We are continually working to enhance the Xometry Instant Quoting Engine®, providing you with greater control over your custom parts. We know that providing clear details upfront is the best way to ensure you get exactly what you ordered, without the headache of delays or quality mismatches. To help you communicate your needs even better, we have added two new customization options for CNC orders: Subprocess Selection and Relaxed Tolerances.

Subprocess selection allows you to specify exactly how you expect your part to be manufactured, ensuring that our team and partners fully understand your intent. The second feature will enable you to opt for wider tolerances when high precision isn't critical, helping you lower the cost of your order. These updates are designed to give you more flexibility to set up your quote your way. Read on to get more details about these changes in the sections below.

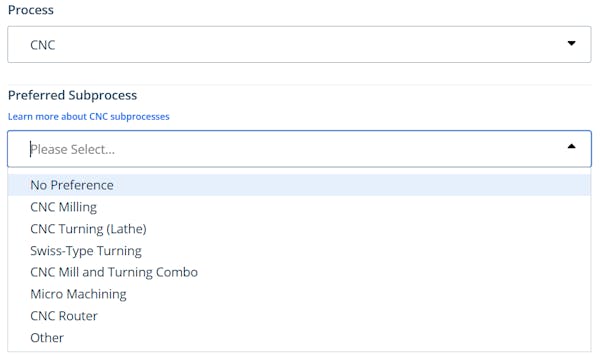

CNC Subprocess Selection in Detail

The "Preferred Subprocess" menu allows you to communicate your manufacturing intent directly to our network. While selecting "No Preference" is typically the most efficient route, this option allows you to inform our manufacturing facilities of a specific machining preference, aligning the production strategy with your vision.

To help you identify the best match for your part's geometry and features, here is a quick guide to the available sub-process options:

CNC Milling

This process uses a rotating cutting tool on a stationary workpiece to remove material, typically across 3, 4, or 5 axes.

- Best suited for prismatic (block-like) parts and complex components requiring features on multiple faces, such as pockets, slots, holes, or intricate contours.

- Select this subprocess if cylindrical features are not the dominant characteristic of the part.

CNC Turning

With turning, the workpiece spins rapidly while a stationary cutting tool removes material, commonly known as lathe work.

- Excellent for parts with rotational symmetry, such as shafts, pins, bushings, fasteners, and simple cylindrical profiles. It is also used to create threaded cylindrical components such as custom bolts or screws.

- Choose this subprocess for the quick production of symmetrical cylindrical parts.

CNC Mill and Turn Combo

This is a combination of both rotational turning and milling, either on a single multi-tasking machine or by transferring the part between machines.

- For complex parts that require both turning (cylindrical features) and milling (flats, cross-holes, or pockets) on the same component.

- Use this for components with shafts or spindles featuring keyways, gear teeth, off-axis holes, or hex features milled onto a round body.

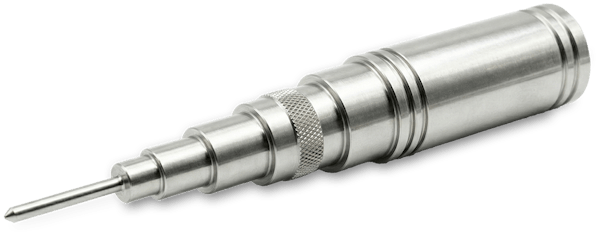

Swiss-Type Turning

This is a specialized turning method where the bar stock slides through a guide bushing while the cutting tool remains stationary. Because the material is supported right at the point of the cut, it eliminates the vibration and deflection common in standard turning.

- Best for long, slender parts with high length-to-diameter ratios (like needle valves, long pins, or shafts) that would bend on a standard lathe.

- Ideal for high-volume production of small, intricate components (typically under 1.25" diameter) requiring extreme precision.

Micro Machining

Micro machining utilizes specialized machines with high-speed spindles and extremely small tools to achieve micron-level tolerances. As the name implies, this process is meant for tiny parts.

- Often used for medical, aerospace, or electronics components (e.g., surgical instruments, fuel injectors, or micro-gears).

- Select this if your part has sub-millimeter features and requires tolerances tighter than ±0.001".

CNC Routing

A high-efficiency subtractive process using gantry-style machines to cut parts from sheet and plate materials. Unlike milling, it preserves the original top and bottom surfaces of the stock material.

- Useful for cost-effective industrial components, such as aluminum tooling plates, where the factory thickness and finish are acceptable.

- It is also ideal for large, flat parts that would be too costly to mill and multi-layer materials where depth control is needed to reveal contrasting internal colors.

Pro Tip: If you are unsure which subprocess is best, stick with "No Preference." We source the manufacturing facilities best suited for your part's geometry. The facility will use its core competencies to produce your part efficiently.

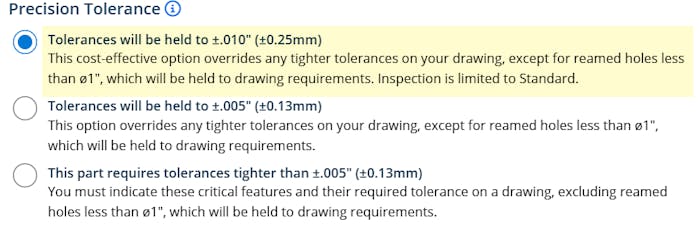

Save With Relaxed Tolerances

Just as specifying a subprocess helps align the manufacturing method with your needs, our new tolerance options help you align precision with your budget. Previously, the Xometry Instant Quoting Engine® allowed you to stick with our standard tolerances or request tighter specifications for critical features. We have now expanded the tolerance dropdown menu with a new option for parts with more forgiving tolerance requirements.

This update enables you to balance your precision requirements with your budget better. If you are ordering early-stage prototypes, cosmetic components, or parts where a tight fit isn't functionally required, selecting the relaxed option allows you to widen the manufacturing window in exchange for a price reduction.

Here is how the three tolerance tiers now compare:

- Standard (Default): Xometry’s general tolerance remains unchanged. Unless specified otherwise, parts are machined to ±0.005” for metals and ±0.010” for plastics and composites.

- Relaxed (New): Selecting this option doubles the standard tolerance range (e.g., ±0.010” for metals). This signals that the part requires less rigorous inspection or machining precision, resulting in a lower cost.

- Tighter: As before, specific tolerances as tight as ±0.001” will automatically quote, and sub ±0.001" requirements can be manually requested for engineering review.

Manufacturing With Xometry

Xometry’s platform is designed to eliminate the friction in sourcing custom parts, transforming a complex supply chain into a simple and intuitive digital experience. Our goal is to give you the tools to specify exactly what you need, whether that means fine-tuning your budget with flexible tolerance options or defining the manufacturing method that aligns with your design. By putting these controls directly in your hands, we make it faster and easier than ever to turn your digital files into physical parts. Visit the Xometry Instant Quoting Engine® to see how easy it is to customize an instant quote for your CNC parts.