Anodizing is the deliberate oxidation of the surface of metals by electrochemical means, during which the component oxidized is the anode in the circuit. Anodizing is most commonly applied to aluminum, and processes also exist for titanium, magnesium, zinc, niobium, zirconium, hafnium, and others. These metals form tough and well-integrated oxide films that exclude or slow further corrosion by acting as an ion barrier membrane.

Titanium anodizing is the controlled oxidation of titanium to alter its surface properties, improving wear resistance and cosmetic appearance. This article will discuss titanium anodizing, its purpose, uses, operation, benefits, limitations, and key properties.

What Is Titanium Anodizing?

Titanium anodizing is the deliberate electrolytic oxidation of the surface of titanium (or titanium alloy) components to produce surface properties suited to the application for which the part is being made. The electrolytic chemistries differ between aluminum and titanium anodizing and also among titanium anodizing types I, II, and III.

What Is the Purpose of Titanium Anodizing?

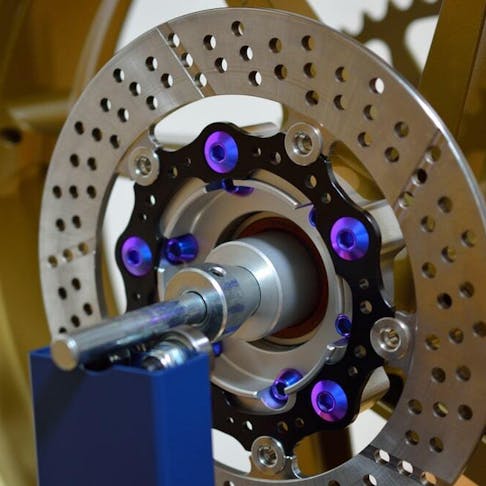

Titanium anodizing can provide a variety of useful properties that enhance the characteristics of components for a wide spectrum of applications. Type II anodizing produces a dense, matte-gray oxide layer that increases wear and corrosion resistance. It is used in aerospace and medical components for improved lubricity and durability. Type IV anodizing, an extension of Type II with PTFE (Teflon™) impregnation, provides a self-lubricating and anti-galling surface. Type III anodizing forms interference-color oxide films that serve mainly cosmetic or identification purposes. This property is generally cosmetic and produces resilient “false” color films that exploit the “oil-on-water” color effect. This cosmetic treatment can have great technical value in differentiating parts to ease assembly. It is also used on surgical implants to differentiate left- and right-hand versions, helping surgeons select the correct components.

Where Is Anodized Titanium Used?

Titanium is most effective where toughness, fatigue resistance, and low weight are essential, particularly in applications requiring enhanced corrosion resistance or high-temperature performance. Titanium anodizing enhances corrosion resistance and produces color without dyes, but the surface is not completely chemically inert under all conditions. Titanium is widely used in jet engines, rocket engines, and airframe components. Titanium anodizing is applied on aerospace hardware for wear reduction, lubricity, galvanic corrosion control, and part identification rather than as a general exterior “skin” finish.

Titanium has a very low susceptibility to chloride ion (salt) induced corrosion and lends this characteristic to a range of alloys. These are increasingly being used in high-value and high-performance boat, ship, and fishing components to provide high strength, low weight, and (particularly) low corrosion performance compared to even the most effective “marine” stainless steels. These applications include oilfield and subsea components, dive equipment, fishing gear, pumps, and valve parts. Anodized titanium is a material of choice for the widest range of surgical and dental implant parts, combining high strength with low weight and very low biologically induced corrosion.

How Does Titanium Anodizing Work?

Titanium anodizing works by forming an enhanced oxide film on the part’s surface through electrochemical processes that vary depending on whether the part undergoes Type I, II, or III anodization. This coating can be a “thin film” that lends false color to the part; Type III typically creates this effect. Interference colors in titanium anodizing arise from oxide thickness, commonly on the order of ~200-1000 Å (20-100 nm) for many practical color ranges, with exact thickness tied to applied voltage and process chemistry. Type II anodizing produces tougher, thicker coatings that improve wear resistance. Type IV anodizing creates a self-lubricating film that impregnates the oxide layer with PTFE. Type I anodizing is used for specialized high-temperature forming and for functional properties such as thermal-control surfaces. Titanium quickly forms a native oxide layer of roughly 10-20 Å (1-2 nm) within hours, which in ambient air typically stabilizes around 200-250 Å (20-25 nm) without anodizing.

What Are the Benefits of Titanium Anodizing?

