The aerospace industry is at the forefront of technological innovation, continually seeking new methods to enhance productivity, reduce costs, and improve performance. In recent years, 3D printing (also known as additive manufacturing) has begun to transform aerospace manufacturing, particularly in the areas of prototyping and tooling. By leveraging this technology, aerospace companies can rapidly produce complex prototypes and customized tools with shorter lead times and greater design flexibility.

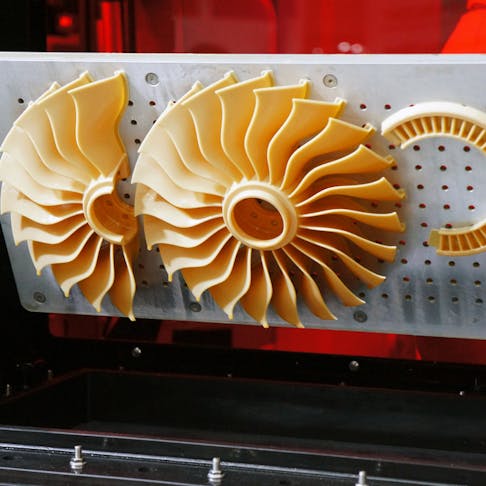

Prototyping and tooling are essential phases in the development cycle, allowing engineers and designers to test concepts, validate designs, and refine components before full-scale production. 3D printing enables the fabrication of lightweight structures, functional prototypes, and intricate geometries that closely mimic final production parts. It also supports the creation of tailored tools for manufacturing, maintenance, and repair applications.

This article explores the critical role of 3D printing in aerospace prototyping and tooling, highlighting its key advantages, practical applications, and impact on design and production workflows.

What Is Prototyping and Tooling in the Aerospace Industry?

Prototyping and tooling play a crucial role in the development and production of aircraft and spacecraft. Prototyping refers to the creation of physical models or replicas that represent a design concept or a specific part/component. These prototypes are used to evaluate and validate the functionality, form, fit, and performance of the design before it goes into production. 3D printing makes the whole process more efficient. It allows for the production of complex geometries and intricate details that would be challenging or impossible to achieve using traditional manufacturing methods. This enables engineers and designers to iterate and refine their designs quickly, reducing development time and costs.

Tooling, on the other hand, is the production of specialized equipment, fixtures, molds, and jigs that are necessary for manufacturing, assembly, and maintenance processes. In the aerospace industry, these tools ensure precision, accuracy, and repeatability in the production of aircraft components. 3D printers enable the production of lightweight and complex tooling solutions, reducing costs and lead times compared to traditional machining methods. You can now create customized tools tailored to specific requirements and produce low-volume or one-off tools more efficiently.

How Long Has Aerospace Used 3D Printing for Prototyping and Tooling?

The aerospace industry began using 3D printing for prototyping and tooling as early as 1989, marking it as one of the earliest adopters of additive manufacturing technology. This early investment reflects the sector’s strong commitment to innovation and advanced production methods. By 2015, aerospace accounted for approximately 16% of the global additive manufacturing market, which totaled $4.9 billion at the time. This figure highlights the industry's continued reliance on 3D printing for creating functional prototypes, custom tooling, and complex geometries, firmly establishing additive manufacturing as a critical capability in aerospace development and production workflows.

How Has 3D Printing Affected Aerospace Prototyping and Tooling?

3D printing can significantly accelerate the design and manufacturing process, allowing for rapid iteration and customization of parts. Additionally, 3D printing enables the creation of complex geometries and intricate internal structures that are difficult or impossible to produce using conventional techniques. This enhances the performance and efficiency of aerospace components. Compared to traditional manufacturing methods such as machining or casting, 3D printing offers greater design freedom, reduces material waste, and lowers tooling costs. It has revolutionized the prototyping and tooling processes, resulting in more efficient production and enhanced product development.

To read more, see our guide on 3D Printing Aerospace Parts.

3D printing has revolutionized the aerospace industry's approach to prototyping and tooling. The ability to create lightweight, customized components on demand is a game-changer. But the technology isn’t without its hurdles—material limitations, high equipment costs, and post-processing demands still create friction. That said, the progress in just the past decade has been impressive, and with continued innovation, these barriers are becoming easier to navigate.Mahder Tewolde, Ph.D., PENote from the Editor

Which 3D Printing Materials Are Utilized for Aerospace Prototyping and Tooling?

The aerospace industry employs a range of advanced 3D printing materials to meet strict performance, durability, and weight requirements in prototyping and tooling. Below are the most common 3D printing materials used for prototyping and tooling in the aerospace industry:

1. Nylon (Nylon 12)

Nylon 12 is a high-performance thermoplastic commonly used in aerospace applications due to its exceptional strength-to-weight ratio, thermal stability, and chemical resistance. It also exhibits good impact resistance, fatigue durability, and dimensional stability, making it highly suitable for functional prototypes and production-grade tools.

In aerospace prototyping and tooling, Nylon 12 is often used for components such as brackets, clips, housings, and fixtures, where lightweight yet mechanically robust parts are critical. Its ability to maintain dimensional accuracy during the printing process ensures repeatability and reliability, even in high-temperature or chemically aggressive environments. 3D-printed nylon parts offer a reliable and cost-effective solution for validating designs and supporting production, thereby contributing to streamlined manufacturing and accelerated development cycles in the aerospace sector.

To learn more, check out our guide on Nylon Plastic Material.

