Laser diodes are a diverse family of electrically pumped semiconductor lasers. They differ in operational and construction details and cover a wide range of emission frequencies and powers, but they have many areas of core technology in common. All semiconductor lasers generate light in the active region, which forms at the p-n junction where electrons and holes recombine under forward bias. When a forward-biased electrical current is applied (+ve to the p and -ve to the n) to the diode, “electrons and holes” are driven to the junction regions and they cancel when they meet, releasing a photon through spontaneous emission, which then initiates further stimulated emission. The photons then generally undergo multiple reflections within the diode cavity, amplifying the light through optical gain in a complex, many-bodied interaction between photons, holes, and electrons.

Listed below are the 15 different types of diode lasers:

1. Edge-Emitting Diode Lasers

Edge-emitting diode lasers emit laser light from the edge of the semiconductor chip. They emit light parallel to the chip surface. Edge-emitting diode lasers are formed from a chip made of gallium arsenide (GaAs), indium phosphide (InP), or gallium nitride (GaN). The chip is composed of two (or more) layers, including the charge depletion (active) region at the p-n junction, where the laser effect occurs.

Edge-emitting diodes can provide high optical power levels, ranging from milliwatts to ten watts or more. They also offer high electrical efficiency, particularly in medium- to high-power applications, compared to many other laser types. These lasers are used in most fields: telecommunications, optical data storage, barcode scanning, laser printing, optical sensing, medical equipment, and industrial laser systems.

2. Vertical-Cavity Surface-Emitting Lasers (VCSELs)

Vertical-cavity surface-emitting lasers (VCSELs) are a class of semiconductor lasers that emit light perpendicular to the chip surface. VCSELs are formed from a p-n junction chip with a vertical cavity, consisting of two distributed Bragg reflector mirrors. The active region, where electrons and holes recombine to emit photons, is centered between these mirrors. This laser type generally populates the active region with quantum wells or similar gain-inducing structures. The light is emitted perpendicular to the surface of the chip as a circular or elliptical beam with a well-defined and symmetrical profile. This beam profile responds well to collimation, with relatively low divergence.

These devices have several advantages over edge-emitting diode lasers. Their threshold current is low, allowing high electrical efficiency at low power levels. Those devices with a circular beam profile are well suited to coupling to optical fibers. A major advantage of VCSELs is that they can be manufactured at wafer scale, resulting in lower production costs and higher uniformity than individually constructed devices.

VCSELs are available to emit wavelengths primarily in the near-infrared and visible ranges, though some research prototypes extend toward the mid-infrared. The wavelength of the output results from material selection, junction design, and resonant cavity form. They are widely used in fiber-optic networks, optical interconnects, and high-speed data transmission systems. They are also used in 3D sensing for facial recognition and depth sensing in mobile devices, and in more general optical and sensing applications such as optical mice, laser printers, and 3D scanners.

3. Distributed Feedback (DFB) Lasers

DFB (distributed feedback) lasers have a similar structure to other semiconductor lasers. However, the inclusion of a periodic grating structure within the active region, or the external waveguide, is unique to this class. The distributed feedback grating consists of a periodic variation in the refractive index of the waveguide region, which provides wavelength-selective optical feedback, not a modulation of the gain profile. This acts as a feedback mechanism, forcing optical feedback/amplification at a selected wavelength while suppressing other modes. This means these devices produce light at a specific wavelength with high spectral purity and narrow linewidth. This is ideal for high-data-rate fiber-optic communications, sensing, and various high-resolution spectroscopy and metrology applications.

DFB lasers can also be tuned over a limited wavelength range by adjusting temperature or injection current, which changes the refractive index and thus the Bragg condition. They typically do not use external feedback mechanisms.

4. Quantum Cascade Lasers (QCLs)

The quantum cascade laser (QCL) uses quantum cascade transitions between energy levels within multiple semiconductor junctions as the laser source. QCLs are constructed from multiple quantum wells, with barriers formed by semiconductor layers of various bandgaps. When a forward bias current is applied, only electrons travel through a cascade of quantized energy levels, emitting photons at each intersubband transition without involving holes. They provide emission in the mid-infrared and terahertz regions of the electromagnetic spectrum and can emit a broad range of wavelengths within these regions. While many mid-infrared laser technologies require cryogenic cooling, modern QCLs can operate at or near room temperature, depending on design and heat management. Delivering high optical power levels makes them suitable for higher-energy applications, delivering continuous-wave (CW) mode with very stable output.

