3D printing is a difficult-to-master manufacturing technique, but it can provide a wide range of benefits. However, as with any machine, a 3D printer will fail over time and will need to be repaired to function optimally.

Listed below are eight steps that can be followed to diagnose and repair a typical 3D printer. These steps are relevant regardless of the exact type of 3D printer used.

1. Identify the Specific Issue With the 3D Printer

When a 3D printer fails, it is important to determine the specific cause of the failure. For example, is the material not being fed from the extruder? Do the prints come off the build plate? If something was recently changed — for example, the material, the slicer, or the firmware — then this could be a likely cause. If the printer simply stops working all of a sudden, a more thorough analysis must be performed. Always start with the most basic potential causes first. Did a power cord become loose? Is the memory card or USB stick containing the print files properly plugged in? Or is there clear physical damage on critical components of the printer?

2. Inspect for Visible Damage, Such as Loose Screws or Disconnected Cables

Inspect the physical condition of the printer. Check all fasteners, such as screws or bolts, and tighten them if loose. Next, make sure the power cable is properly connected to both the printer and the wall socket. If accessible, check that the cables to the control board and other electronics are securely connected. Do not open any panels on the printer as it will void the warranty.

3. Refer to the Printer's Manual for Troubleshooting Guidance

All 3D printers are supplied with either a physical or a digital maintenance and operating manual. Refer to the “troubleshooting” section for common issues, their causes, and how to fix them. This section is usually in the form of a table. In some cases, the troubleshooting section will refer to other areas in the manual for detailed steps. The digital version of the manual can usually be found on the OEM’s (original equipment manufacturer’s) website.

4. Follow the Recommended Procedures Outlined in the Manual

It is important to diligently follow the step-by-step supplier recommendations found in the manual. 3D printers are complicated tools and can easily be damaged if the steps are not followed exactly. It is also important not to attempt any repairs that are not specifically referenced in the manual. This can result in the warranty being voided or the printer becoming permanently damaged.

5. Check for Compatible Replacements if a Part Is Defective

If all the advice is followed in the manual and the 3D printer still does not work as expected, there may be a defective part. The troubleshooting process should help highlight which specific component is defective. If the printer is designed with repairability in mind, then it should be simple to remove the defective part and replace it with a new one.

For hobbyist-style 3D printers, there is a large aftermarket scene with many different replacement parts available. In some cases, these may be upgrades from the current part, but in other cases, they could negatively impact the printer's performance as these parts might not meet original OEM specifications. It is always best to purchase OEM-recommended spare parts.

6. Ensure Firmware and Software Are Up to Date

Manufacturers are continuously updating printer firmware to both improve functionality and fix any potential bugs. In some cases, a 3D printer can fail simply due to the firmware being out of date, for example, changes in the way the machine defines the homing (zero) point can cause the machine to crash. It can be challenging to update the firmware with low-budget 3D printers but for most modern printers, the update process is usually automatic.

It must also be noted that a firmware update can introduce new bugs so, in some cases, reverting to a previous version of the firmware can solve the problem.

The software used to prepare models for 3D printing, sometimes called the slicer, can similarly require periodic updates to remove any bugs and/or improve functionality. Make sure this software is also updated, as a corrupted slicer file will result in a messy 3D print failure.

7. Perform Regular Maintenance, Including Cleaning and Lubricating Moving Parts

The key to the longevity of any machine is regular maintenance. The operating and maintenance manual supplied with the 3D printer would normally include a table of maintenance activities with the corresponding maintenance frequency. Failing to adhere to this maintenance schedule can reduce the life and effectiveness of the 3D printer.

In general, the 3D printer should be kept clean at all times, and a buildup of dust and 3D printing material should be avoided. 3D printers make use of linear rails to guide the extruder and printing bed along the 3 axes of motion, these guides are designed to be extremely precise and should be kept clean and free of obstructions.

Lubrication is usually recommended to keep these linear rails operating smoothly. The exact type of lubricant and method of lubrication can be found in the operating and maintenance manual.

8. Seek Assistance From Online Forums or the Manufacturer's Support Channels if the Problem Persists

If all else fails, it might be best to search for solutions to similar issues online, in online forums, 3D printing YouTube channels, and by reaching out via manufacturer support channels. Online forums can provide a useful source of information, as there is a chance that another user has experienced the same problem. However, online forums can also provide bad advice or simply incorrect information. It is generally better to first engage with the manufacturer’s support network when trying to solve a stubborn problem. Some manufacturers will even offer to replace faulty components if the issue is due to a factory defect.

What Is a 3D Printer?

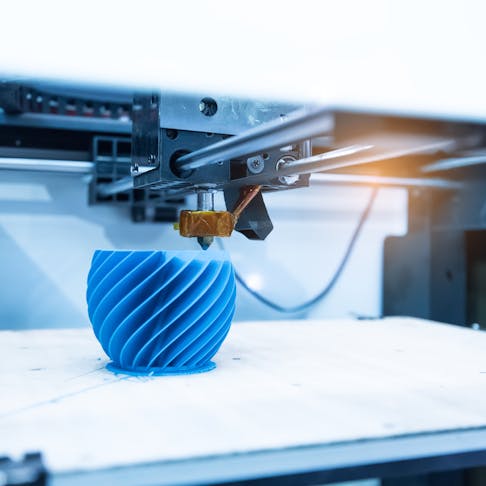

A 3D printer is a fabrication tool designed to produce complex components in a wide range of plastics, metals, and ceramics using a technique called additive manufacturing. Additive manufacturing refers to the process of building a component one layer at a time on a build plate, fusing each layer with the previous one. There are many different 3D printing technologies. Three of the most common are described below:

- FFF (Fused Filament Fabrication): The part is built from thermoplastics that are melted and extruded from a nozzle. The nozzle traces out the shape of the layer, and the newly melted plastic fuses it with the previous layer.

