Heat sinks are widely used in electronics to manage component temperatures. They work by increasing surface area to enhance heat transfer to the surrounding fluid, typically air. Active heat sinks use fans to increase airflow, while passive designs rely solely on natural convection. Different devices need different heat sinks based on cost, location, and cooling requirements. Thermal resistance directly impacts the effectiveness of a heat sink. Listed below are the six things to consider when choosing heat sinks:

1. Determine the Thermal Requirements of Your Component

The thermal requirements are the amount of heat energy dissipated per unit of time. They must first be established to set up the criteria for choosing a heat sink. If the proper thermal requirements are not established, then it will not be possible to choose the appropriate heat sink for the application. By identifying the thermal requirements, designers can select a heat sink that maintains safe operating temperatures and supports optimal component performance.

2. Choose the Appropriate Heat Sink Type

Heat sinks come in two broad types: active (which use fans to boost airflow) and passive (which rely on natural convection). The choice depends on your cooling requirements, noise sensitivity, and available airflow. Selecting the right type helps reduce maintenance, control costs, and optimize thermal performance.

3. Calculate the Thermal Resistance of the Heat Sink

The thermal resistance of the heat sink is a measure of how well a heat sink conducts and dissipates heat. The surface area, size, and material of the heat sink all affect its thermal effectiveness. A simplified formula to estimate thermal resistance is:

Thermal Resistance (°C/W) = Thickness / (Thermal Conductivity × Surface Area)

However, real-world calculations often require accounting for convection coefficients, fin efficiency, and airflow conditions. Accurate thermal resistance calculations help ensure the most effective heat sink is selected.

4. Determine the Airflow Available

The airflow available is the amount of air that flows over a heat sink in a given period. For passive systems, this is the established airflow; for active systems, it is the airflow created by the fan. Determining airflow helps assess the effectiveness of the thermal system. Higher airflow usually indicates better heat sink efficiency. Passive heat sinks are designed for natural convection and may not significantly benefit from added fans unless specifically engineered to support forced airflow. It may also be better to use established airflows as the addition of fans will create noise, and the end-user will usually want the device to be as quiet as possible.

5. Choose the Appropriate Heat Sink Size

The bigger the heat sink, the more heat it will be able to dissipate. However, the heat sink’s size is limited by available space and contact area. A larger heat sink isn’t always more effective, as other factors also play a role. Other variables such as material conductivity, airflow, and thermal resistance of the design are also factors.

6. Consider the Thermal Interface Material

The thermal interface material is the substance that sits between the heat sink and the component it is cooling. The interface is used to effectively transfer heat from the component to the heat sink. The interface may be referred to as:

- Thermal grease

- Heat sink compound

- Thermal compound

- Gap filler

- Thermal paste

Without the right choice of a thermal interface material (TIM), the interface thermal resistance may increase significantly, reducing the overall effectiveness of the heat sink.

What Is a Heat Sink?

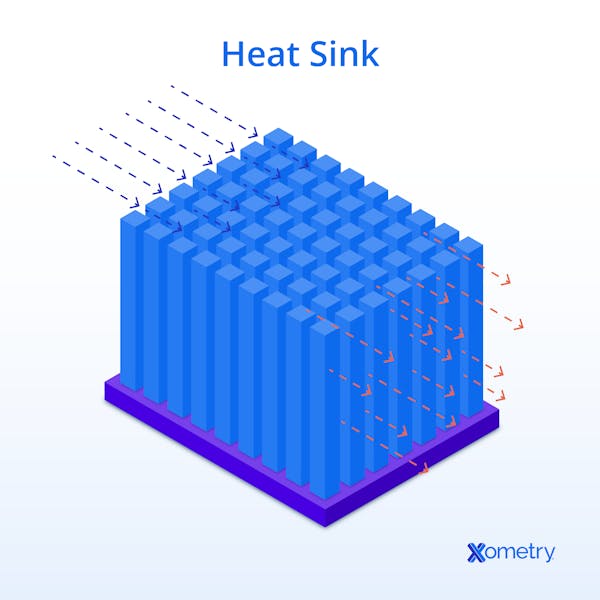

A heat sink is a device used to dissipate heat away from electronic components, thereby reducing their operating temperature. It could be as simple as a metal plate on a printed circuit board to increase thermal conductivity. Heat sinks are commonly finned metal structures that increase surface area for heat dissipation. In active cooling setups, they are often combined with a fan to enhance airflow. For more information, see our guide on What is a Heat Sink?

