Xometry is familiar with all sorts of threads and threading techniques, allowing us to make custom parts with everything from standard UN or metric threads to custom thread forms. Tapping and threading both involve the creation of threads, but there are some differences.

Let’s take a look at the similarities and differences between these two terms, starting with the area where most confusion stems from: tapped and threaded holes.

Tapped Holes Definition and Comparison to Threaded Holes

Threaded holes are holes with internal threads created using threading tools such as taps, thread mills, or with the aid of threaded inserts. In engineering, fastened parts aren’t complete without threaded holes. Threads are often added during CNC machining for speed and accuracy. It is common for threading to be one of the final steps of making a part, especially if threaded inserts are involved.

What are the Advantages of Tapped Holes Compared to Threaded Holes?

An advantage of tapping compared to threading is speed. High-speed tapping centers with a rigid tap can thread holes in far less time than it would take to thread mill the same spots. Additionally, tapping can thread deeper holes in more rigid materials such as steel.

What are the Disadvantages of Tapped Holes Compared to Threaded Holes?

One disadvantage of a tapped hole compared to threading is that a different size tap is needed for each size hole being threaded, consuming many valuable but limited positions in the tool magazine. Plus, having to switch tapping tools for each different-sized holes increases the cycle time.

The other disadvantage is that tapping doesn’t let the thread fit be adjusted. Once the hole is tapped, the thread’s size and position are final. Also, rigid taps are used only for the internal thread of holes.

Threaded Holes Definition and Comparison to Tapped Holes

A tapped hole is simply a type of threaded hole. More specifically, it is a threaded hole produced by using a tap. These tools consist of a rod with sharp edges or teeth that cut into the sides of holes, forming internal spiral grooves (threads) as they cut away material. Tapping is a fast and convenient way of threading a hole and is one of the most common techniques we see in our shops.

What are the Advantages of a Threaded Hole Compared to a Tapped Hole?

One main advantage of a threaded hole compared to tapp is controlling the fit. A threaded hole is milled at a high RPM. The drill tool helixes into an already made hole. So, the machine operator can adjust thread size using a strategy similar to an end mill rather than a drill bit.

Another advantage is that a single tool can be used in thread milling to make a wide range of hole sizes. This reduces tooling costs and time. In addition, a thread mill can create interior and exterior threads, right-hand and left-hand threads, and huge threaded holes. With large holes, using a single tool means engineers don’t have to invest in a large rigid tap.

What are the Disadvantages of Threaded Holes Compared to Tapped Holes?

One disadvantage of a threaded hole compared to a tapped hole is that it requires a high-speed spindle. Threading also takes a long time, as the machine controller also spends much time ensuring precision.

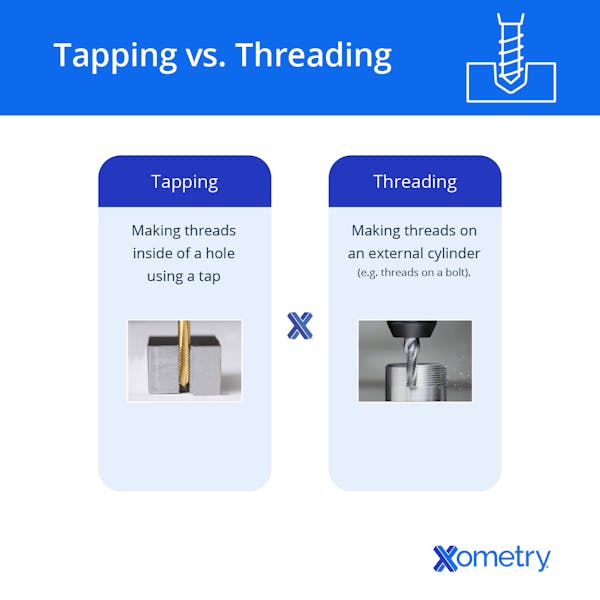

Tapping vs. Threading

As mentioned above, tapping is a type of threading process for creating internal threads in holes. Threading is a generic term used to describe when threads, either internal or external, are created using various types of cutting tools. You can thread a hole or bore to create internal threads, but you can also thread external cylindrical features to create threaded rods or fasteners. External threading can be accomplished using a cutting die, a single-point cutting tool on a lathe, roll forming tools, and more.