There are several benefits of titanium anodizing, including:

- Reduced risk of galling through lower friction and improved lubricity of the oxide surface.

- Improved corrosion resistance due to the stable and adherent oxide layer formed during anodizing.

- High biocompatibility from chemically inert, low-ion-release surfaces suitable for surgical implants.

- Durable interference colors obtained without pigments or dyes, generally at low processing cost for small components.

- High cosmetic quality and a wide spectrum of colors.

- An electrically insulating and corrosion-resistant surface.

- Biocompatible part identification through interference colors that require no dyes or colorants.

Titanium anodizing turns a functional material into a surface that is both durable and distinctive, combining engineering performance with visual precision.Audrius ZidonisPrincipal Engineer at Zidonis Engineering

What Are the Limitations of Titanium Anodizing?

The limitations of titanium anodizing are:

- Precise color control can be difficult because small variations in voltage, electrolyte composition, or surface finish change the oxide thickness and therefore the perceived color.

- Common electrolytes for titanium anodizing include phosphoric, sulfuric, and occasionally organic acids; older chromic-acid baths are largely discontinued due to toxicity and environmental regulation.

- Scratched or damaged anodized layers do not self-heal quickly; regrowth occurs only under oxidizing conditions. In oxygen-poor or reducing environments, the oxide may not reform effectively. Although such environments are not corrosive, other issues, such as chemical-induced stress corrosion cracking, can arise.

- Titanium anodizing does not ensure corrosion resistance in all environments. Certain titanium alloys can suffer stress-corrosion cracking or embrittlement in environments such as anhydrous methanol, nitrogen tetroxide, red-fuming nitric acid, or halogen gases.

Common FAQs About Titanium Anodizing

How To Anodize Titanium

To anodize small titanium parts, you can create a simple electrolytic cell using a DC power supply and a suitable electrolyte, connecting the titanium workpiece as the anode and the counter-electrode (often stainless steel or aluminum foil) as the cathode. The applied voltage determines oxide thickness and resulting color. Color depends primarily on applied voltage, with electrolyte chemistry and surface condition having secondary effects. Precise control is hard to achieve and maintain, but satisfying results can be shown very easily.

What Are the Materials Needed To Anodize Titanium?

The materials needed to anodize titanium are:

- Electrolyte: The electrolyte can be a moderately concentrated sulfuric acid (1 to 2 M is appropriate) or a concentrated borax (sodium tetraborate) solution. Many other ionic solutions will work.

- Plastic Tank: The plastic tank should be of a suitable size for immersing the part. If aluminum foil is used as the cathode, it must be electrically connected to the negative terminal; otherwise, the bath is not itself lined as an electrode. The tank is filled with the electrolyte and serves as the cell, connecting all circuit components.

- DC Power Supply: A DC power supply should be capable of supplying 0 to 30 volts and several amps of current. This will drive the anodization process.

- Wires: The wires will be used to connect the aluminum foil to the negative of the power supply (the cathode) and the titanium part to the positive of the power supply (the anode).

How Long Will Anodized Titanium Last?

The anodized surface of titanium is stable for many years if undamaged. Titanium shows excellent corrosion resistance and a high position in the galvanic series, so galvanic attack is minimal but not entirely absent when coupled with carbon or noble metals.

How Long Does It Take To Anodize Titanium?

Color anodizing typically produces visible results within seconds when voltage is applied; electrolyte concentration has only a minor influence. Forming thicker, functional (Type II) coatings requires longer dwell times, typically several minutes to tens of minutes, rather than hours. This process is substituting for the natural development of titanium oxide films, which occurs in wet environments over 3 to 5 years.

Is Anodized Titanium Prone to Rust?

No, anodized titanium is not prone to rust. Very little can affect anodized titanium when a well-integrated and tough oxide film has formed. Titanium does not corrode rapidly, other than under exceptional and very aggressive conditions.

Is the Anodizing of Titanium Permanent?

No, titanium anodizing is not permanent. Anodized titanium oxide films can be removed by abrasion, so hard-working parts can lose some of their anodized coatings. Removing anodized films from titanium typically requires chemical etching in mixtures of nitric and hydrofluoric acids under controlled conditions, sometimes heated, following ASTM F86 or AMS 2488 cleaning guidelines. This is not a common condition, however. Otherwise, titanium anodizing is very robust. Components anodized decades ago have been found to remain in near-original condition.

How Xometry Can Help

Xometry provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free titanium CNC machining quote.

Copyright and Trademark Notice

- *Teflon™ is a trademark of The Chemours Company FC, LLC

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.