Metal Extrusion Services

High Quality, Low Cost Metal Extrusions With Xometry.

The Extrusion Process

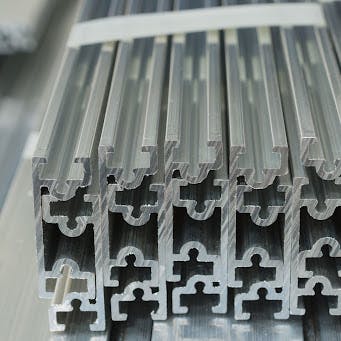

Metal extrusion is the manufacturing process of choice when producing high volumes of material with a constant cross-section. With the extrusion process, metal material is forced through the shaped opening of a die using high pressure, resulting in an extruded profile. These profiles range from simple shapes like round or rectangular tubes, U- or H-channels, or more complex profiles with multiple internal hollows and external features, such as 80/20 and T-slot framing bar. Extrusion is also standard for wall and window trim as a cosmetic and structural framing component. The raw material typically comes in billet form, which is heated and placed into part of the extrusion press called the container. A die stack sits on the other end of the container, forming the opening, which shapes the material to the desired shape using direct or indirect extrusion methods. The extrusion is then quenched, straightened, sawed to the specified length, and inspected for dimensional consistency and accuracy. Extruded products can easily be post-processed to add features outside the channeled profile.

The extrusion profile can be almost any shape and be either solid or hollow with one or more hollow sections. Extrusions with hollow sections require a multi-part die. The material is forced around piercing mandrels supported in the first die, forming the inner profile. The material separates and then is forced or “welded” back together by the second die, creating the outer profile. The smallest circle that will fit around the profile determines the press size. The larger the circumscribed circle, the larger the extrusion press required. Xometry specializes in extruding aluminum materials, representing roughly 80% of all extruded metal parts. Aluminum extrusions are everywhere, from window casings to handrails to electrical housings.

Our project managers and experts personally review and manually quote each metal extrusion project to ensure we meet your unique needs while providing a fast and easy manufacturing experience. Learn more about the process and our capabilities in the sections below.

Metal Extrusion With Xometry

Start A Quote

Upload your files to the Xometry Quote Engine and configure your project. Our team will consult with you to ensure your specifications, lead time, and price fit your project needs. We will provide a DFM report for approval before kicking off tooling.

Sample Approval

Once your project is kicked off we will build a high-quality metal extrusion die. After the tooling is created we will run and send out part samples for approval.

Production Begins

Once you're satisfied with your samples, we move forward with production and deliver the parts. Rest easy knowing Xometry is handling supplier management and logistics throughout the process. You own your tooling and can easily re-order as needed to meet demand.

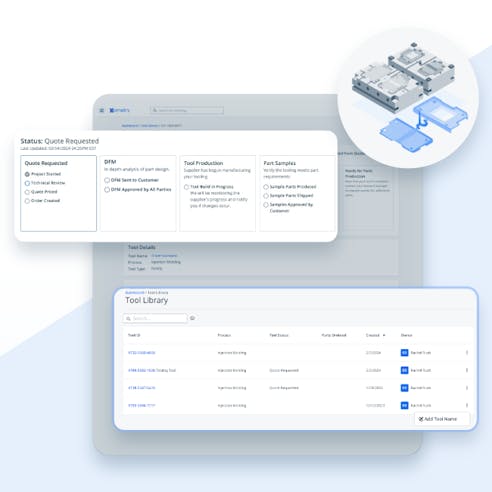

Built-In Tool Management

Xometry's platform has built-in features that make managing tooled projects a breeze, giving customers greater transparency into production. Find all your tooling quotes and orders in one space with your Tool Library. From there, you can explore their Tool Details page, which covers the current status, milestones, tool specifics, and activity related to that tool. You can also easily find and contact the Xometry team member assigned to your project, no matter the project's current phase.

Our Tool Library and Tool Details pages provide multiple benefits, such as:

- Better Management of Tooled Quotes & Orders

- Tool Organization & Categorization

- Detailed Status Updates & Tooling Information

- Easily Connect with Experts

- Project Transparency

Types of Extrusion and Extrusion Profiles

Xometry partners with the leading extrusion suppliers who utilize the most sophisticated technology to deliver high-quality extrusions. Thanks to our manufacturing network, we can support multiple types of metal extrusion and an endless array of extrusion profiles. The sections below dive deeper into the different extrusion methods and provide examples of standard extrusion profiles.

