Polyphthalamide (PPA) is a semi-crystalline thermoplastic used mainly in the automotive and electrical industries, with additional applications in consumer goods and industrial equipment. Its moisture and temperature resistance make it an ideal material for these sectors.

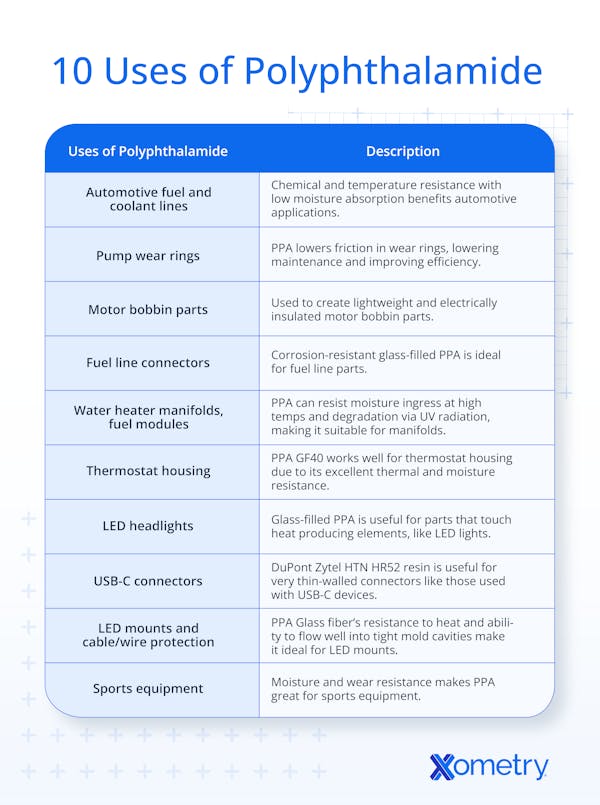

Polyphthalamide has excellent moldability, which makes it well-suited for injection-molded components with intricate features and thin sidewalls. This article will describe 10 uses of Polyphthalamide – as summarized in the table below – and give reasons why this material works so well.

1. Automotive Fuel and Coolant Lines

Automotive fuel lines and coolant lines are the arteries of any combustion engine. However, they carry corrosive chemicals and function in hot environments. Compared with conventional aliphatic nylons, PPA’s chemical resistance and lower moisture uptake improve dimensional stability and can reduce fuel permeation in under-hood applications. Automotive designers, who continuously strive for improved efficiency and fewer emissions, will appreciate this side effect.

2. Pump Wear Rings

Various pumps are designed to transport fluids ranging from water to hydrocarbons. They often run under high pressure, high temperatures, and corrosive conditions. Pumps in challenging applications are usually made from corrosion-resistant stainless steel or are lined internally with corrosion-resistant coatings. Pump wear rings are not seals. They are close-clearance components that limit internal recirculation between high- and low-pressure regions in the pump, improving efficiency. Clearances are set per standards such as API 610 rather than by compression against rotating parts. They are also designed to be replaced as the continuous contact with moving parts creates significant wear. PPA wear rings can lower friction and help stabilize the rotor, which can improve efficiency and reduce vibration when clearances are properly maintained. The creep resistance of PPA means that the wear rings will maintain their shape over time.

3. Motor Bobbin Parts

A motor bobbin is a component over which the copper coils of an electric motor are wrapped. These bobbins were traditionally made from metal, so they added a lot of weight to electric motors. However, electric motors with PPA motor bobbins are significantly lighter. Reducing motor mass can contribute to efficiency and range in electric vehicles, although the effect from bobbin substitution alone is modest compared to larger mass drivers. Because PPA has excellent moldability, bobbin wall thickness can be easily optimized. PPA material is also an excellent electrical insulator.

4. Fuel Line Connectors

Fuel line connectors are used to connect flexible fuel lines to equipment like fuel pumps and fuel filters. These couplings need to be able to survive the corrosive fuel while also resisting the high temperatures in which they operate. Glass fiber-reinforced grades such as PPA GF33 or GF35 provide the necessary chemical and thermal resistance.

5. Water Heater Manifolds, Fuel Modules

Solar water heaters work by running water through a series of pipes that absorb heat from the sun. They reduce loads on electrical or gas-powered water heaters and therefore save energy. The manifold is the component that connects the pipes to the tank. It must resist hot-water exposure and moisture ingress. For UV-exposed parts, PPA typically requires UV-stabilized grades or shielding; with appropriate stabilization, PPA can be used for manifold components.