Relatively simple tuning of the emission wavelength is achieved by adjusting layer thicknesses and the bias voltage, making them ideal for spectroscopic analysis applications requiring multiple wavelengths. They are also used for environmental monitoring, medical diagnostic systems, remote sensing, and free-space communication.

5. External Cavity Diode Lasers (ECDLs)

ECDLs are a format of device that utilizes an external cavity, typically incorporating a diffraction grating or mirror, to provide wavelength-selective optical feedback and control the laser's emission characteristics. ECDLs allow increased tunability, narrow linewidth, and precise wavelength control compared to other formats of the diode laser. They have a similar structure to other diode lasers, with a forward-biased p-n junction and an active region in which photons are emitted. The external cavity provides wavelength-selective optical feedback, enabling precise tuning of the emission frequency and linewidth control. This cavity houses a reflector, grating, or other optical structure that reflects a proportion of the beam back into the cavity.

ECDLs can facilitate narrower line widths, in comparison to other diode laser types. The external cavity suppresses unwanted longitudinal modes and optical noise, delivering better coherence and a narrower linewidth beam. This class of device is ideal for applications requiring high spectral purity for very precise optical quantization.

ECDLs deliver significantly improved wavelength tunability compared to most diode lasers. The laser wavelength can be precisely tuned by subtly adjusting the position or incident angle of the external reflector or grating. This allows for a wide spectrum of demanding applications in spectroscopy, atomic and molecular physics, and metrology. With precise design, ECDLs can achieve mode-hop-free tuning across a limited wavelength range, allowing smooth frequency adjustments without sudden jumps between modes.

6. Tapered Diode Lasers

Tapered diode lasers (or tapered amplifiers; tapered lasers) are a class of lasers with a tapered amplification cavity. These lasers achieve high power output, good beam quality, and high electrical efficiency. This tapered region is narrow at the input end (near the ridge waveguide) and gradually widens toward the output end. This tapering serves to increase the beam width and reduce the optical density in the laser amplification region.

The tapered amplification section allows for increased mode area, enabling higher optical power extraction. It also helps to improve beam quality and makes the output more amenable to collimation. The taper allows for better management of optical intensity, reducing nonlinear effects and damage risk while supporting higher output power. Another benefit of the taper is to increase the gain spectrum, allowing for a wider range of wavelengths in the output. This tunability is a particularly valuable feature of the class. These devices are widely used in material processing, laser engraving, and laser pumping (for high-power gas and solid-state lasers). Their high power and good beam quality make them suited to demanding applications in which precision, speed, and power are essential.

7. Superluminescent Diode (SLD) Lasers

SLDs (superluminescent diodes), also known as amplified spontaneous emission (ASE) sources, are not considered true lasers because they lack optical feedback and do not achieve lasing through stimulated emission in a resonant cavity. They combine features of laser diodes and LEDs to emit high-power, broadband light without optical feedback. They produce wide-spectrum light of high intensity, rendering them suitable for particular applications in imaging, fiber-optic sensing, and telecoms. SLDs generate partially coherent light through amplified spontaneous emission, without feedback-induced lasing. These devices produce a wide bandwidth of light, ranging from tens to hundreds of nanometers, making SLDs suited to applications that require a wide spectral range or high-resolution imaging. SLDs deliver high radiance, meaning high optical power per unit area, solid angle, and bandwidth—greater than LEDs but less than true lasers. The high brightness results from amplified spontaneous emission and optical amplification. Their output has a short coherence length compared with conventional lasers. This is the distance over which the electromagnetic waves maintain their phase relationship. This makes them suitable for applications that require low-coherence interference or depth-resolved imaging. SLDs are used in optical coherence tomography (OCT), fiber-optic sensing, spectroscopy, biomedical imaging, optical metrology, and optical testing. In OCT systems, they enable high-resolution imaging of biological tissues and materials.

8. Double Heterostructure Lasers

Double heterostructure (DH) lasers are a type of diode laser that use a layered semiconductor structure to enhance carrier and optical confinement, improving performance. DH lasers have lower threshold current, higher efficiency, and increased output power, in comparison to the common homojunction construction.

DH lasers are constructed with a narrow-bandgap active region sandwiched between two wider-bandgap cladding layers of opposite doping types (one p-type and one n-type). This configuration creates efficient confinement of the carriers and a leak-free optical mode, increasing electrical efficiency and overall performance. Increased carrier confinement helps to increase carrier density and recombination, leading to higher gain and improved operational efficiency in most aspects. The heterostructure also enhances optical confinement by creating a refractive index step, guiding the light within the active region, and increasing light-matter interaction. The lower threshold current results from lower charge-carrier leakage, enabling the laser to reach the threshold for the onset of lasing at lower current levels.

