Taper is a word used to refer to a geometrical shape that describes geometry with a gradual reduction in cross-sectional area. Machining tools commonly have a tapered end designed to aid the changing of tools.

This article provides detailed information on the eight types of tapered tools used by different machining equipment as well as the different methods of producing a geometrical taper.

What Is a Taper?

A taper is a uniform reduction in the cross-section or diameter of a part. When a taper is applied, the resulting part will often resemble the shape of a cone. In the cone example, the cross-section is tapered to a point. However, in the case of a taper tool, the part is just tapered from a wider cross-section to a narrower cross-section.

What Is the Purpose of a Taper in Machining?

In machining, the primary purpose of a taper is to enable precise alignment and quick, secure attachment of tools to the spindle. Tapers simplify tool changes, reduce setup time, and eliminate the need for complex clamping mechanisms. They also ensure concentricity between the tool and the machine axis, which is crucial for machining accuracy.

How Does Taper Work?

Tapers work by matching conical surfaces on the tool and spindle, which generate frictional holding power when fitted together. The snug fit allows for a secure connection without external fasteners in many cases. In heavier-duty operations, additional features like a drawbar or alignment keys are used to prevent slippage and ensure rotational stability.

What Are the Different Types of Taper?

There are eight different types of tapered tools in use, which all work on the same principle. The tapered tools each vary based on the size they are available in and whether they are quick-release or self-holding. Each of these tapers is discussed below:

1. Jarno

The Jarno taper standard was introduced by Brown and Sharpe Manufacturing. All Jarno tapers have a consistent taper of 0.600 inches per foot. Jarno tapered tools are used as headstock and tailstock spindles on lathes and for profiling and die-sinking machines. The Jarno taper series includes 19 sizes, with large-end diameters ranging from 0.25 to 2.50 inches and small-end diameters from 0.20 to 2.00 inches.

2. Jacobs

A Jacobs tapered tool has a self-holding taper—meaning no drawbar is required. The Jacobs taper ratio will vary depending on the size of the taper. The Jacobs taper is used for light-duty applications since it is self-holding. Jacobs tapered tools are almost exclusively used to secure a drill chuck to an arbor. Jacobs taper comes in 9 sizes, and each size is referred to as JT + a number. For example: JT0, JT2 short, JT2, and JT6.

3. Brown and Sharpe

Brown and Sharpe tapered tools have a standard taper ratio of 0.50 inches per foot. They are most commonly found on older machine tools and were widely used for drill bits, reamers, end mill holders, and collets. There are 18 standard Brown & Sharpe tapers, with large-end diameters ranging from 0.24 to 3.42 inches and small-end diameters from 0.20 to 3.00 inches.

4. Morse

A Morse tapered tool is a tapered spindle used for tool mounting. Morse tapers are used in a variety of applications, including reamers, drill bits, mill holders, collets, and lathe centers. Morse taper is available in eight sizes from MT0 to MT7 and comes as a self-holding taper. All of the different Morse sizes have a taper of approximately 0.625 inches per foot. The Morse taper end is self-holding and needs to be modified if use with a drawbar is required.

5. BT Tapers

BT tapers are standardized spindle tapers widely used in high-precision CNC machining centers. BT tapers come in various sizes, such as BT30, BT40, and BT50, and are typically used in applications requiring high rigidity and repeatability.

6. HSK Taper

HSK tapers are hollow and short and have a taper ratio of 1 in 10, or 1.20 inches per foot. The short length of HSK tapered tools keeps the spindle of the machine close to the workpiece. There are various uses for HSK tapered tools depending on which variant is used, including lathes, milling machining, and grinding machining. There are 36 HSK sizes, which are divided into six categories HSK-A to HSK-F.

7. NMTB Taper Family

NMTB stands for the National Machine Tool Builders’ Association, set up in 1927. These tapers have a taper ratio of 3.50 inches per foot and have seven common sizes: NMTB-25, 30, 35, 40, 45, 50, and 60. The NMTB taper was designed specifically for use in NMTB spindles, which use a drawbar to secure the shank in the spindle. There is a single flange on NMTB tapers with two keyways for heavy-duty applications.

8. R8 Taper

The R8 taper is also referred to as the M1TR taper. R8 tapered tools, which are secured in their spindles with a drawbar, were designed by Bridgeport Machines, Inc. specifically for use on milling machines. The end of this taper is a direct collet and is held in place by a drawbar. R8 tapered tools are available in 26 sizes starting at 1/16 inch and going up to ⅞ inch in 1/32 inch increments.

Where Is Taper Used?