- SLA (Stereolithography): The part is built from a UV-sensitive polymer that cures when exposed to UV light from an LCD screen that represents the cross-sectional shape of that specific layer. The polymer cures when exposed to the light, fusing to the previous layer. Some SLA machines use a laser to cure the part, rather than an LCD screen.

- SLS (Selective Laser Sintering): The part is built from a meltable thermoplastic, ceramic, or metal powder. A thin layer of powder is spread onto the build plate and a laser traces out the cross-section of the part, fusing the powder to itself and the previous layer.

What Are Common 3D Printer Issues?

There are many different 3D printer technologies available, and each has its own set of typical challenges. Some general 3D printer issues are described below:

- Incorrect Calibration: When setting up a new 3D printer, it is important to ensure that the printer is properly calibrated. For example, correctly setting the height of the nozzle from the build plate in an FFF printer is critical, as the wrong setting can result in poor prints or can even damage the printer. The same applies to SLA 3D printers, where the build platform should be a certain height from the film.

- Firmware: Outdated firmware can be a frustrating problem to solve, as it is usually the last thing to check and can be difficult to troubleshoot as it requires gaining access to the software and running through the code to isolate the issue, this can be challenging for the average user. Firmware updates can also introduce new issues. In this case, it can be useful to check online forums to see whether other users are experiencing similar issues after a firmware update.

- Low-Quality Material: 3D printing materials can be expensive. It may be tempting to use cheaper alternatives. However, in most cases, companies offering “budget” materials do not carry out proper quality control and the resulting products can give inconsistent performance. Low-quality material can damage the 3D printer.

- Poor Maintenance: Poor or non-existent maintenance will always reduce the life of a 3D printer and can also result in anomalous behavior during printing, i.e. higher failure rates during the printing process.

What Part of a 3D Printer Normally Encounters Issues?

Each type of 3D printing technology has its own set of typical issues. Listed below are some common issues with standard 3D printing technologies:

- FFF (Fused Filament Fabrication): The hot end, specifically the nozzle, is often the root cause of many fused filament fabrication failures. The nozzle can become blocked or worn out (especially with abrasive filaments), or the hot end heater or temperature control may fail, preventing the proper melting behavior of the plastic filament.

- SLA (Stereolithography): The plastic release film onto which the print attaches and the LCD (Liquid Crystal Display), which is used to cure the resin, commonly fail on an SLA printer. These are both considered consumables and should be replaced when they begin to show signs of wear or at specified intervals.

- SLS (Selective Laser Sintering): While not the cause of regular failures, the laser system on an SLS printer can begin to degrade, resulting in insufficient or uneven heating, which can cause the printed product to have an unexpectedly low level of strength.

Does the Wrong Installation of a 3D Printer Cause a Problem?

Yes, if a 3D printer is not installed and set up correctly, it is almost certain that there will be eventual problems. Even if there is no problem initially, a problem can still appear later on. Late onset of defects caused by improper installation can be difficult to trace back to the faulty installation.

How To Choose The Best 3D Printer Technician

Choosing a 3D printer technician can be challenging, as it is difficult to determine beforehand if they possess the relevant experience. It is recommended to contact the manufacturer to recommend a certified repair technician. This will ensure that only approved parts are used and that the repair work follows the recommended procedures.

How Much Does a 3D Printer Repair Cost?

The cost of a 3D printer repair depends on many factors, such as the type of 3D printer, what was damaged, and how good the after-sales support is for the specific 3D printer brand. For example, replacing the hot end of an FFF printer can cost tens of dollars, whereas replacing the LCD screen of an SLA 3D printer can easily cost a few hundred dollars. The repair costs get significantly higher when it comes to SLS printers, whose laser components can cost thousands of dollars.

What Is the Best 3D Printer Repair Service Provider?

It is difficult to single out any particular repair service provider. For the best quality work, the OEM is always the best option. Barring that, the OEM-recommended service providers are the next best option, as they are bound to work according to the OEM processes and procedures.

Are Maintaining and Repairing a 3D Printer the Same Thing?

No, maintenance and repair are two distinct concepts. Maintenance procedures (such as lubrication) are carried out intermittently to prevent failures. Repairs are undertaken to fix components and systems after they break. Insufficient maintenance can cause the machine to fail, necessitating repair work.

What Is the Difference Between Repairing a 3D Printer and Maintaining a 3D Printer?

Repairing a 3D printer refers to the process of replacing a defective component that has failed during normal or abnormal usage. Maintaining a 3D printer refers to the activities that can extend the operating life of the 3D printer while ensuring optimal performance. Maintenance procedures are often carried out at specified intervals. These activities can include cleaning and lubrication, among others.

Summary

This article presented how to repair a 3D printer, explained each step, and discussed its common 3D printer issues. To learn more about repairing 3D printers, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.