How to Read Aluminum Alloys and Tempers

Properties of aluminum materials can vary significantly based on alloy composition and how that alloy is tempered after its creation. Read this article to learn more about aluminum alloys within the standard naming system.

Aluminum is a metal that combines robust mechanical properties with low weight. It is significantly lighter than other metal counterparts, such as steels. Many applications are weight-sensitive, so the use of aluminum in vehicular, aircraft, spaceflight, and equipment designs is very common. Aluminum materials are most often formed from casts or extrusions and are go-to materials for CNC machining and sheet metal parts.

Not all aluminum stock is the same. Properties of aluminum materials can vary significantly based on alloy composition and how that alloy is tempered after its creation. Aluminum alloy is defined using standard naming, this article helps better understand the aluminum alloy designation system.

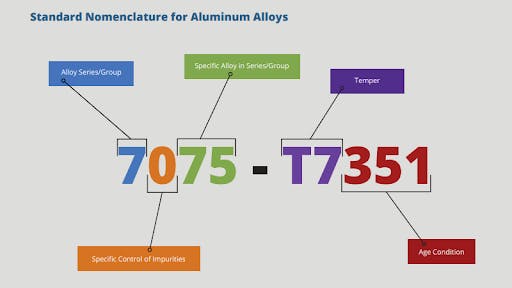

The specification of aluminum alloy can be broken down by its series, temper, and conditions.

An additional suffix after tempers can signify the wrought product type for even more specific material specifications. The example table below shows the classifications for aluminum 7075-T7351.

| Letter Indicator in 7075-T7351 |

|---|

Letter Indicator in 7075-T7351 7XXX-series |

Letter Indicator in 7075-T7351 T7 |

Letter Indicator in 7075-T7351 351 |

A breakdown of what each character in aluminum 7075-T7351 means for that specific alloy.

Understanding Aluminum Series

Aluminum is typically alloyed with other elements to produce different strengths. These alloys are defined by strength in their series, with labels ranging from 1xxx- to 7xxx-series depending on the alloying agents used. The chart below shows different alloy series and what makes them unique.

| Alloy Series | Alloying Agent(s) | Description | Examples |

|---|---|---|---|

Alloy Series 1xxx | Alloying Agent(s) 99%+ Pure Aluminum | Description Is soft, ductile, and easily welds. Is not heat-treatable. | Examples Aluminum 1100 |

Alloy Series 2xxx | Alloying Agent(s) Copper | Description Has high strength and durability and requires corrosion protection. | Examples Aluminum 2024 |

Alloy Series 3xxx | Alloying Agent(s) Manganese | Description Is highly ductile, great for bending, and best suited for forming. | Examples Aluminum 3003 |

Alloy Series 4xxx | Alloying Agent(s) Silicon | Description Has a lower melting point and is used as a welding wire. | Examples Aluminum 4032 |

Alloy Series 5xxx | Alloying Agent(s) Magnesium | Description Has high strength and malleability, is great for bending, and is corrosion-resistant. | Examples Aluminum 5052 |

Alloy Series 6xxx | Alloying Agent(s) Magnesium + Silicon | Description Has high strength and formability. Is weldable, heat-treatable, and corrosion resistant. Has wide range of use across industries. | Examples Aluminum 6061, Aluminum 6063 |

Alloy Series 7xxx | Alloying Agent(s) Zinc | Description Has very high tensile strength and stiffness as well as high usage in aerospace designs. Is not suitable for bending. | Examples Aluminum 7050, |

Wrought aluminum alloy lookup table. 2xxx, 5xxx, 6xxx, and 7xxx-series are the most typical alloys used in aerospace and defense.

The secondary numbers before the temper are specific alloy compositions per aluminum series. 6XXX-series aluminum, like 6061, is very popular because it does not work-harden quickly, allowing greater ease of raw material manufacturing through the extrusion of profiles. This reduces the costs of raw stock material fabrication. The material is also easily CNC milled for custom manufacturing. However, 6061 may be too brittle for rolling or forming. This is why 5XXX-series aluminum, like 5052, is most common in sheet metal fabrication or stamping applications.

An alternative to wrought billets is cast aluminum. This material provides a near-net-shape of the product. MIC-6 is a cast 5083 aluminum that is used for tooling plates and test fixtures.

Understanding Aluminum Tempers

To classify aluminum types beyond the net shape and strength of the alloy, temper is used in the naming series. Tempers add additional mechanical properties through rapid cooling (quenching), cold working, or precipitation heat treatment combinations.

Aluminum and alloys from 1XXX-, 3XXX-, 4XXX-, 5XXX-series can not be heat treated but can be strain hardened. This is signified with a suffix of -H##. Strain hardening strengthens a material through cold working. For example, Aluminum 5052-H32. 2XXX-, 6XXX-, and 7XXX-series aluminum can be precipitation hardened, or heat-treated, signified by a -T#, such as 6061-T6. The following reference chart depicts different aluminum tempers.

| Extrusion Temper | Description |

|---|---|

Extrusion Temper F | Description Extruded, air-cooled with no special controls |

Extrusion Temper O | Description Fully annealed to the lowest strength temper |

Extrusion Temper H1 | Description Strain-hardened |

Extrusion Temper H2 | Description Strain-hardened and partially annealed |

Extrusion Temper H3 | Description Strain-hardened and stabilized |

Extrusion Temper H4 | Description Strain-hardened and lacquered or painted |

Extrusion Temper W | Description Solution heat-treated |

Extrusion Temper T1 | Description Cooled from an elevated temperature and naturally aged |

Extrusion Temper T2 | Description Cooled from an elevated temperature, cold-worked, and naturally aged |

Extrusion Temper T3 | Description Solution heat-treated, cold-worked, and naturally aged |

Extrusion Temper T4 | Description Solution heat-treated and naturally aged |

Extrusion Temper T5 | Description Cooled from an elevated temperature and artificially aged |

Extrusion Temper T6 | Description Solution heat-treated and artificially aged |

Extrusion Temper T7 | Description Solution heat-treated and stabilized |

Extrusion Temper T8 | Description Solution heat-treated, cold-worked, and artificially aged |

Extrusion Temper T9 | Description Solution heat-treated, artificially aged, and cold-worked |

Extrusion Temper T10 | Description Cooled from elevated temperature, cold-worked, and artificially aged |

Extrusion temper lookup chart. Tempers may have multiple digits after a letter to indicate sub-classifications in each temper, material age condition, and final state.

Looking Beyond Aluminum Alloys and Tempers

Beyond tempers, there may be additional suffix classifications that are specific to that series/temper combination. The Metallic Materials Properties Development and Standardization Handbook, MMPDS-14, is a powerful reference for more complete definitions and standards of metals used in manufacturing.

This excerpt was inspired by Xometry’s ebook: Custom Manufacturing for Aerospace and Defense. You can get an instant quote on custom CNC or sheet metal projects here.