A taper tool serves as a standardized interface between the machine spindle and cutting tools in equipment such as lathes, milling machines, and drilling machines. It allows for fast and secure installation of tools while enabling a wide range of tool sizes. By using a tapered interface, machines can maintain high accuracy and repeatability during tool changes without the need for time-consuming chuck adjustments.

Accounting for taper standards during the design phase is critical to ensure proper tool fit, alignment, and repeatability in CNC machining. A well-chosen taper can significantly improve manufacturing efficiency and accuracy.

What Is Taper Turning?

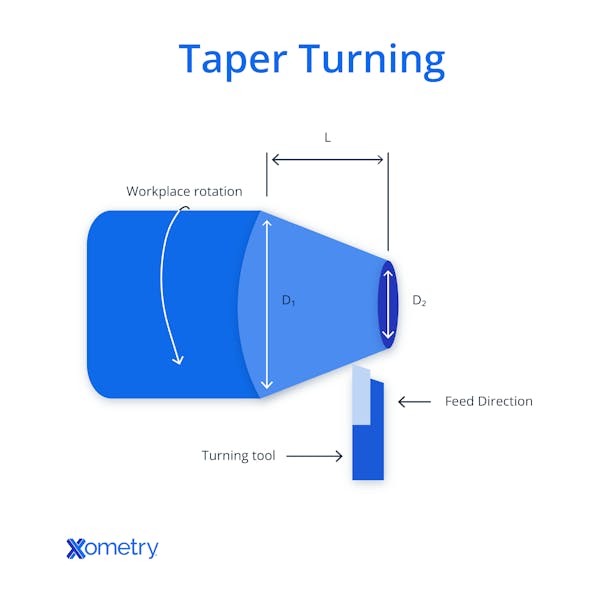

Taper turning is a lathe operation used to create a conical shape by gradually reducing the diameter of a cylindrical workpiece along its length. The method is valued for its ability to generate precision tapers while controlling heat buildup and tool wear. The outcome is a clean taper with a smooth surface finish suitable for tool holders and mating parts.

What Are Taper Turning Methods?

Taper turning can be achieved using several setups, depending on the desired precision and taper length. Common methods include:

- Tailstock Set Over, for short, gentle tapers.

- Taper Turning Attachment, which guides the tool along an angled path.

- Form Tool, which shapes the profile directly in one pass.

- Combining Feeds, in which longitudinal and cross feeds move together diagonally.

What Is the Taper Ratio Formula?

The taper ratio is calculated using the formula:

K=(D - d)/L

Where:

K = The taper ratio

D = The large diameter

d = Smaller diameter

L = Length of taper

For example, if the larger diameter is 5 inches, the smaller diameter is 2.5 inches, and the length is 3 inches, then the values can be plugged into the formula as shown:

K=(5-2.5)/3

K =0.83

This formula can be used for any unit of measure as long as the units are the same for all values.

How To Calculate the Taper Ratio?

To calculate the taper ratio, measure the large and small end diameters of the taper, as well as the length between the two ends. The measurements can be taken in metric or imperial units as long as all of the measurements use the same units. Plug the numbers into the taper ratio formula. The value provided by the formula will be the taper ratio, which denotes the reduction in a cross-section per unit of length.

What Are Example Applications of Taper?

Tapered tools are used in various machining processes to simplify tool mounting and dismounting:

- Milling machines use tapers to secure rotary cutting tools for contouring and shaping materials.

- Lathes employ tapered fittings to align and stabilize tools or workpieces during high-speed rotation.

- Pillar drills benefit from tapered arbors for quickly swapping drill bits and accommodating diverse bit sizes.

Is Taper Only for Cylindrical Objects?

No. Tapers are most common in cylindrical parts, but they can also be applied to non-cylindrical geometries like square or rectangular bars. These are typically created using milling rather than turning processes, allowing angled surfaces to reduce cross-section progressively.

Is Tapering Only for Design Purposes?

No. While tapering can serve aesthetic or ornamental goals—such as in architectural elements—its primary function in machining is mechanical. Tapers help with precise alignment, secure tool holding, and efficient force transmission in high-speed and high-load applications.

Is a Lathe Machine Used for Tapering Materials?

Yes, a lathe is one of the most efficient tools for creating accurate tapers on cylindrical workpieces. It supports multiple taper-turning techniques that vary in complexity and application. Lathes are favored for their precision and versatility when producing tapers of different lengths, angles, and surface finishes.

Summary

This article presented taper, explained it, and discussed its purpose and types. To learn more about taper, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including CNC machining and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.