How Does a Heat Sink Work?

A heat sink works by increasing the transfer rate of heat from the hot solid medium to a less hot or cool fluid medium. The heat sink achieves this with the use of pins or fins to increase the surface area and sometimes with the aid of a fan to increase the flow rate. The rate at which heat is dissipated is determined by the heat sink size, type, material, and location.

Why Do Different Devices Need Heat Sinks?

Different devices need heat sinks to remove heat from areas that need to stay cool. Heat sinks disperse heat to prevent overheating. Without proper thermal management, excessive heat can increase electrical resistance, accelerate material degradation, and reduce component performance and reliability.

What Are Heat Sink Types?

Heat sink designs vary in geometry and manufacturing method. These six types differ in geometry, material use, thermal performance, and manufacturing cost. Some are better suited to active systems, while others work well in passive setups. Most are made from aluminum or copper due to their high thermal conductivity. There are six heat sink types that can be part of an active or passive system. They are commonly made of either aluminum or copper. The active systems use a fan to induce extra airflow over an area to improve cooling. The passive system relies on increasing the surface area of the component to allow more heat to be dissipated. Listed below are the types of heat sinks:

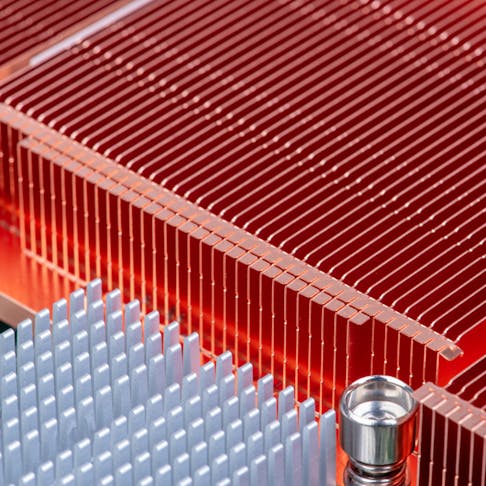

1. Bonded Heat Sinks

Bonded heat sinks are manufactured by using a conductive epoxy to adhere fins to a base. They can be made of either copper or aluminum or a mixture of both aluminum and copper. Bonded heat sinks are used for applications that require a high fin density. They have a much higher fin density than extruded heat sinks. This increased fin density is best used in an active system with forced airflow. The size of the bonded heat sink is virtually unlimited, and so they are generally used for applications that require very large heat sinks.

2. Skived Heat Sinks

Skived heat sinks feature a series of tightly packed fins on a base that has been manufactured in one piece of metal, which results in minimal thermal resistance. They are used in applications with high airflow and minimal space. Skiving offers a balance between performance and cost, especially for high-density fin designs in moderate production volumes. Skived heat sinks are made out of copper or aluminum. The maximum width of a skived heat sink is approximately 400 mm with a height of 200 mm. However, the length of the heat sink is only bound by the length of the copper bar that is used. Skived heat sinks have a dissipation capacity of around 1.5–2 times that of a bonded or soldered heat sink.

3. Extruded Heat Sinks

Extruded heat sinks are the cheapest to manufacture as the process involves extruding one long piece of metal continuously in a cross-section that forms fins and a base together. These heat sinks are used for high-powered semiconductor devices and in medium to high airflow applications. While copper heat sinks can be extruded, most extruded heat sinks are aluminum. Extruded heat sinks are available up to a width of 400 mm and a height of 60 mm. Since they are extruded, the length is unlimited.

4. Forged Heat Sinks

Forged heat sinks are manufactured using compressive force to shape the metal. Forged heat sinks are often made of aluminum or copper. Aluminum is more commonly used due to its lower cost and good thermal properties, while copper offers higher conductivity but is more expensive and harder to forge. They use either fins or pins to disperse heat. Forged heat sinks have low thermal resistance as there is no medium between the fins/pins and the base. They have a length and width of around 500 mm and a height in the 70 mm range.

