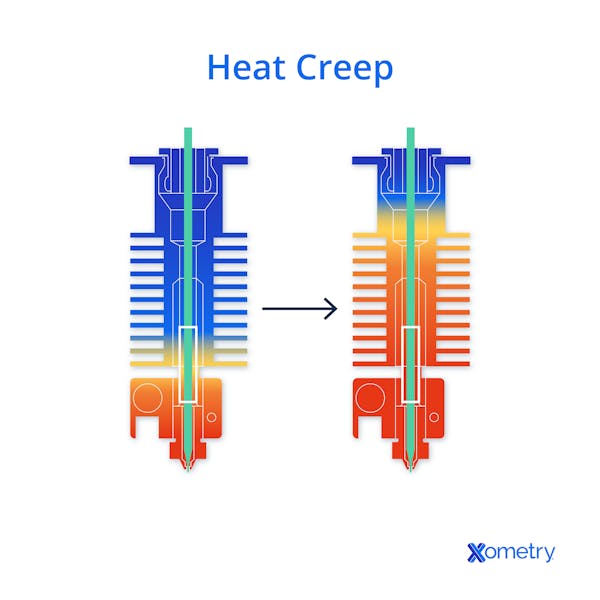

Heat creep in Fused Deposition Modeling (FDM) 3D printing refers to the undesired upward transfer of heat from the hot end of the extruder into the cooler zones of the extruder assembly. When this occurs, the filament may prematurely soften or partially melt above the intended melt zone. This softening can cause the filament to swell, leading to partial or complete clogs within the extruder. In addition to causing extruder blockages, heat creep can result in inconsistent extrusion, degraded print quality, and material waste. It is a common issue, especially when printing with heat-sensitive filaments or when using insufficient cooling.

This article outlines 10 effective methods for preventing heat creep, along with a detailed explanation of its causes, symptoms, and the impacts on part quality in FDM 3D printing.

1. Test the Cooling Fan

Ensure the extruder’s cooling fan is operating at its rated capacity. If the fan fails or underperforms, excess heat will not be effectively dissipated from the heat sink, leading to thermal migration up the extruder. Begin by verifying the voltage supplied to the fan using a multimeter. It should match the fan’s rated voltage (typically 12V or 24V). Inadequate voltage leads to lower fan RPM, reducing cooling efficiency and accelerating heat creep. If the fan is spinning too slowly or intermittently, replace or troubleshoot the power supply, wiring, or the fan itself.

2. Modify the Fan's Speed

Increasing fan speed improves convective heat transfer by increasing airflow over the heat sink and other critical components. Higher air velocity enhances turbulence, increasing the heat dissipation rate. Fan speed can typically be controlled through slicer software settings or firmware configurations. Optimizing fan speed is one of the most accessible ways to combat heat creep without requiring hardware changes.

3. Employ a Hot End of Greater Quality

Not all hot ends are made equal. Cheaper hot ends may not be engineered appropriately to prevent heat from creeping up the extruder. They can do so with heat sinks, improved cooling designs, and materials with low thermal absorption to contain heat where it is needed. Higher-quality hot ends not only reduce heat creep but also print more precisely. This is one of the best ways to avoid heat creep.

4. Use a Better-Quality Filament

Low-quality filaments can exhibit inconsistent temperature profiles, so one batch may have different thermal properties than the next. This means that heat creep can be nonexistent in one batch and then become a problem in the next. Poor-quality filament may also have an inconsistent diameter. Heat creep easily affects large-diameter filaments because the plastic does not need to expand as much to cause a blockage.

5. Boost the Print Speed

The print speed must be quick enough to prevent heat from traveling up the extruder and melting the plastic before it can pass through the nozzle. If you stop the filament from spending enough time at elevated temperatures to soften before it reaches the heated extruder, it won’t expand and cause blockages.

6. Reduce the Printing Temperature

The print temperature can be reduced to prevent heat from building up too quickly within the extruder. However, most filaments work within a narrow temperature range; they must melt enough to extrude properly but remain viscous enough to adhere to the previous layer. Lower temperatures and lower viscosities can also cause nozzle blockages. In addition, if you reduce the temperature while increasing the fan and print speed, your filament may not heat up enough.

7. Boost the Retraction Speed

If the retraction is too slow, the heated plastic inside the extruder may have time to swell, causing a blockage. It is most likely to happen a few hours into a print, once the top end of the extruder has heated enough to cause this swelling.

8. Reduce the Retraction Distance

Retraction prevents plastic strings from forming between two elevated features during hot-end movement when no extrusion is occurring. The filament is retracted back into the hot end to prevent any plastic seepage. However, if it retracts too far, softened plastic might contact the extruder drive. The mesh wheel will be unable to engage the soft filament, so it will stop extruding. In addition, melted plastic might stick to areas not protected by the low-friction PTFE insert in the hot end.

9. Use a Cooling Shroud

A cooling shroud can help channel ambient air from the fan toward the heat sink more effectively. This will improve heat transfer from the heat sink and prevent heat from creeping up the extruder.

10. Check for Clogs

Over time, plastic and debris can build up on the extruder’s heat break. This will then affect the heat transfer rate and can cause heat to creep up the extruder. As such, it is essential to regularly check for any clogs or buildup of foreign debris.

