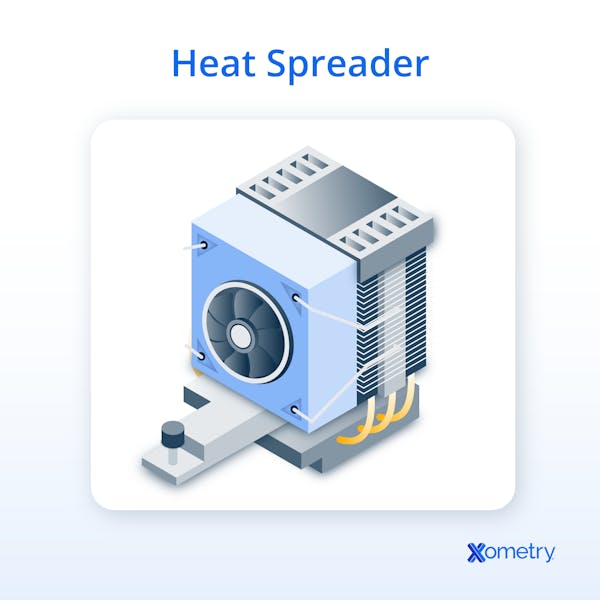

Heat spreaders are objects made of materials with high thermal conductivity that either spread heat from a localized source across a larger surface area, sometimes transferring it to a secondary heat exchanger, heatsink, or dissipating it into ambient air to prevent the overheating of critical components. These heat-dissipating devices are typically made of copper, aluminum, graphite, or diamond. Different types of heat spreaders, including metallic heat spreaders, phase-change devices like vapor chambers and heat pipes, and thermal transfer compounds to fill air gaps, have been designed to maximize heat transfer efficiency for different applications. Heat spreaders are commonly used in computer processors, mobile devices, and automotive electronics, among other things. This article will review what heat spreaders are and explain the different types and applications to ensure you have the information you need to complete your project.

What Is a Heat Spreader?

A heat spreader is an object that facilitates the dissipation of heat from a higher-temperature source to an additional heat exchanger or to a cooler medium, such as ambient air. Heat spreaders are often used in electronics and electrical systems. They are also commonly used in HVAC systems, water heaters, power plants, and other industrial applications.

What Is the Importance of a Heat Spreader?

Heat spreaders are important devices for preventing the overheating of critical components in electronics and industrial systems. Overheating harms the performance of electronics in two ways: it degrades the performance of semiconductors, whose resistivity drops with increasing temperature, as well as the performance of the metallic connections of the electronic components to the rest of the electronic system. This causes the hard drive and processor to slow down. If too much heat is developed without being dissipated, the excessive heat can cause computer systems to crash and damage components.

How Does a Heat Spreader Work?

A heat spreader works by conducting thermal energy from a heat source to either a secondary heat exchanger or to a cooler medium. This can be accomplished using solid pieces of material with high thermal conductivity or by utilizing phase-change mechanisms, such as those found in heat pipes or vapor chambers, which rely on the latent heat of vaporization.

In solid heat spreaders, the heat is conducted through the metal block and away from the source. Phase-change spreaders (like heat pipes) use a sealed, evacuated chamber partially filled with working fluid that vaporizes when heated. The fluid absorbs heat and vaporizes at the evaporator section near the heat source. This vapor then travels through a heat pipe or vapor chamber to a secondary heat exchanger to carry heat away from the source. The vapor then condenses on cooler internal surfaces and repeats the cycle.

“A well-designed heat spreader protects both performance and reliability. It gives components the thermal margin they need to operate consistently under load.”Phillip Keane, Design Engineer & Prototyping SpecialistNote from the Editor

What Are the Components of a Heat Spreader?

Heat spreaders contain one or more of the components listed below:

1. Base Material

The base material forms the primary sheet, block, or gap-filling structure of a heat spreader that transfers heat from the higher-temperature source to the secondary heat exchanger. Base materials must have high thermal conductivity. This makes copper, aluminum, graphite, and diamond good choices.

2. Thermal Interface Material

The thermal interface material (TIM) is a substance placed between the heat spreader and the heat-generating device to help improve heat transfer. TIM is typically a silicone-based thermal grease or thermal paste with metal oxide, silver, or graphite fillers.

3. Fins

Fins are protrusions from the primary body of the heat spreader that enhance the amount of surface area available for convection-based cooling away from the heat source. Ambient air flows between the fins and further removes heat from the fins, and thus from the system, by convection. Fins are usually made from lightweight, high-conductivity metals like aluminum or copper, though they don't need to be the same material as the base.

4. Heat Pipes

Heat pipes are closed pipes consisting of a thermally conductive outer structure, a wick, and a working fluid. One end of the heat pipe lies in the zone that is to be cooled and absorbs heat from it. This heat evaporates the liquid in the wick, on the inside wall of the heat pipe. The resulting gas moves down the center of the pipe to the condenser section, where the cooler walls recondense the vapor in the wick. Capillary action then pulls that liquid back to the hot (evaporator) zone, providing a continuous circulation of cooling fluid within the sealed pipe.