The fuel module is an automotive component that controls the extraction and metering of fuel from the fuel tank. In short, it regulates the fuel flow rate. The fuel module needs to resist corrosive chemicals, so PPA’s chemical resistance makes it ideal.

Every material choice is a balance between properties and practicality. Polyphthalamide stands out because it combines the toughness of traditional nylons with the stability required for precision applications.

6. Thermostat Housing

A vehicle’s thermostat is usually situated on the engine block and also functions as the engine coolant exit. The thermostat prevents coolant from flowing until the engine itself has warmed up. Once the coolant is moving, the thermostat helps to regulate the engine’s temperature. Because the thermostat housing is located on the hot engine block and is exposed to hot coolant, it needs to have excellent thermal and moisture resistance. Glass fiber-reinforced grades such as PPA GF40 provide the required heat and moisture resistance.

7. LED Headlights

Most new vehicles use LED headlamps due to their efficiency, longevity, and luminosity, but adoption is not universal. An LED headlamp consists of a lamp housing, lamp bezel, module frame, and reflector. The lamp module frame comes into direct contact with the LED lights, so it needs to be heat-resistant. It is also advantageous for the module to be lightweight. Glass fiber-reinforced PPA combines high thermal resistance with good flow characteristics for molding.

8. USB-C Connectors

USB-C connectors are fast becoming the standard data and power ports for mobile phones and laptops. By design, USB-C connectors are very small and feature walls as thin as 0.18 mm. To injection-mold parts with such thin walls, a specialized PPA is used, specifically DuPont Zytel HTN HR52, a grade formulated to enhance PPA’s moldability for ultra-thin walls.

9. LED Mounts and Cable/Wire Protection

LED mounts are just what they sound like; the LEDs and associated circuit boards get affixed to a molded mounting unit so they can be properly fitted in devices or lighting sconces. While LED lights generate far less heat than incandescent bulbs, they still warm up. The LED mounts need to be able to withstand this heat without degrading. Glass fiber-reinforced PPA is ideal for this application because of its heat resistance. Because PPA flows well in the melt state, the mounts can be designed as very thin parts that use minimal material. These features also make PPA ideal for cable or wire protective fittings and couplings.

10. Sports Equipment

Sports equipment is often exposed to moisture. Track equipment, cycling gear, and watersports equipment, among others, routinely get wet. As such, equipment must be made of a material that resists moisture ingress even during long-term outdoor use. PPA is well-suited because it resists water absorption and maintains durability over time. PPA is used in some sporting goods that see moisture and repetitive loading, but usage varies by product category.

Frequently Asked Questions About Polyphthalamide

What is the Importance of Using Polyphthalamide?

Polyphthalamide (PPA) is an advanced semi-crystalline thermoplastic valued for its temperature resistance, moldability, chemical resistance, and mechanical strength. It is widely used in automotive fuel system components because of its relatively low fuel permeation compared to standard nylons, and it performs well in heat- and moisture-intensive environments.

What Are the Risks of Using Polyphthalamide?

Polyphthalamide, like most engineering thermoplastics, is non-toxic when used in its intended applications. If burnt, PPA can release toxic combustion products that are harmful to human health. PPA is not typically used in medical and food applications and therefore does not pose a health risk to normal consumers if used as intended.

When Was the First Time Polyphthalamide was Used?

Polyamides such as Nylon 6,6 were first developed in 1935 by DuPont. Polyphthalamides (PPA), which incorporate aromatic units for higher thermal resistance, were commercialized decades later, with wider adoption beginning in the 1980s.

Which Products Contains the Most Polyphthalamide?

Automotive components account for the largest share of PPA use, followed by electrical and electronics applications; aerospace use is more limited. Its combination of moisture resistance, thermal stability, mechanical strength, low permeability, and rigidity makes it highly versatile.

Is Using a Machine Necessary When Using Polyphthalamide?

Specialized equipment is required to process Polyphthalamide. It is typically shaped using melt processing techniques such as injection molding or extrusion, and finished parts may also be CNC machined.

Summary

This article provided a look at the versatility of Polyphthalamide and summarized 10 important uses of the material.

Xometry offers injection molding services for all of your prototyping and production needs. Visit our website to learn more and to request a free, no-obligation quote using our Instant Quote Engine.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.