5. Stamped Heat Sinks

A stamped heat sink is produced by stamping the fins out of sheet metal. The stamped metal fins are then held together using one or more zipper fins, which are perpendicular to the normal fins and interlock to keep the distance. Stamped heat sinks are low-performing and are used in low-power applications. The set of fins is usually soldered to the base. The size and geometry of the fins can be adjusted by using a different stamp.

6. CNC Machined Heat Sinks

CNC machined heat sinks are best used for one-time production requirements, as they are not cost-effective to repeat, and there are no extra tooling requirements for a one-off heat sink. Machined heat sinks are typically used for custom, low-volume, or prototype applications where tooling costs must be avoided. Copper is hard to machine, so machined heat sinks are mostly aluminum. The size of the heat sink will be limited by the capacity of the CNC machine used.

What Are the Benefits of Using Heat Sinks for Different Applications?

The main benefits of using heat sinks for different applications are:

- Increased device efficiency

- Increased device performance

- Increased device life span

- Prevent overheating

- Keep components within the temperature range they are designed to operate in

What Are the Challenges in Determining the Right Heat Sink for Your Applications?

The biggest challenge is that the performance of one heat sink type will vary depending on the environment in which it is used. Factors that will affect the choice of the heat sink are:

- How the airflow interacts with the design

- How the heat from surrounding components affects the heat sink

- The space restrictions of the location

- The budget for a heat sink

The best way to overcome these challenges is to use thermal modeling tools to simulate heat dissipation and airflow under expected conditions, followed by validation through physical testing.

Common FAQs On How to Choose a Heat Sink

How Does the Design of the Heat Sink Affect Its Performance?

The main factors affecting heat sink performance are material, type, and location. If the material used has a high thermal resistance, it will not be an effective heat sink. So choosing a low-resistance material is key. However, thermal resistance can increase if the design introduces additional interface layers—such as those found in bonded, soldered, or mechanically assembled fin structures—because each layer adds a potential barrier to heat flow. The location and orientation of the heat sink will also affect its performance. Heat sinks should channel airflow parallel to the fins to maximize the surface area between the air and the heat sink.

How Is the Material Composition a Factor for Excellent Heat Dissipation?

The ability of a material to dissipate heat is influenced by its thermal conductivity, which is closely related to the number of free electrons in metals. Materials with high thermal conductivity, like copper and aluminum, are commonly used for heat sinks because free electrons help transfer heat efficiently through conduction. For more information, see our guide on What is Aluminum Alloy?

How Do Heat Sinks Contribute to the Efficiency and Reliability of Electronic Devices?

As the temperature of a device increases, its efficiency and reliability will decrease. This is because as the temperature increases so does the resistance. Therefore, to increase reliability and efficiency, heat sinks are used to moderate the heating effect.

Does a Bigger Heat Sink Mean High Thermal Management?

Yes, a bigger heat sink can result in better thermal management. However, this will only be true if the right heat sink is selected for the application. Often, heat sinks are constrained by the other components around them, so a bigger heat sink is not always possible. In addition, a well-optimized heat sink design, featuring effective fin geometry, material choice, and surface area, can outperform a larger one that lacks these optimizations.

Do Heat Sinks Need Thermal Paste?

Yes, heat sinks do need thermal paste to transfer heat from the component to the heat sink effectively. If thermal paste, or thermal paste substitute, is not used, the thermal resistance between the heat sink and the component is increased, which will negatively affect the heat sink performance.

Do Heat Sinks Perform the Same Principle As Heat Spreaders?

No, heat spreaders do not work on the same principle as heat sinks. Heat sinks transfer heat to a fluid medium like air, water, or oil. Heat spreaders distribute heat laterally across a larger surface area to prevent localized hotspots, while heat sinks transfer heat into a cooling medium (usually air) via convection. Though both manage heat, they operate by different thermal transfer mechanisms. Heat spreaders can be used in sealed units, whereas heat sinks often use fans to move airflow over the heat sink. For more information, see our guide on What is a Heat Spreader?

Summary

This article presented heat sinks, explained what they are, how they work, and showed six things to consider when choosing one for your application. To learn more about choosing heat sinks, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.