Applications include telecoms, laser printing, optical data systems, and precision measurement tools. They are particularly valuable in long-distance fiber-optic communications, where high efficiency, low threshold currents, and high output are beneficial.

9. Quantum Well Diode Lasers

Quantum well diode lasers are a family of devices that contain quantum well structures, which enhance optical and electrical properties. They achieve lower threshold current, a higher power efficiency, and improved wavelength control, relative to more basic devices. These devices are constructed from a layered structure of thin semiconductor wafers of narrower bandgap, encased in higher bandgap layers. The quantum well layer creates a confinement region for both carriers and generated photons, improving optical amplification. Carrier confinement in the quantum well region increases the probability of radiative recombination, enhancing stimulated emission and improving power conversion efficiency. They allow precise control over the generated wavelength by adjusting the well width and composition. This allows the emission wavelength to be tuned precisely to demanding specifications.

Quantum well diode lasers can exhibit narrow linewidth output, especially when configured in single-mode designs. Suppressing mode competition and optical noise enhances coherence and spectral purity. Quantum well lasers are commonly applied in data storage, diagnostics, telecom, and printing due to their efficiency and precision. Compact and efficient sources of radiation for fiber-optic communications are critical in high bandwidth and long-distance fiber optics.

10. Single Longitudinal Mode Laser (SLM) Lasers

Single longitudinal mode (SLM) lasers emit a single frequency or wavelength with high coherence and narrow linewidth. They achieve this using mode selection elements, frequency stabilization, and optimized cavity design. By suppressing competing longitudinal modes, SLMs produce a highly coherent beam with a tightly defined frequency.

SLM lasers support applications in metrology, spectroscopy, interferometry, fiber sensing, and telecoms, particularly in research settings.

11. Interband Cascade Lasers

Interband cascade lasers (ICLs) generate laser light using transitions between energy bands in the active region. The device architecture cascades interband transitions across multiple stages, each with its own quantum wells and active region, enhancing optical gain per injected carrier. ICLs operate efficiently in the mid-infrared spectrum and offer high performance for sensing and spectroscopy applications. Conventional diode lasers rely on interband transitions in a single junction, while ICLs use interband transitions across multiple cascaded stages. ICLs are commonly designed to emit in the mid-infrared range, typically between 3 and 6 micrometers, though extended designs may reach up to ~12 micrometers. Multiple quantum well stages are electrically connected in a cascaded configuration. Each stage participates in the gain process, resulting in higher optical amplification than single junction devices.

ICLs deliver a particularly low threshold current for the onset of lasing. Higher efficiency carrier transport and utilization result in lower power consumption. ICLs are applied to gas sensing, chemical analysis, environmental monitoring, industrial process control, and free-space optical communications. Mid-infrared radiation is useful for detecting and measuring specific pollutants.

12. Separate Confinement Heterostructure Lasers

Separate confinement heterostructure (SCH) lasers use a heterostructure design to improve optical and electrical properties. This delivers reduced optical losses, enhanced carrier confinement, and improved overall performance compared with common homojunction lasers. SCH lasers incorporate several wafers with varying band gaps to form a more complex heterostructure. The active region, where lasing occurs, is sandwiched between layers of wider bandgap materials that provide both electrical and optical confinement. This complexity allows for enhanced confinement of both carriers and optical modes.

Cladding layers provide optical confinement by creating a refractive index contrast, while carrier confinement is achieved through bandgap engineering that restricts carrier diffusion out of the active region. Reduced carrier leakage particularly contributes to improved threshold current and electrical efficiency. In turn, this enhances performance, compared to homojunction lasers, by improving temperature stability, higher modulation bandwidth, and temperature-dependent wavelength drift. SCH lasers are particularly useful in applications requiring efficiency and temperature stability. They are suited to general applications like telecoms, optical data storage, laser printing, optical sensing, and laser-based research, but they are particularly suited to harsher environments and fiber-optic communications systems.

13. Distributed Bragg Reflector (DBR) Lasers

Distributed Bragg reflector (DBR) lasers incorporate Bragg reflectors positioned outside the active gain region, forming part of the resonator cavity but not distributed within it. This aspect allows precise control of emitted frequency and narrow filtration for good spectral purity and selection. The Bragg grating consists of a periodic variation in the refractive index along a waveguide, acting as a wavelength-selective mirror by constructive interference at the Bragg condition. This structure reflects light of all non-selected wavelengths, allowing the desired radiation to propagate through the amplification cavity. This structure provides precise wavelength selectivity. In tunable DBR lasers, the emitted wavelength can be adjusted by changing the grating period (during fabrication) or by thermally tuning the refractive index. This facilitates customization and compatibility with a range of applications, including wavelength-division multiplexing (WDM) systems and optical coherence tomography (OCT).

