Which 3D printed plastics are the toughest? In this "Will it..." video, Greg Paulsen, Xometry's Director of Application Engineering, 3D printed the popular "3D Bency" using a number of different materials (polycarbonate, PLA, polypropylene, ULTEM, Nylon 11 and 12, etc.) and processes (FDM, SLS, MJF, SLA, LSPc, Polyjet, DLS, etc), then ran several abrasion tests on them.

Watch to find out which 3D printed plastic is truly the toughest of them all!

More About This Test

We performed this test with the popular "3D Benchy", a 3D model specifically designed for testing and benchmarking 3D printers. In this first part of the series, we tested the abrasion resistance of various materials ranging from thermoplastics to photopolymer resins by media blasting them with an aggressive aluminum-oxide media. Here is a list of the processes and materials we tested:

Fused Deposition Modeling (FDM)

- PLA

- Polycarbonate

- ULTEM 9085

Selective Laser Sintering (SLS)

- Nylon 12 (dyed blue)

- Nylon 11 EX

- Polypropylene

- TPU 88A

- Accura ClearVue (quick-clear finish)

- Somos EvoLVe 128

Lubricant Sublayer Photo-curing (LSPc)

- xCE

- xPP405

- RPU 70

- Opaque Rigid Photopolymer

Test Results & Observations

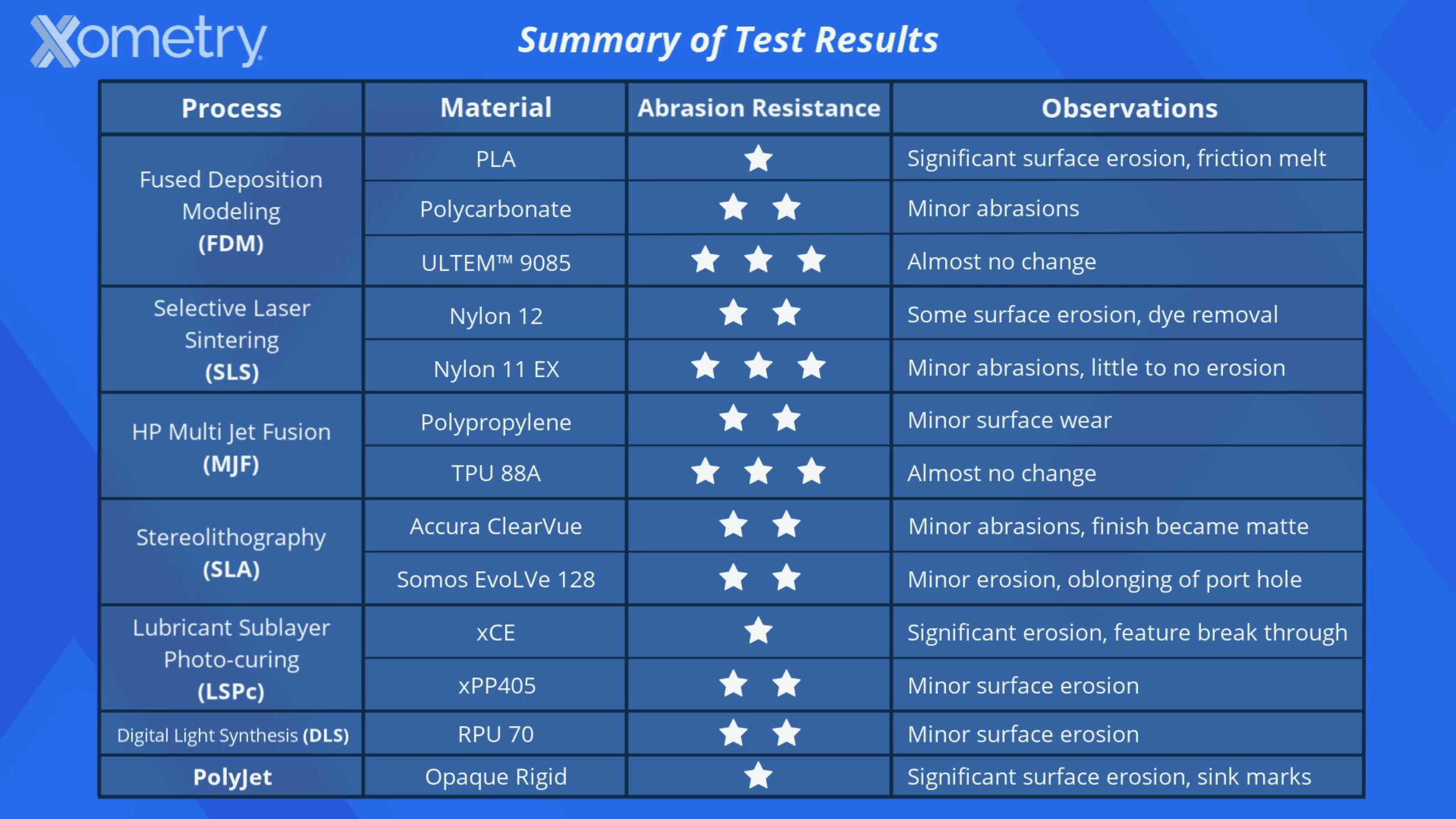

At the conclusion of the media blasting abrasion tests, we assigned an abrasion resistance ranking to each material based on how it performed. 1-star rated materials exhibited poor abrasion resistance, exemplified by issues such as surface erosion, feature loss, abrasions, etc. In contrast, 3-star rated materials had excellent abrasion resistance and held up significantly better.

You can see the results from the test in the chart below:

Results summary from media blast abrasion test

FDM - Red PLA