Why Should 3D Printing Avoid Heat Creep?

Heat creep during 3D printing can lead to poor-quality prints or even complete failures due to blockages in the extruder that prevent plastic from flowing. Blockages that are caused by heat creep are harder to remove than others because the heated portion swells beyond the tube’s design dimensions. In addition, removing blockages caused by heat creep is more challenging because the plastic inside the hot end has swelled. You may have to completely disassemble the extruder to remove the blockage.

Why Does Filament Quality Matter in Preventing Heat Creep?

Poor-quality filament can have an inconsistent melting range, making it hard for you to maintain optimal settings to prevent heat creep. One method of preventing heat creep is to reduce the temperature as low as possible, but if the melting point is inconsistent, this can cause blockages. Additionally, low-quality filament spools can have diameter inconsistencies, which can also cause blockages. If the filament is oversized to start with, it will expand less under heat creep conditions to cause a blockage.

For more information, see our guide on 3D Printing Filament.

What Is Heat Creep in 3D Printing?

Heat creep in 3D printing refers to the process by which heat from the hot end of an extruder creeps up the extruder assembly and may heat and soften the filament too far from the nozzle. This heating will cause the plastic to swell and can cause blockages in the extruder.

For more information, see our Heat Creep.

What Are the Causes of Heat Creep?

Heat creep causes a wide range of issues during 3D printing. Some of the more common ones are listed below:

1. Poor Cooling

Insufficient cooling will further exacerbate heat creep through the hot end. Poor cooling is caused by a poor hot-end design, an inefficient heat sink design, and a low fan speed.

2. High Printing Temperature

An excessively high printing temperature will equate to a larger temperature gradient between the hot end and the extruder assembly. This will increase the heat creep rate.

3. Retraction Distance

A long retraction distance can cause heated plastic to move too far back into the extruder assembly. This will cause blockages and extrusion issues, with the extruder drive squeezing the softened filament rather than gripping and moving it.

4. Printing Speed

A slow printing speed gives the filament more time to heat up along its length, which can lead to blockages.

5. Filament Quality

Poor-quality filament has an inconsistent cross-sectional diameter and inconsistent melt ranges. Both of these issues can increase the likelihood of heat creep.

6. Hot End Design

Poorly designed hot ends will not effectively isolate the hot portion of the extruder from the upper portions of the extruder assembly.

7. Hot End Clogs

Clogs inside the hot end can prevent existing heat-transfer isolating features from functioning properly. Inspect your printer’s hot end regularly to avoid heat creep caused by clogs.

Heat creep, a common issue in FDM 3D printing, occurs when excess heat travels upward from the hot end, causing the filament to soften too early and resulting in clogs or extrusion problems. The article explores ten effective prevention strategies, from optimizing fan performance and adjusting print settings to using high-quality components and materials, to maintain consistent cooling and filament flow. By managing temperature, speed, and airflow, these methods help ensure smoother operation, prevent print failures, and improve overall part quality.Mahder Tewolde,Ph.D., PE

What Are the Effects of Heat Creep in 3D Printing?

Heat creep can cause several undesirable effects during 3D printing. Some of the more common ones are listed below:

1. Clogs

Clogs during printing can result in inconsistent extrusion, complete blockages, and poor print quality. These are caused by heat creep, in which the filament melts and expands before it has a chance to exit the nozzle. This melted plastic can adhere to the areas in the extruder where there is no non-stick PTFE sheath.

2. Under-Extrusion

Heat creep can cause the filament to partially block the nozzle. These partial blockages can cause inconsistent extrusion rates, resulting in insufficient plastic being printed. 3D printing under-extrusion will result in poor interlayer adhesion.

3. Warping

Warping occurs when the adjoining layers cool at significantly different rates. This causes the layers to warp due to excessive contraction of the newly deposited plastic. Heat creep can cause the plastic to heat up too much, creating a large temperature differential between the freshly printed filament and previous layers and leading to warping.

4. Reduced Print Quality

The warping and overheating effects of heat creep can reduce print quality. Interlayer adhesion may also suffer due to inconsistent extruder temperatures caused by heat creep. This will diminish the part’s overall strength.

5. Filament Waste

Heat creep can create blockages that prevent extrusion. This will ultimately result in a failed print, so all the plastic used up to that point will be wasted.

Frequently Asked Questions About Preventing Heat Creep in 3D Printing

How Does Retraction Distance Affect Heat Creep?

The filament retracts slightly when the print head needs to stop printing and move to a different location, preventing trailing melted material. If it is retracted too far, though, the heated filament can heat other parts of the print head beyond their design temperatures and may ultimately cause blockages or other extrusion problems.

What Are the Risks of Not Solving Heat Creep?

If you fail to fix your heat creep problems, you’re likely to get inconsistent results, failed prints, and time-consuming maintenance troubles later on.

Does Heat Creep Require Quick Prevention?

Yes, even though heat creep may take time to show, you should address it immediately once discovered. If you don’t, you’ll likely experience print failures, and your machine’s extruder may need time-consuming maintenance. Adjusting settings like print temperature and fan speed on the fly will reduce the likelihood of creep.

Summary

This article presented ways to avoid heat creep, explained what they are, and discussed each way in detail. To learn more about heat creep, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.