Bulk modulus is a measure of a material’s resistance to uniform compression. It describes how much a material decreases in volume when pressure is applied equally in all directions. This property is relevant to gases, liquids, and solids, and it helps assess how materials behave under hydrostatic or confined stress. In a typical measurement, the material is compressed in a way that prevents it from expanding outward. As a result, the pressure is distributed evenly throughout the material’s volume, causing a decrease in volume without a change in shape. This is distinct from uniaxial compression, where deformation occurs in a specific direction. Gases are highly compressible, while liquids and solids are often considered incompressible. In reality, they are simply much harder to compress and require significantly more pressure to achieve noticeable volume reduction.

This article will explain the concept of bulk modulus, describe how it is measured, provide examples of typical values, and outline the benefits of using this property in engineering and design.

What Exactly Is Bulk Modulus?

Bulk modulus measures the change in volume of a material sample, either by compression or extension, as a function of the applied load. For gases, the “tensile” loading is easily applied by using force to increase the volume of the gas in a sealed chamber. For solids and liquids, this is less practical, so the modulus is validated using compressive loading only. The harder-to-perform “tensile” or elastic expansion test has been used to confirm that the bulk modulus in tension is identical to the bulk modulus in compression.

This tension/compression equivalency only breaks down when the elastic limit is exceeded and a yield point is reached. In general, compressive yield (in a volume-constrained part) is considerably higher than the tensile equivalent. Where the part is not effectively volume constrained (i.e., the sample is allowed to bulge perpendicularly to the applied force), the failure mode and yield point are encountered at considerably lower loads, as perpendicular strains are much greater in this squash-necking distortion mode.

How Does Bulk Modulus Work?

Bulk modulus works when the entire load is converted into a pure volume change. A load is applied to a fixed volume of material constrained by shape changes other than compression. In general, the bulk modulus is derived from the single-axis loading of a shape-constrained cylindrical sample in a load cell. Measuring the axial motion of the load application easily converts to a volumetric change, which results solely from the compression.

The applied load is measured in the load cell. The system hysteresis (“taking up of the slack”) is dismissed, and a plot of force against plunger travel distance is produced. In general, the relationship between machine travel (strain) and applied load (stress) is linear to the limits of elastic compressibility, after which yield becomes partially permanent deformation.

What Is the Importance of Bulk Modulus?

Bulk modulus is a critically important measure of a material’s resistance to uniform compression, and it serves as a key indicator of elastic behavior under hydrostatic pressure. For solids such as metals, polymers, ceramics, and 3D-printed components, it is especially valuable in designing systems and structures that must maintain dimensional stability and integrity under pressure. This property is used to predict how materials respond to volumetric stress, including potential density changes under load. It also provides insight into material stiffness, and in some cases, can help infer bonding strength and atomic packing—offering clues about a material’s underlying structure at the microscopic level.

What Are the Uses of Bulk Modulus?

Bulk modulus is applied in various engineering and scientific contexts to support material selection, design validation, and structural analysis. Its main uses include:

- Supporting material selection by evaluating how well a material can resist volumetric deformation under pressure, especially in applications involving fluid containment, pressure vessels, or sealed systems.

- Ensuring that stressed components exhibit sufficient elastic response under compressive loads, maintaining dimensional stability without exceeding deformation limits.

- Assisting in the design of geometries that constrain deformation, allowing better utilization of a material’s volumetric elasticity. This can help reduce the risk of failure modes such as bursting or necking in pressurized or axially loaded parts.

- Providing insight into the crystalline structure of materials, as the bulk modulus is influenced by atomic bonding strength and packing density. This can help in materials research or in verifying material consistency.

How Important Is Bulk Modulus in 3D Printing?

The relevance of bulk modulus in 3D printing depends heavily on the printing method and the resulting internal structure of the part. In many cases, the mechanical behavior of 3D-printed components is influenced more by print architecture than by the bulk properties of the base material. For instance, most 3D-printed parts are made using Fused Deposition Modeling (FDM), which produces parts with inherent porosity and anisotropic characteristics. Even at high infill densities, small voids and incomplete bonding create a structure that behaves more like a porous assembly than a fully dense solid. As a result, the bulk modulus of such prints reflects structural behavior, not just the intrinsic material stiffness.

