What Is Sheet Metal Bending?

Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the final geometry. The thickness of sheet metal used can vary. The minimum thickness sheet metal can be bent is approximately 127 mm thick and the maximum will depend on the material type and thickness. Generally, sheet steel is no more than 6 mm thick. As a rule, the bend radius should be equal to or greater than the thickness of the material.

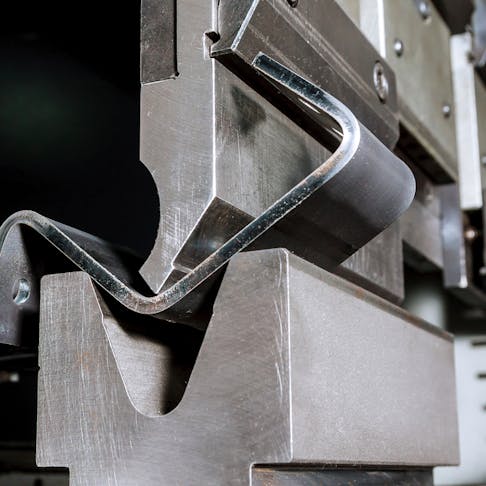

Sheet metal bending is also known as forming, edging, folding, flanging, press braking, or die bending. The last of the names is used as some sheet metal bending is achieved using a die and punch system. Press braking refers to cases in which a press brake machine is used to bend the sheet metal.

Industries That Use Sheet Metal Bending

The use of sheet metal bending is widespread, including: in the construction, automotive, transport, aerospace, and infrastructure industries. Sheet metal bending can be used in every industry to create features such as lips, joggles, flanges, and indents. Sometimes sheet metal bending is used to increase the stiffness of a sheet metal part.

How Sheet Metal Bending Works

Sheet metal bending with a press brake works by aligning and holding the metal to be bent in the press brake tool. Once it is aligned, the press can move down and exert a force onto the metal, forming it into a new shape by producing angles. Press brakes can exert forces well in excess of 100 tons to bend steel upwards of 3 mm thick.

There are a few different kinds of machines that can be used to bend sheet metal. The most common is a press brake machine which itself can be mechanical and fully manual (usually used in small machine shops), or it can be computer numerically controlled (CNC) and uses a hydraulic system. The principles used in both machines are the same, but the way the operator interacts is different. This process below will focus on the operation of a CNC press brake machine:

1. Calculate the Design Parameters

Before using the press brake, calculate the design parameters including force required, bend line (the point where the force is exerted), and the order of bends (if there are multiple). The die used to create the bends must also be decided.

2. Set Up the Press Brake

To set up the press brake, input the information calculated into the CNC machine, so it knows how much force to exert on the metal to create the right bend and in which order these bends will be carried out. The right tool and die must be attached to the press and brake, ready for bending.

3. Align the Part

Align the metal between the tool and die. When the machine is operated, it will bend the sheet of metal at the bend line.

4. Engage the Press Brake

Engage the press brake so that the force parameters—inputted into the CNC press brake at step 2—are applied. Once the press brake has bent the metal, the part can be removed and made ready for the next stage of production.

Metals Used in Sheet Metal Bending

There are a range of metals that can be used in sheet metal bending. Six metals are discussed below:

1. Steel

Steel is a very versatile metal that consists of iron and carbon. Steel is economical and has great strength and durability. There are a range of different steels that can be bent including mild steel and stainless steel. Mild steel is easily bent and used widely, including in a range of automotive applications.

2. Aluminum

Aluminum is a lightweight and cost-effective metal used in the aerospace, electronics, and automotive industries. Aluminum is easy to fabricate and benefits from a high strength-to-weight ratio and high corrosion resistance.

3. Copper

Copper is a soft metal that allows it to be easily bent and formed. It is also highly conductive, making it perfect for electrical applications. Copper is also naturally antimicrobial and recyclable.

4. Brass

Brass is an alloy consisting of zinc and copper. Brass is used a lot in sheet metal bending because of its aesthetic appeal and ease of fabrication. Because of its aesthetic appeal, it is used in decorative applications including: home hardware, architecture, and instruments. Brass benefits from high machinability, low friction, and corrosion resistance.

5. Stainless Steel

Stainless steel, like regular mild steel, is made of iron and carbon, but with the addition of chromium and nickel. Due to the extra chromium and nickel, stainless steel is also harder and work hardens as it bends. This means that stainless steel usually requires a press brake rather than bending by hand. Stainless steel, which uses chromium to protect against degradation, is used in medical and food processing equipment.

6. Galvanized Steel

Galvanized steel, like stainless steel, is highly corrosion-resistant. This is because galvanized steel has a zinc coating. In addition to having an improved service life, galvanized steel components are lower cost than other forms of corrosion-protected steel.

How Xometry Can Help

Xometry has a wide range of sheet metal bending capabilities. We work with the most commonly requested materials and can accommodate custom requests. We can also provide welding and assembly services, providing you with a complete solution for your sheet metal fabrication needs. Best of all, you can get an instant quote for bent sheet metal parts by visiting the Xometry Instant Quoting Engine® and uploading your 3D CAD today!

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.