2. Titanium

Titanium is a high-performance metal valued in aerospace for its exceptional strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. These properties make it ideal for use in high-stress, high-temperature, and corrosive environments, particularly at the interface between metallic and carbon-fiber-reinforced polymer (CFRP) components. In aerospace prototyping and tooling, titanium is commonly used for fastening elements, structural airframe parts, landing gear components, and engine-related hardware. Its low density and high tensile strength make it especially attractive for aero-engine manufacturers, where reducing weight without compromising strength is critical.

Titanium's high-temperature stability is essential for components such as blades, discs, casings, and shafts in jet engines and propulsion systems. Its use in both prototyping and tooling contributes to longer part life, higher performance, and improved thermal resistance, supporting the demanding conditions of modern aerospace operations.

To learn more, check out our guide on Titanium.

3. Inconel®

The popular alloy, Inconel®, is especially valuable in applications involving extremely high temperatures, such as those present in jet engines. When subjected to high heat, Inconel® forms a protective oxide layer that further enhances its heat resistance. These alloys also have exceptional resistance to corrosion, oxidation, and pressure. The aerospace industry heavily relies on Inconel® for many high-performance mechanical parts. Flame holders, gas turbine rotors, seals, afterburner parts, and blades are just a few of the aerospace components made from Inconel® alloys.

To learn more, read our guide on Inconel Metal.

4. Polycarbonate (PC)

Polycarbonate (PC) is a durable thermoplastic widely used in aerospace for its impact resistance, flame retardancy, and thermal stability. It is especially well-suited for backlit instrument panels, wire and cable protective casings, and other components requiring strength, transparency, and heat resistance. Polycarbonate's flame and impact resistance make it a safe and reliable material for prototyping components that may be exposed to high temperatures or harsh environmental conditions. In aerospace tooling, polycarbonate material is often used to create jigs, fixtures, and assembly aids, where dimensional stability and mechanical strength are essential for repeated use in production environments.

What Are the Advantages of 3D Printing for Prototyping in the Aerospace Industry?

3D printing offers numerous advantages for aerospace prototyping, enabling faster development cycles, reduced costs, and improved design flexibility. Key benefits include:

- Faster Iteration: Additive manufacturing enables rapid production of physical prototypes, significantly shortening design and testing cycles. Engineers can quickly evaluate and modify designs, accelerating the path from concept to validation.

- Cost Efficiency: Traditional prototype manufacturing often requires costly tooling and machining. 3D printing eliminates the need for custom tooling, enabling the production of complex geometries at a more economical cost, particularly in low-volume or one-off builds.

- Design Freedom: 3D printing supports the creation of complex, lightweight, and topology-optimized structures that would be difficult or impossible to fabricate using subtractive or forming methods. This flexibility encourages innovation and performance optimization.

- Customization and Personalization: Aerospace prototypes often require customization based on specific requirements or individual preferences. 3D printing makes those projects simpler, enabling the production of personalized components or modifications to existing designs.

- Less Material Waste: Unlike subtractive manufacturing, which removes material from a larger block, 3D printing is additive—material is deposited only where needed. This leads to significantly lower waste, improving material efficiency and sustainability.

- Lightweight Component Production: One of the most valuable advantages in aerospace is the ability to create lightweight yet structurally sound parts. 3D-printed components can be up to 50% lighter than traditionally manufactured parts, directly contributing to improved fuel efficiency and payload optimization in aerospace systems

One of the most unique ways I've seen large format 3D printing used in aerospace is doing full-scale mockups of items such as nose cones and orbital maneuvering systems for fit checks before the final products are madeGreg PaulsenDirector, Applications Engineering

What Are the Challenges of 3D Printing for Prototyping in the Aerospace Industry?

While 3D printing offers significant advantages for aerospace prototyping, it also presents several challenges that must be carefully managed to ensure cost-effectiveness, quality, and feasibility. These challenges include:

- High Cost of Raw Materials: Aerospace-grade 3D printing materials, such as titanium powders and high-performance polymers (e.g., ULTEM or PEEK), are often expensive. The material cost can significantly increase overall prototyping expenses, particularly for large or structurally demanding components.

- Limited Build Volumes: Each 3D printer has a maximum build size, which may not accommodate large aerospace parts in a single print. As a result, oversized prototypes may need to be printed in segments and assembled, introducing additional complexity and potential structural weaknesses.

- Post-Processing Requirements: Many 3D-printed parts require post-processing, such as support removal, surface smoothing, heat treatment, or coating, to achieve aerospace-quality surface finishes and tolerances. These steps add time, labor, and cost to the prototyping process.

- Design Limitations: Despite the design freedom offered by 3D printing, certain geometries present significant challenges. Overhangs, unsupported features, and orientation-related warping can affect print quality. Design for Additive Manufacturing (DfAM) principles must be followed to optimize geometry and minimize the use of support material.

- Slow Production Speed for Complex Parts: 3D printing builds objects layer by layer, which can be time-consuming—especially for large, dense, or highly detailed prototypes. Printing speed is influenced by factors such as part geometry, material type, layer thickness, and machine capabilities. In high-volume prototyping or time-sensitive projects, this can be a limiting factor.

Summary

This article presented aerospace prototyping and tooling with 3D printing, explained what it is, and discussed its various applications. To learn more about 3D printing in aerospace, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D prinitng and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Copyright and Trademark Notices

- Inconel® is a registered trademark of Special Metals Corporation.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.