Sawmilling is essential for converting raw logs into usable lumber, which meets the demand for processed wood products in the lumber industry. Sawmills, ranging from traditional to modern, facilitate this conversion process. Sawmills produce various lumber products from logs of different tree species.

This article will discuss how sawmilling works, the materials used, and its uses.

What Is Sawmilling?

A sawmill is a facility equipped with machinery for cutting logs into products such as planks and boards. In essence, it is an important phase in the process of using wood. Its transformational function is to turn raw logs into forms that are useful to a variety of industries. This step in the lumber production chain highlights the economic and practical importance of sawmilling to the manufacturing, woodworking, and construction industries.

What Industry Is Sawmilling In?

The forestry and wood processing industries depend heavily on sawmilling. Sawmill operations and procedures are essentially related to the lumber industry. This industry includes planting, harvesting, and processing wood, and sawmilling is a key component in turning raw logs into a variety of lumber products. Sawmilling is a key component of the wood production process and plays a major role in the building, furniture, and other wood-based industries. This emphasizes the importance of sawmilling in satisfying the various demands of these industries.

What Are the Different Types of Sawmills?

The different types of sawmills are listed below:

- Gang Saw: A gang saw consists of multiple straight blades set within a frame that moves up and down. This design enables the simultaneous cutting of several boards from a log or squared beam in one pass through the mill, enhancing efficiency.

- Bandsaw Mill: Bandsaw mills utilize a continuous band of toothed metal stretched between two or more wheels. This design allows for uniform cutting action and the ability to cut irregular or curved shapes, making the cutting process accurate and efficient.

- Sash Sawmill: The sash sawmill is characterized by a single straight blade that moves vertically inside a wooden sash. It was formerly known as an English gate sawmill or frame sawmill, and it employed straight blades called mill saws or long saws.

- Muley Saw: A muley saw operates similarly to an up-down sawmill but lacks a frame. The straight saw blade moves vertically between wooden guides. The term "muley" may derive from the German "mühl-sage" (mill-saw). These blades are typically made of heavier gauge steel compared to those used in sash sawmills.

- Pit Saw: Historically, a pit saw involved two sawyers manually converting logs into boards. One stood above the log, while the other worked in a pit below, pulling a long two-handled saw (whipsaw) through the timber. Although not a sawmill per se, this method was a precursor to mechanized sawmilling.

- Circular Sawmill: A circular sawmill uses a rotating disk-shaped blade with teeth along its edge, offering a more modern approach to cutting lumber.

How Does a Sawmill Operate?

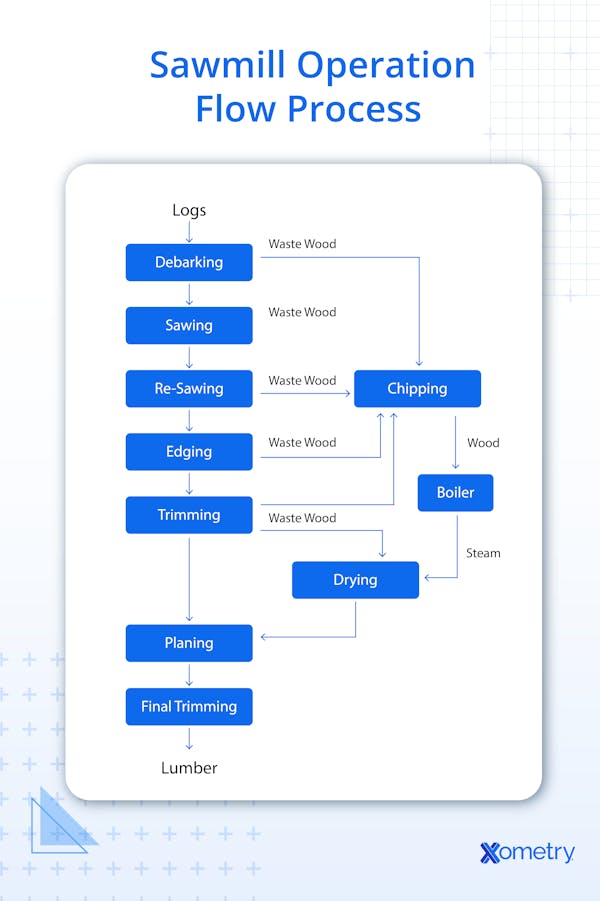

A sawmill operates through a systematic process, as illustrated in a sawmill process flow diagram in Figure 1 below:

The process begins with debarking, followed by primary sawing to produce cants and flitches, then resawing, edging, trimming, drying, and planing. The final trimming ensures precise dimensions, yielding lumber. Waste wood is repurposed into products like wood chips, mulch, or fuel for drying kilns and boilers. Chipped wood can be used in boilers to generate steam, which powers drying kilns or mill equipment. This cyclical and efficient workflow maximizes resource utilization and minimizes waste. The integration of various stages, from log processing to energy generation, characterizes the comprehensive and sustainable nature of sawmill operations.

How Is Sawmilling Different From Side Milling in Terms of Operation?

Sawmilling and side milling differ in their fundamental methods and applications. In sawmilling, raw logs are cut into planks or boards using large rotary saws or band saws. Side milling, on the other hand, is a machining process that removes material from the side of a workpiece, typically metal or plastic, using rotating cutters. While side milling is excellent at producing smooth surfaces and complex side profiles, sawmilling is more suited to turning logs into a variety of lumber products. The two processes are applied in a variety of manufacturing and woodworking scenarios according to these operational differences.

How Is Sawmilling Different From Form Milling in Terms of Materials Used?

There are major differences between sawmilling and form milling in terms of materials used and process goals. Sawmilling is mostly the longitudinal cutting of wood with band saws or rotary blades used to turn logs into lumber. Conversely, form milling, a CNC milling process, focuses on creating asymmetrical shapes with curves or a mix of curves and straight lines. Form milling cutters enable the fabrication of complex shapes in materials like metal or plastic, but rarely wood. Form milling, which offers accuracy and efficiency in industrial operations, demonstrates adaptability in shaping materials with uneven curves, whereas sawmilling shines in wood processing.

What Equipment is Used in Sawmills?

Basic sawmill equipment includes headrigs (band or circular saws), log carriages, conveyor systems, hydraulic log turners, and control systems, often automated or CNC-based. The band saw is essential for creating accurate cuts in logs, while the conveyor makes raw material transportation easier. During the milling process, hydraulic components allow for effective and controlled adjustments. Even with automation, manual control remains important to ensure operational oversight and accuracy. Interestingly, mobile sawmills, which are built to be flexible, often sit atop trailers for easy transfer to lumber sites, demonstrating how these essential elements are combined into a small, transportable design.

What Types of Materials Can Be Processed in Sawmills?

A variety of tree species are processed in sawmills:

- Softwoods: Derived from coniferous trees, they are commonly used in outdoor building materials and furniture due to their durability. Examples are fir, pine, redwood, and cedar.

- Hardwoods: Angiosperm trees are the specialty of hardwood mills, which produce lumber with a range of qualities appropriate for a variety of uses. This range of hardwoods highlights sawmills' versatility in meeting the specific requirements of several industries. Examples are birch, maple, oak, and ash.

What Products Are Typically Produced in Sawmills?

The products that are typically produced in sawmills are listed below:

- Boards: Characterized by a flat surface and diverse dimensions, boards represent a crucial output. These versatile components find application in a myriad of projects, from crafting furniture to constructing intricate woodworking designs.

- Timbers: These large-cut sections and posts play a pivotal role in construction, providing structural support and stability. Timbers sourced from sawmills contribute to the robust framework of buildings and infrastructure.

