You have most likely encountered the 18/8, 18/10, and 18/0 grades of stainless steel more than you realize. These steels are used in everything from the pipes that may have brought you the water for your morning coffee to the teaspoon you use to stir it with. Needless to say, these are very valuable materials in the world of manufacturing and are some of the most popular among Xometry customers.

For a quick overview of the differences between these three grades, we’ve outlined what each stainless steel grade consists of chemically, what it’s great (and not-so-good) at, and the ways in which Xometry’s services can be beneficial to processing stainless steel for your own business.

What is 18/8 Stainless Steel?

This kind of stainless steel is a member of the 300 grouping, and its most common and popular grade is 304. Its name basically gives away its composition—it’s got around 18% chromium and 8% nickel. Also included is roughly 67% iron, and a tiny trace of carbon (about 0.07%). It’s also part of the austenitic steel family, meaning they have better corrosion resistance than other families of stainless steel and can’t be hardened through heat treatments. That being said, it falters slightly in corrosion resistance when it comes to sitting in or being constantly exposed to saltwater.

This grade has an extra perk in that it’s food safe, meaning it can be made into cookware, like pots and pans, utensils and cutlery, and even those sleek stainless steel cooking worktops you find in restaurants. To make this grade, all the ingredients, including the alloying elements, have to be mixed together and then melted in an electric furnace. This part of the process takes around 8–12 hours. After that, it has to go through decarburization, which is basically getting rid of any carbon that has been left over, and this is done with argon or oxygen. It’s then poured into molds so that it can harden in the needed shape and size.

What is 18/10 Stainless Steel?

The numbers in 18/10 stainless steel’s name also describe its makeup; it’s got 10% nickel, and around the same amount of chromium as the other two (18%). With that extra bit of nickel, 18/10 steel is known for having slightly better rust and corrosion resistance, making it a great option for flatware, cooking utensils, and kitchen appliances. It can hold its own in high temperatures—earning it another point for use within the food and restaurant industries.

Just like 18/8, the scrap is melted down in a furnace and then decarburized. The only difference is that its ingredients have slightly different proportions, i.e. slightly more nickel. It’s then formed into the shape the manufacturer has in mind and finished in various ways to get the final product.

What is 18/0 Stainless Steel?

This grade has no nickel in it — which is why there’s a zero in its name — but it does have the same amount of chromium as the other two grades. Its lack of nickel or molybdenum means it’s not as resistant to corrosion and oxidation. Perhaps balancing that out is its cost—it’s more affordable than the other two grades.

This steel is made just like the other two (melted in a furnace), just without any nickel. It’s then cast into whatever shape and size is needed, then. Once this is done, manufacturers will anneal it or put it through other processes to boost its benefits and improve its finish.

Comparing All Three Steels

You’ll want to think about the end purpose for the stainless steel you’ll be using and the environment it’ll be in, as well as the budget available for manufacturing and what specific characteristics are necessary. To help you decide, we’ve created the two tables below, which provide the strengths and weaknesses of each type of stainless steel, and their properties.

| Type | Advantages | Disadvantages |

|---|---|---|

Type 18/8 | Advantages

| Disadvantages

|

Type 18/10 | Advantages

| Disadvantages

|

Type 18/0 | Advantages

| Disadvantages

|

Table 1: Comparing All Three Steels

| Property | 18/8 Stainless Steel | 18/10 Stainless Steel | 18/0 Stainless Steel |

|---|---|---|---|

Property Corrosion Resistance | 18/8 Stainless Steel Moderate | 18/10 Stainless Steel High | 18/0 Stainless Steel Low |

Property Nickel Content | 18/8 Stainless Steel 8-10.5% | 18/10 Stainless Steel 10-14% | 18/0 Stainless Steel 0% |

Property Chromium Content | 18/8 Stainless Steel 18-20% | 18/10 Stainless Steel 16-18% | 18/0 Stainless Steel 16-18% |

Property strength | 18/8 Stainless Steel Good | 18/10 Stainless Steel Excellent | 18/0 Stainless Steel Moderate |

Property Cost | 18/8 Stainless Steel Moderate | 18/10 Stainless Steel Higher | 18/0 Stainless Steel Lower |

Property Staining Susceptibility | 18/8 Stainless Steel Moderate | 18/10 Stainless Steel Low | 18/0 Stainless Steel High |

Table 2: Properties of 18/8, 18/10, and 18/0 Stainless Steels

How Can Xometry Help

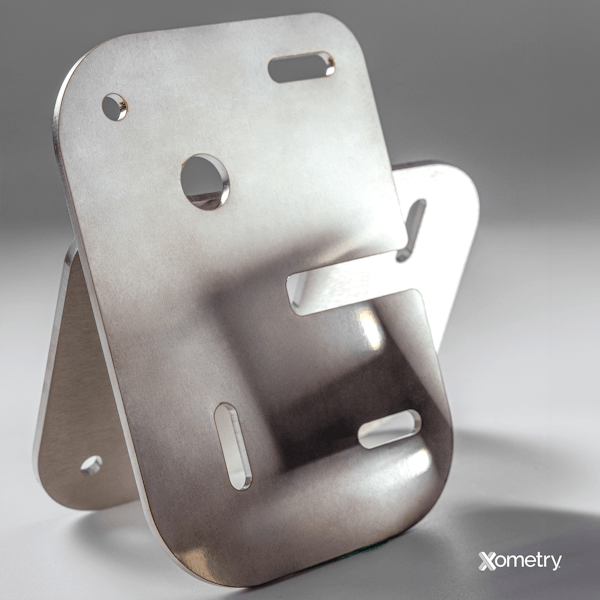

At Xometry, we offer many different grades of stainless steel, including popular choices like grades 304 and 316. Best of all, you can an instant quote for custom-made parts in these materials through the various manufacturing processes we offer, including CNC machining, sheet metal fabrication, sheet cutting, and more!

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.