Did you know that we offer different finishes for SLS 3D printing? Check out the guide below to learn about the various finishing options we offer.

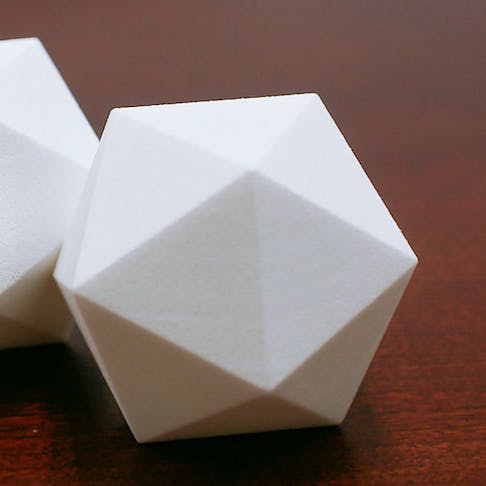

This is the default finish for SLS. Parts are removed from the build chamber and all powder is cleaned through bead blasting. The surface appearance is a satin-like matte finish that is slightly grainy to the touch.

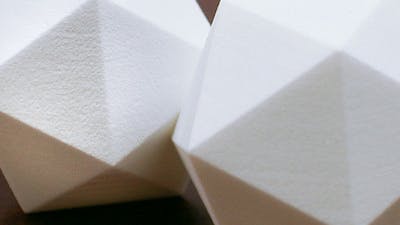

Parts are tumbled in polishing media for several hours to smooth outer surfaces. The resulting finish is smooth to the touch with a satin-like matte appearance.

Note: Sharp edges may be dulled during this process and parts with fragile features are not recommended for tumbling.

Colors are applied to parts with a standard finish using dye. This process is currently available in red, yellow, blue, green, and black.

Note: The dye penetrates 0.25mm into the part surface.

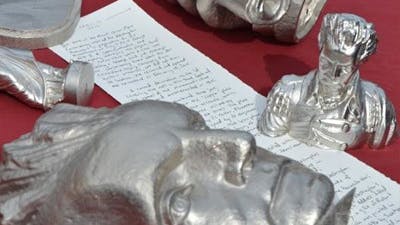

Parts are plated with ~0.1mm / 0.004″ nickel. Plating increases part strength, stiffness, and environmental resistance.

Note: This finishing process adds 4-5 business days to the lead time.