DBR lasers provide narrow linewidth output as a result of the distributed feedback of the Bragg grating. The grating suppresses undesirable longitudinal modes and results in a single-mode emission of narrow spectral width. These devices deliver beneficial, high side-mode suppression ratios (HSMSR), representing the power difference between the desired laser mode and the neighboring modes, providing a measure of selectivity, spectral purity, and narrow linewidth.

Common applications include telecoms, fiber-optic sensing, spectroscopy, metrology, and OCT. They are used as precise and stable light sources in various systems that require specific wavelengths, narrow line widths, and high spectral purity.

14. Vertical-External-Cavity Surface-Emitting Lasers

Vertical-external-cavity surface-emitting lasers (VECSELs) are semiconductor lasers that extend the VCSEL concept by incorporating a partially external cavity, allowing enhanced power scalability and wavelength tunability. This results in unique features such as high output power, wavelength tunability, and excellent beam quality.

VECSELs emit light perpendicular to the semiconductor wafer surface, with a gain region designed for vertical emission and an external mirror forming part of the laser resonator. This architecture enables efficient heat removal and excellent beam control. Their external cavity configuration is constructed from additional reflective surfaces placed outside the chip structure. This enables wavelength control, beam shaping, and power scaling. VECSELs are capable of higher output power than VCSELs because the external cavity configuration improves heat dissipation. Wavelength tunability is achieved by adjusting the position or angle of the external mirror, using intracavity elements such as etalons, or by controlling temperature to shift the gain peak. Through precision-designed external cavity use, VECSELs achieve a high-quality output of low divergence angle and uniform beam profile.

This laser type finds utility in fields such as research, diagnostics, sensing, and telecommunications. They serve precision applications like laser spectroscopy, laser cooling and trapping/manipulation of atoms, laser ablation, and high-data-rate optical communications.

15. Multi-Longitudinal Mode (MLM) Lasers

Lasers operating in a multi-longitudinal mode (MLM) regime emit several closely spaced longitudinal modes simultaneously, producing a broadened spectral output. The longitudinal modes in MLM lasers are narrowly spaced. The spacing depends on the functional design of the resonant cavity, such as its length and the refractive index of the laser medium. Their broad emission spectrum is due to the presence of these multiple modes. The spectral width and distribution of the modes arise because of the cavity and junction design, and also from the operating conditions.

MLM lasers are used in spectroscopy, metrology, interferometry, and telecoms. While multi-longitudinal mode lasers can be used in interferometric techniques, OCT systems more commonly employ broadband low-coherence sources such as superluminescent diodes (SLDs) for optimal axial resolution.

The variety of diode laser types allows engineers to fine-tune performance for almost any application. From broadband sources for imaging to narrow-linewidth lasers for sensing, choosing the right architecture is often the key to balancing power, precision, and integration.

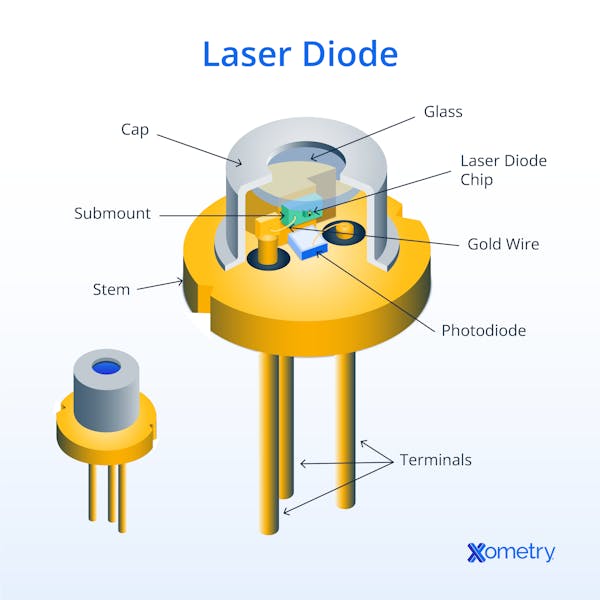

What Is a Diode Laser?

