Smart Products Are Changing the World: CNC Machining Makes it Possible

We live in a world machined. While most people go about their daily lives never considering CNC machining and all the ways it’s transformed life and work on this planet, here, at Xometry, we think about it constantly.

We live in a world machined. While most people go about their daily lives never considering CNC machining and all the ways it’s transformed life and work on this planet, here at Xometry, we think about it constantly. Being able to see and facilitate the making of so many fascinating parts long before they reach their destination inside a final product is a gift. CNC machining, design, prototyping, assembly — we can hardly get enough of it or of the companies and people who make it happen.

While many of our most faithful customers found out about Xometry on their own — through search engines, online ads or attendance at industry trade-shows like IMTS — we also actively seek out customers we’d like to work with. Whenever we come across inventions, designs or products we enjoy, we work extra hard to find out whether or not Xometry could play a part in making them hum.

In many ways, it’s a habit of the business we’re in. With a CNC machining service network that stretches from sea to shining sea and boasts hundreds of thousands of available hours on thousands of manufacturing’s most advanced machines, wouldn’t you do the same? If you could make anything, what would you make?

Why We Get in There

We heavily scrutinize the latest technology, and we track trends across a wide variety of industries. We do this analysis because we want to understand how things are put together and how everyday products come into existence. Doing so also helps us seek out potential manufacturing work, which is why we take proactive methods.

We print out and clearly highlight CNC machined parts within product teardowns. We unfold exploded axonometric drawings within product assembly instructions. We even bring in our own trending household gadgets to dismantle, and yes — all this activity is commonplace within our Xometry offices in Lexington, KY; Bethesda, MD; and Gaithersburg, MD.

Quest for Fire, Quest for Knowledge

What we do get the chance to dismantle, however, is still very inspiring. Uncovering the gritty, mundane components seamlessly integrated inside everyday objects like fire extinguishers is often mind-blowing. While we hope to never need to utilize one, your average fire extinguisher is an amazing example of a simple yet powerful design that also happens to make excellent use of CNC machining.

Fire extinguishers contain several machinable threaded nozzles and valves. (Check out this well-composed fire extinguisher teardown by Todd McLellan to see what we mean.) The simplicity of these components doesn’t just make for clear-cut CNC machining, it also explains their ubiquity. Fire extinguishers are found mounted to walls in nearly every building — often times throughout multiple units within larger building complexes — in the entire world. Yes, they’re useful, but their design makes for easy production scalability, too.

Journey to the Amazon

We can go further. Here’s a question meant to peel back the layers of manufacturing even further:

“Alexa, what parts of you use CNC machining technologies?!”

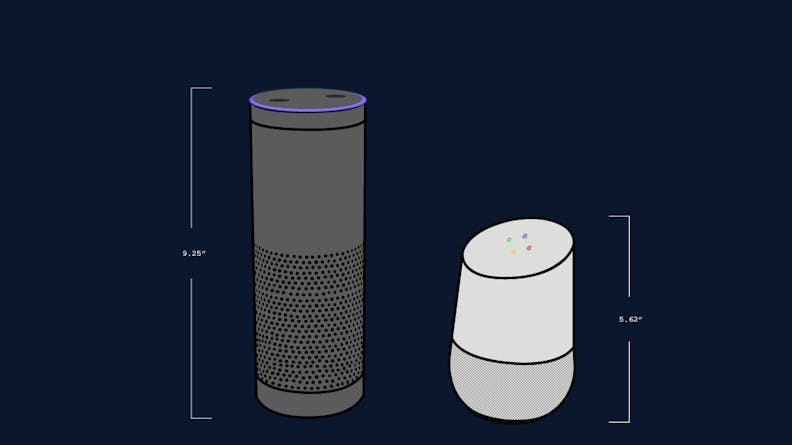

While the Amazon Echo Dot has a plastic encasement and internal components that are produced with and injection molding service, the inverse dies used to form the plastic components are generated from CNC-milled solid aluminum billets. That goes for the Google Home as well. In other words, it doesn’t matter which smart home assistant device’s jokes you prefer or which one’s methods for queuing up your favorite playlist feel most intuitive. Each one utilizes CNC machining in its manufacturing process.

As you can imagine, uncovering that truth excites us, because Xometry is literally in the business of accelerating the CNC manufacturing process. By leveraging our vast and vetted CNC machining capacity available all over the country and by using our advanced data-driven cloud technologies, getting to market with amazing new things wouldn’t just happen for companies like Amazon and Google. It would happen faster.