Types of Extrusion

Direct Extrusion

Direct extrusion, also referred to as forward extrusion, is the most common metal extrusion method. With this type of extrusion, a billet of material is pushed through a container by a high-pressure ram. The material flows in the direction of the ram motion and exits through the opening of the stationary die. Direct extrusion allows for larger profile designs and a higher quality surface finish than the indirect extrusion method.

There are some disadvantages to consider with this method. A large amount of friction generates between the material and the walls of the container, which results in decreased die face pressure and temperature variances. These factors make it more challenging to control dimensional consistency and the material’s properties.

Indirect Extrusion

With indirect extrusion, the material is placed into a container and secured. The extrusion die moves with a hollow ram over the material, forcing it through the die opening. Indirect extrusion is also sometimes referred to as backward extrusion because the material flows in the opposite direction of the ram motion. Since there is no relative movement between the material and container, there is much less friction with this method, resulting in lower energy use and less heat generation. With less heat, indirect extrusion generally has greater control over dimensional consistency, material properties, and grain size when compared with direct extrusion.

However, the drawback to this type of extrusion is a more significant limitation on overall die profile size, as it must fit inside the hollow ram. The billet’s surface impurities can find their way into the extruded product reducing the overall surface finish and aesthetics.

Hot, Warm, and Cold Extrusion

These are sub-categories of extrusion integrated into the primary methods discussed above. The temperature of the billet relative to the room and material recrystallization temperature defines hot, warm, or cold extrusion. Hot extrusion is when the billet is heated well above the material’s recrystallization temperature, often associated with the direct extrusion method. The heating of the material softens it and prevents work hardening, so it more easily flows through the die, reducing wear on the tooling. Warm extrusion is when the material is heated above room temperature but remains well below the recrystallization point. The material is not heated in cold extrusion and remains at room temperature.

Warm and cold extrusion can increase the hardness and strength of the extruded product due to no excessive raw material heating. These processes work best with high ductility materials, such as aluminum. The warm and cold processes are typical of the indirect metal extrusion method. While not drastically heating the material can provide benefits, it can be harder on the tooling and reduce the lifetime of the die. With this in mind, most manufacturers opt for hot extrusion methods.

Extrusion Profiles

Extrusion profiles represent the cross-sectional shape that forms the extruded product. Xometrys custom manufacturing services enable you to get extruded parts made with custom extrusion profiles. If you are looking to save cost and time by post-machining an existing aluminum extrusion profile, we can do that too! Below is a list of some off-the-shelf aluminum extrusion profiles we can modify via another manufacturing process, such as our CNC machining service.

- T Slot Aluminum Extrusions

- Aluminum Angles

- T-Bars, H-Bars, Z-Bars

- I-Beams

- U-Channels

- Hat Channels

- Rectangular Tubes

- Round Tubes and Pipe

Aluminum Extrusions

Extruded aluminum makes up roughly 80% of all extruded metal products due to its versatility across industries, mechanical properties, diverse finishing options, and high ductility, making it ideal for extrusion processes. Most extruded aluminum alloys are lightweight, resistant to corrosion, and have high thermal and electrical conductivity. Some aspects of each alloy set it apart from the others. To help you choose the right one for your project, we have compiled a table below of the most commonly used alloys we offer and their unique characteristics.

If your project requires stainless steel or other metal extrusions, we have a “custom material” option within our quoting interface. This option enables you to submit custom requests which we will be happy to review and explore further with you.