A diode laser is a semiconductor device that emits coherent or nearly coherent light, often monochromatic, through the process of stimulated emission. Its operational principle involves the emission of a photon for each charge cancellation in the depletion region at a p-n junction. Some diode lasers, such as multimode or superluminescent types, emit light across multiple longitudinal modes or broader spectral bands, rather than a single pure wavelength. They vary in beam forming, beam quality, coherence, and linewidth, due to a range of design formats and material choices.

For more information, see our How Does a Laser Diode Work guide.

How Does a Diode Laser Work?

In the simplest type, a forward-biased p-n junction drives electrons and holes into the active region, where they recombine and emit photons. At each hole/charge meeting, a coherent and specific-frequency photon is emitted. Photons are confined within a resonant optical cavity formed by reflective facets, allowing repeated stimulated emissions and amplification.

How Important Are Diode Lasers?

Diode lasers have a huge range of medical, scientific, industrial, and consumer-product applications, and they are a cornerstone component family within a surprising range of technologies. This results from their versatility, compact size, efficiency, direct current operation, wavelength range, cost-effectiveness, and reliability. The importance of diode lasers is evident from their widespread adoption across industries and the broad range of applications they serve.

What Is the Primary Use of a Diode Laser?

One of the most widespread uses of diode lasers is in optical data transmission for telecommunications and internet infrastructure. Diode lasers are key to fiber-optic communication systems to transmit data over long distances with high bandwidth. This results from their best-in-class functions such as:

- High-data-rate capability

- Compact package size

- Electrical efficiency

- Wavelength compatibility

- Direct modulation capability

- Long operational life span/reliability

What Are Some Applications of Laser Diodes?

Laser diodes are heavily employed across many fields, including:

- Printing

- Engraving and marking

- Cutting

- Fiber-optical communication

- Medical and aesthetic treatments

- Optical data storage

- Barcode scanning

- Sensing and metrology

- Display and projection of images

- Spectroscopy and chromatography

- Scientific research

How To Choose the Type of Laser for Your Need?

Choosing the right type of laser for your specific needs requires considering several key factors, such as:

- Application: Understanding your application requirements will help narrow down the suitable laser types.

- Output Power and Input Energy Requirements: Some applications may require high-power lasers for tasks like cutting thick materials, while others may require low-power lasers for precision tasks such as engraving, and still others may require electrical power efficiency for portable applications.

- Wavelength: The choice of wavelength depends on the details of the application, such as the material to be processed, absorption characteristics, data rate, transmission characteristics, etc.

- Beam Quality: Some applications may require high-quality and excellent collimation, whereas others may be less sensitive to beam quality than device cost.

- Reliability and Maintenance: If low maintenance is a requirement, diode laser sources are ideal, but differences across the class might influence selection.

- Cost: Where cost is a determining factor, device simplicity is usually beneficial. Remember, cost includes not just the device price, but also long-term ownership expenses like maintenance, energy consumption, and reliability.

How Can Diode Lasers Be Used in Laser Cutting?

Diode lasers can cut thin wood, plastics, leather, or soft materials, but are generally unsuitable for thick metals without specialized setups. The use of diode lasers of all types is increasing in cutting applications. Frequency selection, linewidth, beam quality (of some laser diode types), power efficiency, compact size, and particularly device life/maintenance benefits are critical factors. For more information, see our How Does Laser Cutting Work guide.

Can Diode Lasers Be Used for Laser Welding?

Yes, diode lasers are suited to some laser welding applications, particularly where their characteristics align with the requirements of the process. These are some advantages diode lasers offer in welding applications:

- Diode lasers have fast modulation and switching capabilities. This provides for rapid on/off switching for tight control and rapid processing of complex welds.

- Moderate penetration is possible in certain materials. While diode lasers can achieve deep welds in plastics and some metals, fiber or disk lasers are generally preferred for deeper or high-strength welds.

- Joining dissimilar materials by providing a concentrated and localized heat source allows for controlled and precise distribution of heat into materials with different thermal characteristics.

- Compact welding devices result from high energy density in the laser and limited need for ancillary devices such as cooling systems.

- They are cost-effective compared to other laser types like fiber lasers or solid-state lasers.

Is It Possible To Use Diode Lasers for Engraving?

Yes, diode lasers can be used for engraving, particularly for applications that require precision and low-power engraving. While diode lasers may not be as commonly used as fiber lasers or CO2 lasers for industrial engraving on a wide range of materials, they can still be effective in certain scenarios.

Summary

This article presented 15 different types of diode lasers, explained them, and discussed how each are used. To learn more about diode lasers, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.