FREE CNC Machining Design Guide

Tapped Holes vs. Threaded Holes: Lead Cost Comparison

Threaded holes have a smaller lead cost. Because a single tool can be used in thread milling to make a wide range of hole sizes, this reduces tooling costs and time.

Tapped Holes vs. Threaded Holes: Speed Comparison

Tapping is faster than threading when it comes to a speed comparison. High-speed tapping centers with a rigid tap can thread holes in far less time than it would take to thread mill the same spots. A tapped hole is faster to machine.

Tapped Holes vs. Threaded Holes: Volume Comparison

Threading works better for high-volume production where different size holes or threads are required, as a single tool can be used for different sizes, so time doesn’t have to be wasted changing tools. In addition, various taps are available to match almost any screw-type, including metric and standard measurements.

Tapped Holes vs. Threaded Holes: Materials Comparison

A tapped hole works better with harder materials than threading, and is better for steel. However, both processes are used for hard materials where fasteners cannot cut their own thread.

What Are the Mutual Alternatives to Tapped Holes and Threaded Holes?

A screw clearance hole can be used as an alternative to a tapped or threaded hole, when a screw or bolt is needed. A tapped hole is also similar to a pilot hole, the difference being the threads.

What Are the Similarities and Limitations Between a Tapped Holes and Threaded Holes?

The tapping and threading processes are similar in that they both create internal threads for a threaded fastener, such as a bolt, to fit into. They can also both be used with blind or through holes. A hole is considered blind when it does not go entirely through the workpiece.

As far as limitations go, we will focus on the limitations of tapping since threading encompasses all other types of thread-creation techniques. Here are limitations to be aware of with tapping:

- Thread Type: Tapping is limited to internal threads only. For external threads you will have to turn to other threading processes, such as using dies.

- Thread Variety: A tap is designed to create a thread with a specific size and pitch. This means if you want to create a variety of threads, you will need a corresponding tap for each. Additionally, this rules out custom thread forms, which would be better handled with a process like thread milling.

- Tool Breakage: Taps are more susceptible to breaking than other threading tools. Broken taps can become nightmares for a machinist as they can be difficult to remove, even warranting scrapping the entire part in some instances.

- Blind Hole Depth: Since most taps have a tapered lead on them to assist with the cutting process, this means they can only go so deep before hitting the bottom of a blind hole. If you need your threads to get as close to the bottom of a blind hole as possible, you may need to resort to other methods, such as thread milling.

- Material Limitations: Taps do not work the greatest on hard or brittle materials, such as hardened steel. These type of materials tend to quickly wear down taps, making them ineffective at producing good threads, or requiring frequent tool replacements, which increases cost. On the flip side, very ductile materials can also cause issues for taps, as they can become "gummy" and stick to the tap during the cutting process, requiring frequent tool cleaning or swaps.

Overall, tapping can be a great way of threading holes in parts under the right circumstances, but you may need to resort to other techniques when working with certain materials and thread forms or when you want to mitigate tool breakage risk.

How Xometry Can Help

In short, a tapped hole is a type of threaded hole, but a threaded hole is not always a tapped hole. With Xometrys Instant Quoting Engine® we make it easy to call out the number of threads a part has to ensure an accurate quote and to easily communicate part requirements to the manufacturing shop.

At Xometry, we deal with all sorts of internal and external threads on a daily basis. We can create everything from standardized UN and metric threads to fine-pitch optical threads to completely custom forms. We are also experienced with using various types of inserts such as press-fit, helical, key locking inserts, and more to add threads to parts.

If you have custom parts that require threads, consider Xometry for your next project. You can get instant pricing and lead times by uploading your CAD files to the Xometry Instant Quoting Engine® and configuring your automatic quote today!

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.