5. Fans

Fans are typically placed in proximity to or integrated with the heat sink or heat spreader. The fans help dissipate heat further due to forced convection.

6. Enclosure

Some electronics don’t have space for heat spreader components. Therefore, large flat enclosures made from copper or aluminum are used to dissipate heat. Enclosures are typically used for electronics that operate in applications with high-vibration environments or in applications where electronics must be protected from the environment.

What Are the Types of Heat Spreaders?

The types of heat spreaders are described in the list below:

1. Metallic Heat Spreaders

Metallic heat spreaders are usually fabricated from copper or aluminum. They are often used in electronics and in industrial applications. Their primary advantage over other types of heat spreaders is that they are easy to manufacture and efficient at dissipating heat. Some disadvantages of metallic heat spreaders are that they can be heavier (especially copper) and that copper is more expensive, though highly thermally conductive.

2. Graphite Heat Spreaders

Graphite heat spreaders are commonly used in consumer and automotive electronics and in batteries. The primary advantage of graphite heat spreaders is that they are lightweight compared to metallic heat spreaders. They are also just as efficient, and can sometimes surpass metals in thermal spreading (in-plane), and can be used in tight spaces. A major disadvantage is that they are brittle. They are also often more expensive than aluminum but generally less costly than copper-diamond composites or high-end materials.

3. Vapor Chambers

Vapor chambers are heat exchange devices, like heat pipes, made from a thermally conductive metal, a wick, and a working fluid. They can be thought of as planar heat pipes. Vapor chambers have an evaporator section in which a liquid absorbs heat from a source. This causes the liquid to transform into gas and move to the condenser area. It then cools and re-forms as a liquid, which circulates back to the high-heat end of the device by capillary action. Vapor chambers are often used in tight, confined spaces such as mobile devices or laptops. A major advantage of vapor chambers is that they can be used in tight spaces and are efficient at dissipating large amounts of heat. One drawback is higher cost and limited Z-direction heat transfer compared to solid metal options.

4. Heat Pipes

Heat pipes are heat spreader devices made from a tubular or flat thermally conductive metal, a wick, and a working fluid. The movement and phase changes of the fluid facilitate the transfer of heat from the heat source to a secondary heat exchanger or ambient air. They are commonly used in electronics and industrial applications. Their primary advantage is that they are best for low-power applications and offer great flexibility when designing a system with many components. Disadvantages include limited performance in extremely high-heat-flux applications and potential orientation issues depending on wick design (though modern sintered wicks mitigate this). Cost varies based on complexity.

5. Composite Heat Spreaders

Composite heat spreaders are made up of multiple materials that work together to remove heat from a primary source. These are usually a thermally conductive metal and a highly thermally conductive material such as boron arsenide or graphite. These heat spreaders are commonly used in electronics with high power demand, where weight is a concern. Composite heat spreaders can effectively and efficiently remove heat without adding too much weight to the device. However, they are more expensive due to complex material integration and niche fabrication processes.

What Are the Applications of Heat Spreaders?

Some of the applications of heat spreaders are listed below:

1. Computer Processors

Heat spreaders are often used in computer processors to prevent them from overheating during operation. The heat spreader is typically mounted directly on the surface of the processor to quickly absorb and distribute heat away from the source. Overheating a processor can lead to permanent damage to the component, reduced lifespan, and decreased performance.

2. Memory Modules

Heat spreaders are used in memory modules (random access memory or RAM stick) to prevent overheating and improve thermal performance and stability. Heat spreaders made of copper or aluminum typically enclose the entire RAM stick due to the confined area that memory modules are placed in.

3. LED Lighting

Large LED floodlights and overhead lights are energy-efficient but still generate lots of heat. Overheating can lead to reduced lifespan and efficacy. LED lights are typically fixed onto a printed circuit board (PCB). These PCBs often integrate aluminum cores or use thermal vias and baseplates to act as spreaders. The heat spreader carries heat to the surrounding air to prevent overheating of the LED components.

4. Power Electronics

Power electronics is the use of electronics to control and convert electrical power. High-power electrical circuits, switches, and components are designed to carry higher currents and generate a lot more heat in the process. Heat spreaders are used in power electronics to prevent overheating, allowing the design of electronics with higher power density, performance, reliability, and service life.

5. Automotive Electronics

As cars become packed with more electronics, the power demand and thus heat generation increase. HVAC, infotainment systems, and dashboard instruments are all electronics commonly included in automobiles. Heat spreaders remove heat from the heat-generating components to prevent overheating and reduce performance.

6. Mobile Devices

Due to the power of today’s mobile devices, heat spreaders are essential to prevent overheating and ensure optimal performance and life. Heat spreaders act as graphite or vapor chamber layers integrated into the structure of the PCB or chassis that powers the device’s functions due to the confined space within a mobile device. Heat is transferred through the heat spreader to the device’s outer shell, and then released into the ambient air through natural convection.

The fluid flow rate and fluid temperature impact a heat spreader’s thermal resistance and its effectiveness at dissipating heat. The smaller the difference between the heat source temperature and the ambient temperature, the more difficult it is for the heat spreader to dissipate heat.

What Are the Factors That Affect a Heat Spreader’s Performance?