Intelligent Designs

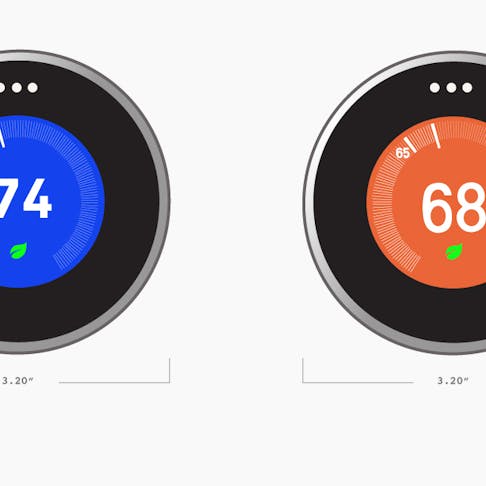

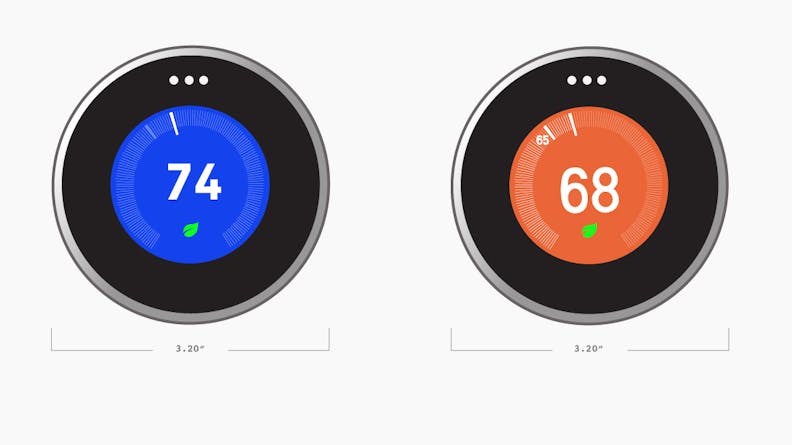

Another example of CNC machining inside a haptic object like those discussed above is the solid stainless steel ring that encases the omnipresent Nest. A smart-thermostat for the home, its final 3.27” diameter is likely turned down on a lathe from a 3.375” diameter solid rod stock of 316 Stainless Steel. The smooth aesthetic for the outside of the ring was likely handled in a fine finish pass with a minimal depth of cut right at the CNC lathe, too. Our trusted network of manufacturing partners know the optimal feed and speed rates to make components like this one and numerous others.

While we know these devices sound like the next tech-driven antagonists at the center of movies like Kubrick’s 2001: A Space Odyssey and Disney’s mildly dystopian Smart House, we’re not in the least bit apprehensive. Setting the temperature of your living room from your phone before leaving the office is actually quite convenient.

Prone to volatile and rapidly changing weather, what’s happening outside is just about the only downside to living here. We are actually really lucky to live here in the heart of American manufacturing. When it comes to seeking out and finding amazing partners who can machine parts on time and at the quality, we’re sitting in the literal sweet spot.

But what about designs whose appearance and use simply cannot be handled at the CNC machine? What about those that require secondary processes for pragmatic reasons like wear resistance, color, structural integrity, etc.? Well, our precision CNC partner network can handle all that, too. From a common Type II black anodize to more specialized zinc plating and heat treating, our network of manufacturing partners and secondary process suppliers can handle secondary finishes to spec and they can do it within prescribed time constraints, too.

Send in the Drones

It gets weirder and more wondrous.

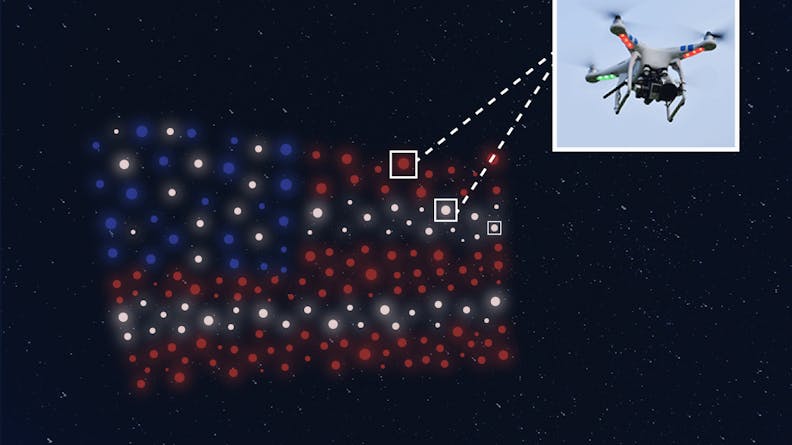

What do flying drones choreographed to “dance” and form an American flag alongside a suspended and singing Lady Gaga have in common with perforated CNC waterjet-cut panels of the brise-soleil on the southernmost facing façade of a recent LEED-certified building? They each contain CAD modeled, CAM programmed, CNC produced components that, when aggregated together, form final forward-thinking networks designed by top engineers and firms and manufactured by highly skilled machinists in U.S. machine shops.

It seems like every day finds us chomping at the bit to take apart another new product. We want to keep learning how things get made, so we can better leverage our network of thousands of partners on behalf of manufacturers. Our machining base can deliver first prototypes all the way through final production runs, and they can do it with the utmost precision, on time and at the quality. For companies in need of components to fill products hitting the shelves just in time for the holiday season, for Tier 1 OEM automotive parts makers supplying some of the world’s most progressive automotive companies with what they need to hit the assembly line, we’re here to ensure procurement is faster and easier, and we love it, too.

Here’s hoping that future books by Apple, such as the one recently released titled Designed by Apple in California, come jam-packed and full of well-composed images and teardowns that chronicle the custom tooling responsible for creating the slots, shallow pockets and reamed holes designed to house keys with symbols, hardware and other critical components that, when combined, enable the functionality and aesthetic that enamor so many of us. While that kind of documentation may take some of the mystery out of objects, to us, it only further stokes our curiosity and encourages us to wonder:

What will we get to make next?

To find out more about how Xometry can meet your manufacturing needs, click here.