Face milling and peripheral milling have fundamental distinctions and applications in precision machining. Each of these methods has specific benefits and applications, and they are essential in many different fields, including manufacturing and metalworking. In peripheral milling, the cutter is oriented parallel to the surface of the workpiece. In contrast, face milling involves positioning the tool perpendicular to the surface, with cutting occurring primarily on the tool face.

Choosing the best strategy for a given operation, maximizing efficiency, and attaining desired results all depend on understanding the differences between these two approaches.

This article will examine the main differences between face milling and peripheral milling based on each technique's advantages and best applications.

What Is Face Milling in Machining?

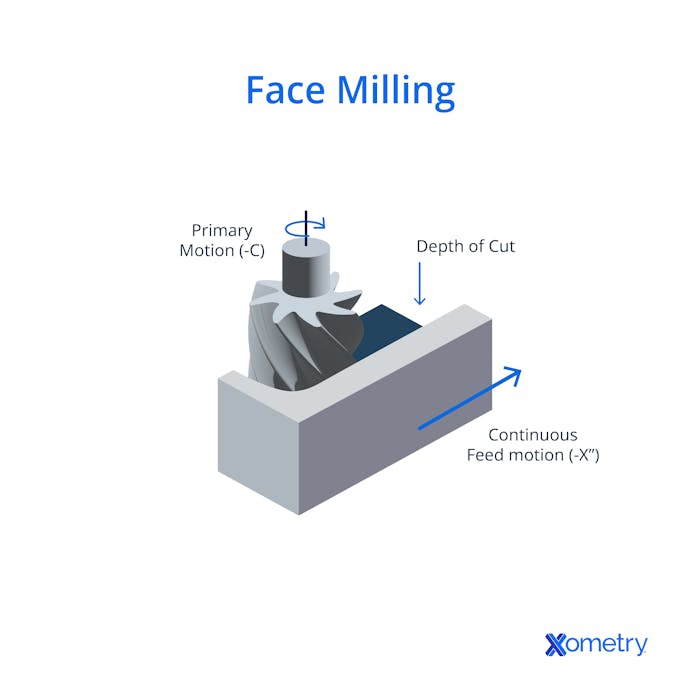

Face milling is a specialized CNC milling process used to remove excess material from a workpiece using cutting tools. It is distinct from peripheral milling due to the orientation of the cutting edges relative to the workpiece surface. In face milling, the tool's rotational axis is perpendicular to the surface of the workpiece, and cutting occurs primarily with the face of the tool. For fields in which flat, smooth surfaces are vital, this approach is widely used.

How Does Face Milling Work?

Face milling is a precision machining operation typically involving setup, tool positioning, parameter adjustment, and material removal. To prevent any slippage during machining, the workpiece is firmly fastened to the machine table. The milling cutter is positioned with its rotational axis perpendicular to the workpiece surface, typically using a face mill rather than a fly cutter in modern CNC applications. If required, the proposed movement of the cutting tool is then fine-tuned by changing the feed rate and spindle speed. Finally, machining starts under the guidance of a CNC program, assuring accurate and consistent material removal and workpiece shape.

What Is the Purpose of Face Milling?

The purpose of face milling is to create a flat surface on the workpiece, achieved by cutting with the ends of the cutter rather than the sides. This process is essential for achieving precise, flat, and smooth surfaces on materials, such as plates or bars. Face mills often have a diameter larger than the step-over width (not necessarily the full workpiece), allowing efficient surface coverage and material removal.

What Is Face Milling Used For?

Face milling serves as a versatile machining process with diverse applications. It levels surfaces, formats workpieces, and incorporates features like hole patterns and recesses. Edge processing is another key function. While planers can handle very large workpieces, face milling is more common and practical for general machining in both small and large workshops. In woodworking, they're essential for crafting items like cutting boards and preparing wood-epoxy resin tabletops for further finishing. These machines can also efficiently drill rows of holes, enhancing their adaptability.