The factors that affect heat spreader performance are described below:

1. Thermal Conductivity

Thermal conductivity refers to the ability of a material to conduct heat. Heat spreaders are made of highly conductive materials, such as copper or aluminum. They can quickly absorb and distribute heat away from the heat source. This leads to more efficient cooling. A higher thermal conductivity generally means a more effective heat spreader.

2. Thermal Resistance

Thermal resistance is the resistance to heat transfer across a material or temperature gradient and is considered the inverse of thermal conductivity. While higher thermal resistance within the spreader material is undesirable, system-level thermal resistance (including TIMs and interfaces) primarily affects real-world performance.

3. Surface Area

Heat transfer depends on the movement of energy from a higher-temperature area to a lower-temperature area. As a heat spreader absorbs heat from the main source, it needs to transfer that heat to the secondary heat exchanger or the atmosphere. The larger the surface area of the heat spreader, the more opportunity it has to transfer heat to the environment so that it can continue to absorb more heat from the point source.

4. Heat Sink Design

Heat sink design relates to fin count, fin geometry, and fin placement. More fins can improve thermal dissipation, but only if airflow and spacing are optimized; too many fins can actually trap heat by restricting airflow.

5. Thermal Interface Materials (TIM)

Heat spreaders are attached to components by a TIM. The thermal resistance of a TIM can reduce heat spreader efficiency due to irregularities in the surface of the interface. Voids and trapped air increase thermal resistance and negatively impact heat spreader effectiveness.

6. Airflow

Airflow from fans can improve the effectiveness of heat spreaders. This is because fans can help remove warm air from an electronic enclosure through forced convection. This enhances the temperature gradient and boosts convective heat transfer efficiency.

7. Operating Environment

The fluid flow rate and fluid temperature impact a heat spreader’s thermal resistance and its effectiveness at dissipating heat. Ambient airflow characteristics (velocity, turbulence, direction) and ambient temperature impact thermal dissipation. In environments with poor ventilation or high external temperatures, heat spreader effectiveness drops significantly.

What Are the Benefits of Heat Spreaders?

The benefits of heat spreaders are listed below:

- Preventing Component Damage: Heat spreaders are used to dissipate heat away from electronic components, preventing them from overheating and sustaining permanent damage. This can increase the lifespan of the components and improve the overall reliability of the electronic device.

- Improved Performance: Heat spreaders help improve electronic device performance by preventing overheating. This allows devices to operate within optimal thermal ranges and prevents thermal throttling, which can degrade performance.

- Reduced Energy Consumption: While heat spreaders primarily prevent performance degradation, they do not significantly reduce the total energy consumption of electronic devices. However, they may reduce the energy needed for additional active cooling systems.

- Safety: Heat spreaders contribute to safer products by preventing overheating. This minimizes the potential for burns caused by touching hot surfaces or even fires.

- Flexible Design: Heat spreaders come in various types and can be tailored in shape, material, and configuration. Therefore, engineers have the freedom to design heat spreaders tailored for specific devices to achieve optimal heat dissipation.

What Are the Limitations of Heat Spreaders?

Some of the limitations of heat spreaders are listed below:

- Cost: Heat spreaders can be expensive, particularly those made from high-conductivity materials like copper or advanced composites. Aluminum is generally considered low-cost. This can increase the overall cost of electronic devices.

- Size and Weight: Heat spreaders can increase the weight of electronic devices. Additionally, since many devices are becoming more compact, heat spreaders cannot always remove enough heat from the device.

- Limited Heat Dissipation: The ability of a heat spreader to adequately dissipate heat is limited by the size of the enclosure it serves, the materials and design of the heat spreader, and the ambient conditions to which it must transfer its heat.

- Foreign Debris Can Affect Performance: Dust and debris primarily affect active cooling components like heatsinks and fans. Passive heat spreaders (e.g., vapor chambers inside sealed devices) are typically unaffected unless airflow over attached heatsinks is obstructed.

- Structural Limitations: Heat spreader performance is constrained by the form factor limitations of the device. Therefore, it can sometimes be difficult to design effective heat spreaders if there is limited space within a device.

Frequently Asked Questions About Heat Spreaders

Are Heat Spreaders on RAM Necessary?

Heat spreaders on RAM are not strictly necessary for standard consumer-grade systems, but they can be beneficial in high-performance or overclocked setups. Modern RAM can generate significant heat under high load or when overclocked, and thermal throttling or instability can occur without adequate cooling.

What Is the Difference Between Heat Spreaders and Heat Sinks?

A heat spreader is a device that laterally distributes heat away from a concentrated source, typically to reduce localized hotspots and improve overall heat dissipation efficiency.

A heat sink is a passive heat exchanger that increases surface area to dissipate heat to the surrounding environment, usually through convection (with or without forced airflow).

While they work toward the same thermal goal, a heat sink and a heat spreader serve different functions: Heat spreaders distribute heat, while heat sinks expel it. A heat sink is not a subset of a heat spreader; they’re complementary but distinct.

Summary

This article presented heat spreaders, explained what they are, and discussed their components and applications. To learn more about heat spreaders, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.