Bulk modulus can be a meaningful measure in 3D printing methods that yield low porosity and high isotropy, such as:

- Material Jetting, where liquid photopolymers are deposited and cured in layers. The process results in minimal porosity, and the printed parts are relatively homogeneous and isotropic.

- Powder-bed metal printing with complete sintering, such as Metal X or binder jetting with post-sintering, where most voids are eliminated during densification. The final part approaches the properties of fully dense metal, allowing for reliable bulk modulus assessment.

- Selective Laser Sintering (SLS) of plastics, which produces parts with relatively low porosity and consistent mechanical behavior across all directions, making bulk modulus measurements more representative.

For more information, see our guide on 3D Printing.

Bulk modulus provides insight into how materials behave under uniform pressure and is valuable in applications where dimensional stability is critical. Quantifying resistance to volumetric compression helps in selecting suitable materials for pressurized systems, structural components, and fluid containment. While real-world conditions often introduce complexities like bulging or shear that limit direct application, bulk modulus remains an important comparative measure of stiffness and compressibility across gases, liquids, and solids. Understanding this property helps engineers design safer and more efficient systems that perform reliably under varying loads and pressures.

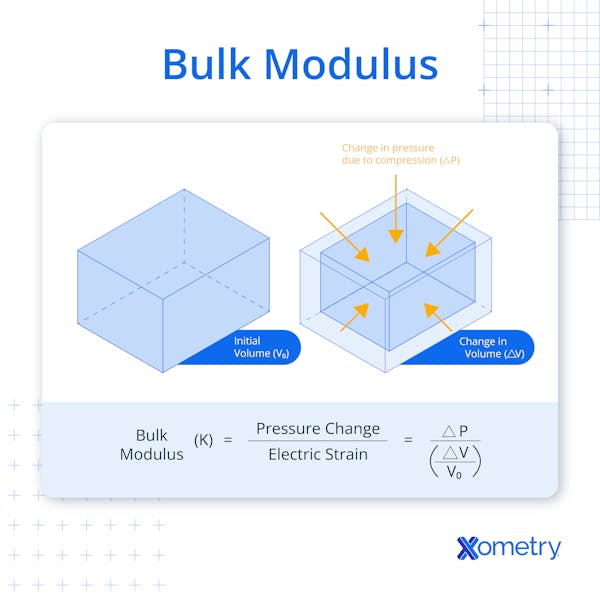

What Is the Formula of Bulk Modulus?

The bulk modulus (K or B) quantifies a material's resistance to uniform compression and is defined as the ratio of applied pressure to the resulting volume strain. It expresses how much pressure is needed to cause a given relative decrease in volume:

K = P / ε (Pascals)

Where:

P = Applied Pressure (Pa)

ε = Volume strain (dimensionless)

K = Bulk modulus (Pa, MPa, or GPa)

Volume strain is dimensionless and represents the fractional reduction in volume under pressure. It is denoted as:

ε = (Vo - Vc) / Vo

Where:

V₀ = Original volume

Vc = Compressed volume

This formula assumes elastic behavior under small volumetric deformations. Alternative methods or corrections may be needed in cases of larger deformation or non-isotropic materials, including using finite strain models or measuring under different boundary conditions.

What Is the Bulk Modulus K?

The bulk modulus is commonly denoted as K in scientific and engineering contexts. It represents a material's resistance to uniform compression and is expressed in units of pressure (Pa, MPa, or GPa). While K is the most frequently used symbol, it can be contextually ambiguous, as it is also used to denote other unrelated constants (e.g., thermal conductivity in some fields).

What is the Bulk Modulus B?

The bulk modulus is also sometimes denoted as B, particularly in physics literature. Although less commonly used than K, this notation serves the same purpose. Like K, the symbol B may be confused with other constants, such as magnetic flux density or bulk strain energy, depending on the field.

How to Calculate Bulk Modulus?