What Is Peripheral Milling in Machining?

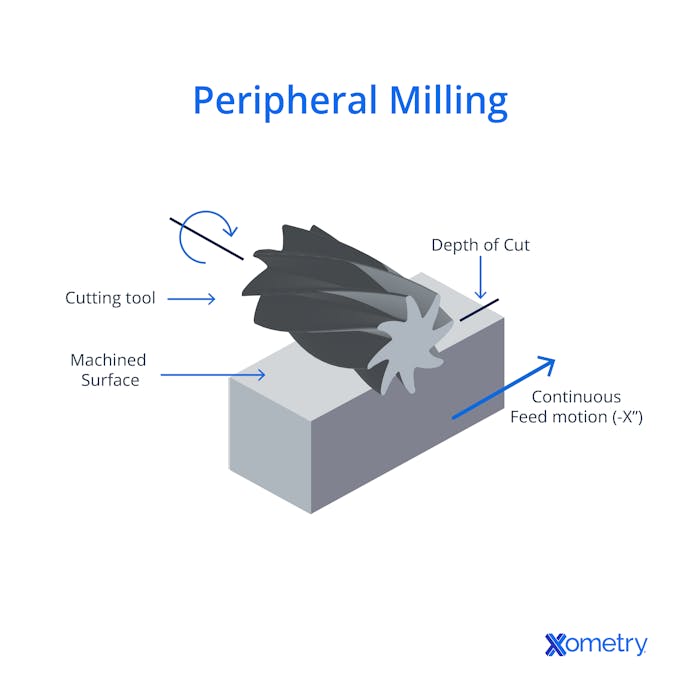

Peripheral milling is a machining process in which the cutting action occurs primarily along the periphery (sides) of the milling cutter, using tools with teeth on the circumference. The workpiece's surface is kept parallel to the cutter's axis by performing this operation on a horizontal spindle machine. It is a procedure made to effectively remove material from a workpiece's exterior, enabling precision contouring and shaping. It is essential in industries that demand detailed and precise workpiece profiles.

How Does Peripheral Milling Work?

Peripheral milling is a machining process that removes material from the outer surfaces of a workpiece using the side edges of a rotating cutter. The process typically begins with securing the workpiece to the machine table and aligning it for lateral engagement with the rotating cutter. A suitable side-cutting tool, such as a slab mill, helical cutter, or staggered tooth cutter, is selected and positioned to cut along the length or side of the workpiece. As the cutter rotates, it removes material from the workpiece's periphery, allowing for accurate shaping. This method is ideal for external surface machining, especially for operations like contouring, slotting, and shoulder milling. Quality checks are performed to ensure the workpiece meets the required specifications.

What Is the Purpose of Peripheral Milling?

The main purpose of peripheral milling is to remove material efficiently from the sides or outer surfaces of a workpiece. This effectiveness comes from using the cutter's sides rather than its tip, which enables faster material removal rates. Peripheral milling uses the full length of the cutting edges along the side of the tool, whereas face milling primarily engages the tool’s end or face. It is the best option for applications requiring quick material removal and productivity benefits.

What Is Peripheral Milling Used For?

Peripheral milling has a broad range of applications, including slabbing operations to cut large material slabs, profile milling for intricate shaping, slotting to create grooves or slots, straddle milling for simultaneous milling on two parallel surfaces, and slitting operations for precision cutting. Moreover, it's used in the milling of facades or slopes and finds a vital role in rough machining, particularly in mold making, in which material removal rates and productivity are essential considerations.

How To Choose Between Face and Peripheral Milling?

Choosing between face and peripheral milling depends on the specific machining requirements. Face milling uses the cutting edges on the bottom face of the tool, typically with multiple inserts arranged radially, which makes it ideal for finishing operations to produce flat, smooth surfaces. For roughing and machining formed surfaces, however, peripheral milling, which relies on cutter teeth near the edge, excels at removing considerable amounts of material. The choice is made based on the finish you want and how much material needs to be removed for your machining operation.