Extruded Aluminum Alloys Comparison Table

| Alloy Name | Description | Characteristics | Suitable Applications |

|---|---|---|---|

Alloy Name 6061 | Description 6061 is a versatile alloy that can be heat-treated to tempers such as 6061-T6. Magnesium and silicone are primary alloying elements that give the material high structural strength, toughness, and weldability. | Characteristics

| Suitable Applications Transportation components for automotive and marine environments |

Alloy Name 6063 | Description 6063-T5 is a very economical heat treatable alloy with a smaller grain structure than 6061 alloys. 6063 is more common for extrusions than 6061. It can form parts with thin walls and responds well to finishing processes, making it suitable for decorative applications. | Characteristics

| Suitable Applications Decorative trim, heat sinks, architectural components |

* Typical minimum representative values ; material temper may affect mechanical properties

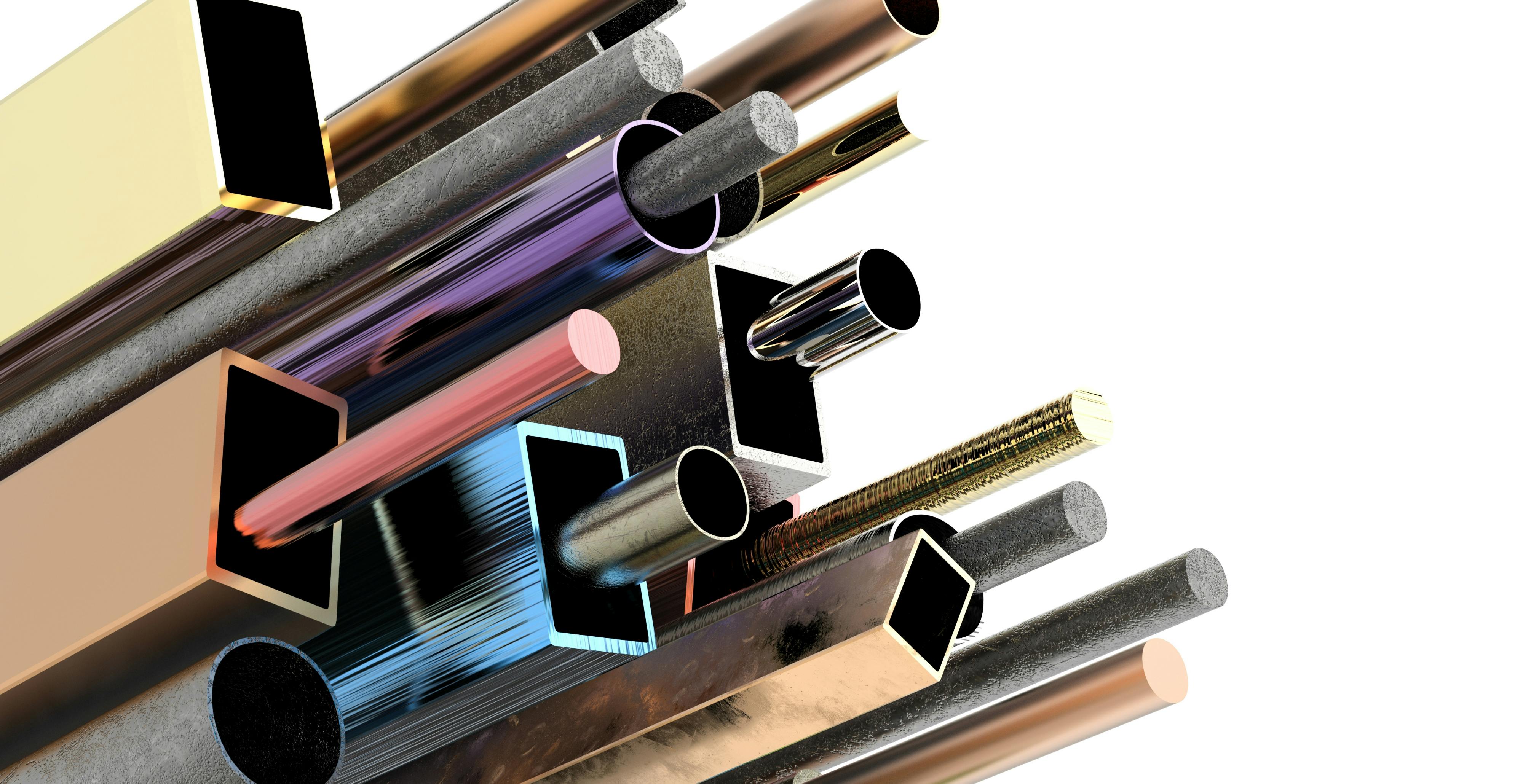

Array of metal extrusions with different finishes

Available Extruded Part Finishes

Xometry makes adding additional finishing steps to your metal extrusion project easy. Our vast network of finishing suppliers allows us to apply a variety of finishes to your parts. We have what you need, whether it’s functional or cosmetic finishes. The finishes we offer for our metal extrusion process are detailed below.