For a typical polyurethane sample, to illustrate the calculation:

- Pressure applied P = 12 MPa

- Volume strain ε = 0.75

K = P / ε = (12 x 106) / 0.75 = 16 MPa

What Is the Unit of a Bulk Modulus?

The unit of bulk modulus is pressure, typically expressed in pascals (Pa) in the SI system. For practical use in engineering, it is more commonly reported in megapascals (MPa) or gigapascals (GPa), depending on the magnitude of the material's stiffness.

What Is an Example of the Bulk Modulus of a Material?

The bulk modulus of steel is around 140 GPa or 2.03 x 107 psi.

What Are the Benefits of Bulk Modulus?

The primary benefit of understanding the relative bulk moduli of materials is that it helps in product design, materials selection, and design for load tolerance and factor of safety issues.

What Are the Limitations of Bulk Modulus?

The limitation of the bulk modulus is that it is not a tangible or real-world meaningful measure, so it is most useful for comparisons of materials. Variations in real behavior are significant, compared with rigorous laboratory testing of the bulk modulus. This is because real-world parts are rarely as perfectly shape-constrained as in bulk modulus testing. Bulging and shear can often distort the apparent bulk elastic behavior, as parts change shape under load.

What Is the Bulk Modulus of a Polymer?

Polymers exhibit a wide range of bulk modulus values, both within and between polymer families. This variation is influenced by molecular structure, crystallinity, crosslinking, and processing conditions. Interestingly, butadiene rubber shows one of the highest bulk modulus values among polymers, despite being highly elastic and easily deformable—an example of how bulk modulus (resistance to volumetric compression) does not directly correlate with perceived softness or flexibility.

For more information, see our guide on Polymer.

Table 1 below shows some examples of the bulk modulus of common polymers:

| Polymer | Bulk Modulus (GPa) |

|---|---|

Polymer PVC (polyvinyl chloride) | Bulk Modulus (GPa) 2.41–4.14 |

Polymer Nylon 66 | Bulk Modulus (GPa) 1.59–3.79 |

Polymer PC (polycarbonate) | Bulk Modulus (GPa) 2.38 |

Polymer PS (polystyrene) | Bulk Modulus (GPa) 2.28–3.28 |

Polymer LDPE (low-density polyethylene) | Bulk Modulus (GPa) 1.08 |

Polymer PET (polyethylene terephthalate) | Bulk Modulus (GPa) 2.76–4.14 |

Polymer PP (polypropylene) | Bulk Modulus (GPa) 1.14–1.55 |

Polymer Butadiene rubber | Bulk Modulus (GPa) 5.5 |

Table Credit: https://www.sonelastic.com/

Frequently Asked Questions About Bulk Modulus

What Is the Bulk Modulus of Water?

The bulk modulus of water is 2.1 GPa or 3.0 x 105 psi.

What Is the Bulk Modulus of Steel?

The bulk modulus of typical steel is around 140 GPa or 2.03 x 10^7 psi.

What Is the Reciprocal of Bulk Modulus?

Bulk modulus for a material defines its resistance to compression. Therefore, the reciprocal of the bulk modulus defines the compressibility of the material.

What Is the Relationship Between Bulk Modulus and Compressibility?

Bulk modulus and compressibility are inverses of each other. Bulk modulus is described as the reciprocal of compressibility. A material that is easily compressed has high compressibility but a low bulk modulus. On the other hand, a material that is difficult to compress has a large bulk modulus but a small compressibility.

Are Bulk Modulus and Volume Elasticity the Same?

Yes, bulk modulus and volume elasticity are the same. Volume elasticity is simply another term for bulk modulus.

What Is the Difference Between Bulk Modulus and Young's Modulus?

Bulk modulus describes the behavior of a material in three dimensions, i.e., the resilience or resistance to volumetric change under load. Young's modulus, on the other hand, is a much narrower and more specific characteristic, in that it defines the tensile elasticity of a material when loaded on a single axis.

Summary

This article presented bulk modulus, explained what it is, and discussed how to calculate it and its importance. To learn more about bulk modulus, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.