CO2 Laser Cutter Have Two Tubes Filled With Gas?

Yes, a CO2 laser has two gas-filled tubes. The primary glass laser tube holds the CO2, N2, and He gas mixture. This tube is used to generate the laser beam. A helical tube is mounted inside this primary tube. A cooling gas circulates through the helical tube, transferring heat away from the primary laser tube to keep it at an optimum temperature. In some cases, the cooling fluid may be a liquid instead of a gas.

Does a CO2 Laser Cutter Work by Melting the Surface With a Laser Beam?

Yes, a CO2 laser cutter works by melting the surface of the material to be cut with a laser beam. However, this is just one part of the process. After the laser beam melts the surface of a material, a compressed gas, such as nitrogen, can assist in continuously blowing the molten material out of the cut path. Alternatively, an oxygen jet can be used to create an exothermic reaction where the laser hits the material, actually helping to melt it faster and then eject the melted droplets from the site. This process can provide more energy to help cut thicker and difficult-to-cut materials.

What Materials Are CO2 Laser Cutters Used With?

A CO2 laser can cut a variety of different materials. For that reason, it is an excellent general-purpose cutting tool. Some typical materials that can be cut with a CO2 laser are listed below:

- Wood

- Hardboard

- Foam

- Felt

- Brass

- Leather

- Aluminum

- Rubber

- Paper

- Plastic

- Carbon steel

- Cork

- Carbon fiber

- Fabric

- Stainless steel

What Is the Difference Between a CO2 Laser and a Fiber Laser?

A CO2 laser makes use of a tube filled with CO2, N2, and He gas molecules. A strong electric field energizes the nitrogen gas molecules, which then transfer their energy to the CO2 molecules. This causes the electrons in the CO2 gas molecules to attain a higher energy level. Eventually, the energized electrons fall back into a stable state and emit photons. These photons then cause other nearby CO2 molecules to also emit photons, creating a photon cascade. The photons then bounce between mirrors at either end of their containment tube, gaining energy on each pass. At a certain point, they have enough energy to pass through a semi-reflective mirror and are then directed to the focusing heat via a range of mirrors.

A fiber laser, on the other hand, is a solid-state laser. Instead of a gas-filled tube for generating the coherent light of the laser beam, it has a fiber optic filament with one section that is doped with neodymium atoms. Light is pumped into this filament. Once it reaches the doped section, the photons in the light waves excite the electrons in the neodymium atoms, which release other photons with a very specific wavelength. These photons then pass near other excited neodymium atoms which causes the excited electrons to drop down into a stable state, thereby emitting new photons causing a cascade effect. Fiber lasers make use of a device called Bragg grating, which has the same function as the two mirrors in a CO2 laser. The laser light reflects back and forth along the filament until it reaches the specific energy level required for it to pass through the grating as a coherent beam of light. This beam then travels down the length of the filament until it reaches a focusing mirror.

For more information, see our guide on CO2 Laser vs. Fiber Laser.

Summary

This article presented CO2 lasers, explained what they are, and discussed their history and benefits. To learn more about CO2 lasers, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including sheet and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.