- Dimensional Lumber: As the most prevalent output, dimensional lumber adheres to standardized dimensions, ensuring versatility in applications across construction and woodworking. It serves as a foundational material for numerous structural and woodworking projects.

How Does Sawmilling Affect the Environment?

Studies indicate that sawmilling can have significant environmental impacts if waste materials are not properly managed. Pollution from sawmill waste, including both physical debris and chemical contaminants, can result from improper storage and disposal practices. The chemical preservation of wood intended for outdoor use can release potentially hazardous substances into the environment. Once released, these substances can pose risks to human health and aquatic life. Research has also indicated that runoff from sawmill waste can threaten surface water quality. Identifying and addressing these environmental issues are essential for ethical and sustainable sawmilling practices.

Do Sawmills Only Work With Wood Materials?

No, sawmills are primarily designed for woodworking, but some users have adapted them for cutting non-wood materials such as insulation foam and upholstery foam. In these cases, sawmill machinery has been used to cut thermal insulation materials for residential buildings. Additionally, some have employed sawmills to cut upholstery foam for applications such as car seats and filters. These adaptations demonstrate the potential for processing a broader range of materials with sawmills, though wood remains the primary material.

What Are the Key Safety Measures in Sawmill Operations?

There are several key safety measures in sawmill operations. First, visible warning signs are essential for alerting employees to possible risks. It will often be prudent to set off alarms upon even the slightest threat from machinery or fire. To reduce the risk of laceration, blade guards, which serve as barriers between personnel and sharp components, should be regularly inspected and maintained. Regular inspections of lumber piles and adherence to proper stacking practices aid in accident prevention. Hydraulic system repairs must be done on time to prevent mishaps and equipment damage. Expert support is provided for a successful outcome. The well-being of sawmill employees is given priority by these extensive safety precautions, which provide a safe working environment.

How Has Modern Technology Impacted Sawmilling?

Modern technology has significantly transformed sawmilling by introducing automation and enhancing efficiency in this traditionally labor-intensive process. Today's sawmills are equipped with advanced machinery, leveraging lasers, sensors, and scanners to guide logs on tracks, optimize cuts, and ensure accuracy. Innovations like color vision technology and geometric scanning play pivotal roles in determining the wood grade and optimizing cutting strategies. This integration enhances both production efficiency and product innovation, showcasing the industry's adaptation to advancements in the digital age.

What Is the Economic Importance of Sawmills?

Sawmills, such as the Harrop-Procter Community Cooperative in British Columbia, play a crucial role in balancing social, economic, and environmental objectives. A yearly harvest of 10,000 cubic meters of logs supports seven to eight full-time equivalent jobs, demonstrating the economic significance of the area. Over time, the efficiency of the sawmill and its strategic planning enable ecologically sound forest practices that reduce negative impacts on watersheds. Furthermore, the sawmill contributes to social well-being and environmental sustainability by creating high-end goods locally and donating lumber for community initiatives, demonstrating its diverse economic value.

Are Sawmills Used in Woodworking Industries?

Yes. Sawmills are integral to the woodworking industry, as they convert raw logs into rough-squared sections, boards, and planks. This primary processing step supplies essential materials for diverse woodworking applications. The lumber produced by sawmills serves as the foundational resource for crafting furniture, construction materials, and countless wood-based products.

What Is the Difference Between Sawmilling and Thread Milling?

Sawmilling and thread milling are two distinct machining processes. For purposes like producing timber, sawmilling is the process of cutting material using a saw blade, usually in straight lines. On the other hand, thread milling is a process that uses a specialized tool to create threads in a workpiece. Although cutting is a part of both processes, there are notable differences in their goals and equipment. While sawmilling is more concerned with cutting and shaping materials, thread milling is more concerned with producing threaded surfaces in a variety of materials.

For readers interested in machining processes beyond woodworking, check out our guide on How Thread Milling Works.

Summary

This article presented sawmilling, explained it, and discussed the materials used and its various applications. To learn more about sawmilling, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including machining and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.