As-Extruded

The finish will be left unprocessed and remain as-extruded. Surface roughness can vary between alloys due to differences in grain structure but typically will fall between 64µin - 125µin Ra. Noticeable grain lines or discolored streaks may be present.

Anodized (Type II Or Type III)

Type II anodizing creates a corrosion-resistant oxide finish. Parts can be anodized in different colors—clear, black, red, and gold are the most common. Type III is a thicker finish and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II. Anodized coatings are not electrically conductive.

Powder Coating

This is a process where powdered paint is electrostatically sprayed onto a part, then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard wet painting methods. Various colors and textures are available to create the desired aesthetic.

Wet Painting

All extruded metal parts can be wet painted in various paint formulations and colors. For color matching, paint brand and number should be specified on your included drawings or notes.

Plating

Extruded parts can be plated with electroless nickel, nickel, brass, tin, chrome, chromate, Teflon, silver, and gold.

Chemical Film

A chromate conversion coat can be applied to protect aluminum from corrosion and improve the adhesion of paints and primers. Chemical film conversion coatings also allow the metal to retain its electrical conductivity while providing corrosion protection to the surface.

Media Tumbled

Parts are subjected to vibratory media tumbling to remove sharp edges and smooth surfaces. Suitable for smaller pieces that can fit within the bowl or barrel of the tumbler.

Custom

Don’t see the finish you need? Select “custom” in our quoting interface and let us know what you are looking for, and we will be happy to explore additional options for you!

Ready to get started on your extrusion quote?

Applications of Extrusion

Metal extrusion products can be found all around us in our daily lives. You can find them from metal windows and door frames to structural components for architecture and airplanes. Metal tubing, shaped bars, and angle stock are all created through extrusion. Many custom manufactured parts are made from these standardized extruded shapes. Metal extrusion is often the best, if not the only way, to create components with continuous complex cross-sections at scale while remaining economical. Some industries that use the process include automotive, aerospace, marine, architecture, construction, food processing, and electronics.

- Aircraft structural components

- Window frames, door frames, trim

- Electrical connector housings

- Conveyors

- Ladders and scaffolding

- Complex thin walled enclosures

- Heat sinks

Metal Extrusion Advantages and Disadvantages

Advantages of Metal Extrusion

Dimensional Accuracy and Stability

Modern extrusion presses and processes produce close tolerance extruded shapes that are durable and dimensionally stable. The process is also suitable for brittle and ductile materials.

Low Part Cost

With careful design, extruded frames and housings can eliminate multi-part assemblies. High production volume is also easily achievable and economical.

Lower Tooling Cost

The simplicity of the extrusion process yields 80-90% lower tooling costs than other processes like injection molding or die casting.

Part Complexity

Extrusion is well suited for creating parts that have complex cross-section forms, including features such as undercuts, T-slots, and grooves.

Disadvantages of Metal Extrusion

Initial Setup Cost

Aside from the piece cost of the extrusions, there are also costs associated with building the dies and tooling. These costs are represented by tooling and setup fees.

Design Limitations

While the process enables complex profiles, it can be restrictive to design freedom. The reason being is the cross-section of the extrusion must remain constant. Features such as countersunk holes, pockets, or bosses cannot be extruded and will require additional post-machining steps.

Lead Times

The pool of extrusion manufacturers is smaller due to the heavy machinery and facility requirements associated with the process. In addition, lead times for the production and iteration of dies can take weeks. Due to these factors, lead times for initial parts deliveries are typically four to six weeks.

Why Choose Xometry for Extrusion Services?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get started with our easy-to-use platform and let our experts take care of managing the project from locating the right manufacturing partner to delivery logistics.

Vetted Network

We are ISO 9001:2015, ISO 13485, and AS9100D certified. Only the top shops that apply to become suppliers make it through our qualification process.