As far as the most common everyday materials go, stainless steel would rank pretty highly on the list. From the water bottle you carry to work to the pipes lining the house or building you live in, this material’s superb features make it abundant in our day to day lives. It also spans a wide array of sectors and is popular in air fields and engineering hubs as well as medical settings and can be used in all kinds of manufacturing scenarios, like 3D printing and sheet metal cutting.

There are many types of stainless steel grades out there and we’re putting the spotlight on 18/10—a steel that won’t let you down when it comes to rusting and maintaining its sleek appearance.

What is 18/10 Stainless Steel?

The numbers in its name come from its chemical composition, which usually consists of roughly 18% chromium and 10% nickel. There are, of course, other elements in the mix, including a hefty portion of iron (anywhere between 66% and 71%) and smaller amounts of things like manganese, silicon, and carbon.

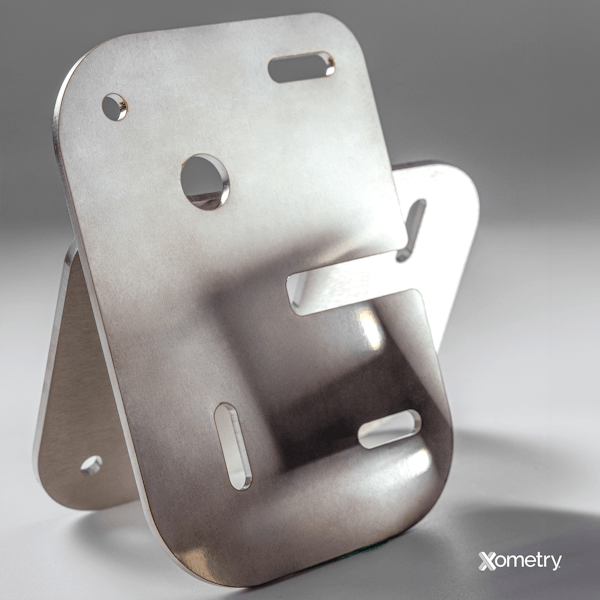

It’s often compared to 18/0 and 18/8 stainless steels, and out of all three, 18/10 is normally viewed as the highest quality because of its level of corrosion resistance, although it does come at a higher price. In the image below, you can see an example of stainless steel machined parts that we’ve made here at Xometry.

Creating this specific type of stainless steel isn’t too dissimilar from any other type and involves mixing large quantities of scrap steel in an electric arc furnace until it melts down into a molten substance. Then the steel gets processed to remove impurities and create its low carbon content. Following this, it’ll get cast and molded into different shapes, then cooled and readied for processing and shipping out to other manufacturers where it can take its final form.

There are so many different products that use 18/10 stainless steel—here are just a few:

- Pots and pans

- Eating utensils

- Bottles, bowls, and food storage containers

- Tubes

- Nuts, bolts, and washers

- Brewery equipment like fermentors

Characteristics and Composition

To give you a good idea of how 18/10 stainless steel functions, what it consists of, and how it reacts to certain environments, pressures, and conditions, we’ve outlined its chemical and physical characteristics. Knowing these factors will help you choose between the different types of stainless steels out there and help you better understand how they compare to one another.

As a quick refresher, 18/10 is one type of steel that’s easy to mold and it has one of the best corrosion resistance levels compared to 18/8 and 18/0. It also has great heat resistance and, because it’s nonporous, it’s a piece of cake to clean and ideal for environments that require sterile conditions—like hospitals, doctors’ offices, and restaurants. Lastly, it’s a nonmagnetic steel and can only have this property if it’s blended with other metals and alloys like aluminum.

Chemical Composition

These are the specific percentages of alloying elements that make up 18/10 stainless steel:

| Element | Percentage composition |

|---|---|

Element Iron | Percentage composition 66.7– 71.27 |

Element Chromium | Percentage composition 17.5–19.5 |

Element Nickel | Percentage composition 8–10.5 |

Element Manganese | Percentage composition 2 |

Element Silicon | Percentage composition 1 |

Element Nitrogen | Percentage composition 0.1 |

Element Carbon | Percentage composition 0.07 |

Element Phosphorus | Percentage composition 0.045 |

Element Sulfur | Percentage composition 0.015 |

| Property | Value |

|---|---|

Property Density | Value 7.9 g/cm^3 |

Property Yield strength | Value 200 MPa |

Property Hardness (Rockwell B) | Value 75 |

Property Magnetism | Value Non-magnetic |

| Thermal Property | Value |

|---|---|

Thermal Property Melting point | Value 1,400–1,455 °C |

Thermal Property Rate of thermal expansion at 20 °C | Value 16.5 x 10^-6 mm/m/°C |

Thermal Property Thermal conductivity | Value 15 W/m.K |

Common Formats

After stainless steel is gooey and molten, it has a few different options when it comes to taking its hardened form.

Sheet or Plate

These are flat sections of stainless steel that you can bend, shape, laser, and cut into different objects like worktops, panels, or kitchen countertops.

Bar

These can take a few different shapes, like squares, rounds, rectangles, or hexagons, and they’re a great option for turning into fasteners and hardware like bolts and screws.

Forged

This type of stainless steel normally gets turned into pipes or bars, but it’s processed in such a way that makes it even stronger and more durable.

You can see a picture of another style of stainless steel part made at Xometry below.

| Country | Name |

|---|---|

Country EU | Name X5CrNi18-10 |

Country USA | Name 304 |

Country Germany | Name X5CrNi18-9 |

Country Japan | Name SUS304 |

Country France | Name X5CrNi18-10 |

Country England | Name X5CrNi18-10 |

Country Italy | Name X5CrNi18-10 |

Country Russia | Name 08KH18N10 |

Country China | Name 0Cr18Ni9 |

Advantages and Disadvantages

Working with 18/10 stainless steel has its benefits, especially compared to other types of steel or metal:

- It has top-notch corrosion resistance in comparison to other stainless steels

- The surface finish is much shinier and nicer to look at when up against other metals

- It’s not difficult to maintain and keep in good shape

- It provides decent heat resistance

- It also has a good level of resistance against pitting

Equally, there are a few downsides you’ll want to know about if you opt for this specific grade of steel:

- When you compare this style to 18/0 and 18/8, you’ll find it’s the most expensive

- It’s prone to scratching

- It’s not magnetic, which can be a limitation in some scenarios

- You need special tools to machine and process it

- It’s not great in saltwater environments and will corrode much faster

How Xometry Can Help

At Xometry, we offer our clients a list of services specific to stainless steels and other metals, including sheet metal fabrication, laser tube cutting, metal stamping, and metal extrusion. We also have a wide range of other manufacturing capabilities you can get a free quote for, like 3D printing, plastic injection molding, and powder coating.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.