Face milling cuts with the end of the tool and is best for creating flat surfaces, while peripheral milling cuts along the sides and is ideal for deeper or contoured features. The choice between face milling and peripheral milling depends on the part geometry, surface finish needs, and material removal rate required.Kurt PokopacSenior Solutions Engineer

How Does the Main Cutting Direction Differ in Face Milling and Peripheral Milling?

In face milling, the cutting tool is mounted perpendicular to the surface of the workpiece. In contrast, "peripheral milling" involves the cutter moving in a parallel direction to the workpiece's surface, maintaining a parallel alignment to the mill. This distinction is fundamental, impacting the types of cuts and finishes achieved in machining operations, with face milling providing flat surfaces and peripheral milling creating contoured or profiled edges.

How Do Face and Peripheral Milling Differ in Terms of Cutting Depth?

Face milling cutters primarily excel at removing material from the surface of a workpiece to create flat or planar surfaces. The cutting depth is typically quite shallow, often only a fraction of an inch. In contrast, peripheral milling cutters are designed for deeper cuts and can remove material from the edges or perimeters of the workpiece. They are suitable for applications in which greater cutting depths are required.

Do Face and Peripheral Milling Differ in Tool Engagement?

Yes, face and peripheral milling differ in tool engagement. Face milling typically involves full-width engagement, where the entire bottom cutting surface of the tool contacts the workpiece simultaneously. This results in a smoother, more even surface finish since it minimizes tool vibrations and chatter. On the other hand, peripheral milling has partial-width engagement, in which only a portion of the tool's edge contacts the workpiece. This can lead to a less uniform surface finish due to the intermittent contact, which may result in more pronounced tool marks or scalloping.

How Does Face Milling Differ from Peripheral Milling in Surface Finish?

The two unique machining techniques of face milling and peripheral milling take different approaches to producing a surface finish. Face milling produces a finish that is smoother and more consistent because the cutting tool predominantly contacts the flat surface of the workpiece. A less consistent finish may result from changes in how the tool engages the material when peripheral milling, which involves cutting along the edge of the workpiece. Usually, face milling results in a better surface finish.

How Do Face Milling Tools Differ from Peripheral Milling Tools?

Face milling tools and peripheral milling tools are designed differently to suit their respective machining methods. Face milling tools have multiple inserts that engage the workpiece's flat surface, facilitating efficient material removal and a smoother surface finish. Common tools for face milling include face mills and fly cutters. Peripheral milling tools are intended for machining the edges of a workpiece. They typically have fewer inserts and are designed for cutting along the workpiece's periphery. Common peripheral milling tools include end mills and slot drills. These tools are more suitable for contouring and slotting operations.

Does Face Milling Remove Materials Faster Than Peripheral Milling?

No, material removal during face milling is not always faster than during peripheral milling. The speed and effectiveness of the milling process depend on several variables, including the particular application, machine configuration, tools, and workpiece material. While peripheral milling excels at cutting along the periphery of the workpiece and optimizing tool contact, face milling is better suited for producing smooth surface finishes. The particular project should determine which of these methods is best.

Are Face and Peripheral Milling Common Types of Milling in Machining?

Yes, face milling and peripheral milling are standard machine milling techniques. They are commonly used to shape, sculpt, and finish workpieces across a range of industries. While peripheral milling concentrates on the periphery, face milling entails cutting along the workpiece's face. These techniques are fundamental and adaptable, making them crucial in machining processes for tasks like attaining exact profiles on workpieces, generating flat surfaces, and forming holes.

Summary

This article presented face and peripheral milling, explained each process, and highlighted their key differences in application, tool orientation, and surface finish. To learn more about face milling and peripheral milling, contact an Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including machining and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.