Martensitic stainless steel (MSS) is known for its hardness, as well as its poor weldability. Like other stainless steels, MSS has good corrosion resistance and strength compared to other metals such as aluminum. Its hardness, weldability, and strength can be modified by either slightly changing the composition of the metal or heat treatment.

This article details martensitic stainless steel’s composition, properties, and applications.

What Is Martensitic Stainless Steel?

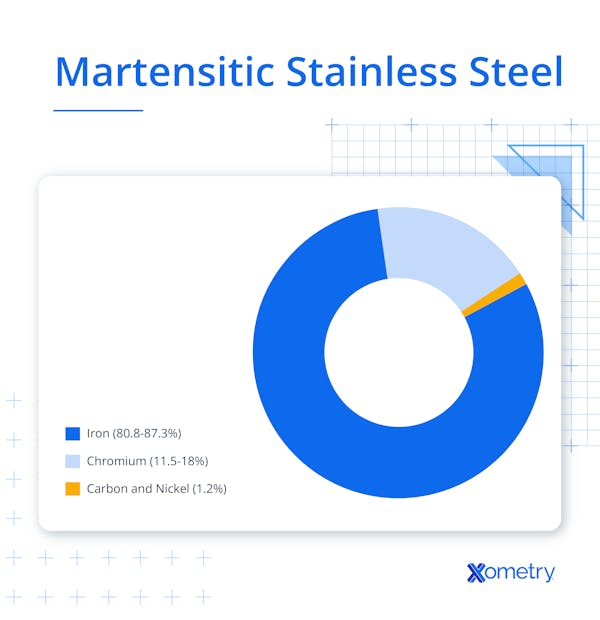

Martensitic stainless steel is one of five different types of stainless steel. It differs from other stainless steels due to its composition. Its composition allows it to harden and strengthen through heating and aging. Like other stainless steels, martensitic stainless steel is made up mostly of iron with the addition of carbon and other alloys. Carbon content in martensitic stainless steels typically ranges from about 0.1% to 1.2%, depending on the grade. The other alloying elements are chromium (11.5-18%) and nickel. The high carbon content makes martensitic stainless steel strong, but the lack of significant nickel reduces its corrosion resistance.

What Is the History of Martensitic Stainless Steel?

The first martensitic stainless steel was invented by Harry Brearley in 1913. This was the first ever “rustless steel.” It took until the 1930s and 1940s to be commercially produced and used.

What Is the Other Term for Martensitic Stainless Steel?

Martensitic stainless steel is referred to as “martensite.” Other names of martensitic stainless steel include martensite steel and the acronym “MSS.”

What Is Martensitic Stainless Steel Made Of?

Martensitic stainless steel is mostly made of iron with the addition of carbon. Carbon levels for martensitic steel can be as high as 1.2%, depending on the grade. Martensitic steel also has 11.5–18% chromium, and a small amount of nickel, manganese, and molybdenum.

How Is Martensitic Stainless Steel Processed?

Martensitic steel is made through the use of quenching and stress relief, or through quenching and tempering. These heat treatments alter the microstructure of the steel to a martensitic structure. This process increases the hardness of the steel.

What Are the Characteristics of Martensitic Stainless Steel?

Key characteristics of martensitic stainless steel include moderate corrosion resistance, high strength, poor weldability, magnetic behavior in both hardened and annealed states, and limited formability.

What Is the Color of Martensitic Stainless Steel?

Martensitic stainless steel is silver/gray in color, similar in appearance to other steels. Additionally, this steel may turn orange/brown when it rusts. The steel may also appear differently when painted.

What Does Martensitic Stainless Steel Look Like?

Martensitic stainless steel usually appears silver or gray, but rust or paint can alter its appearance. If the martensitic steel is not painted, it may be reflective or matte depending on the surface finish of the material.

What Are the Properties of Martensitic Stainless Steel?

Martensitic stainless steel is sometimes called semi-stainless due to its lower alloy content and higher carbon content, which distinguish its hardness, brittleness, and corrosion resistance from other stainless steels. These properties are:

- High hardness: MSS's high carbon content compared to other stainless steels gives it a higher hardness.

- Brittle: Conversely, the high carbon content of MSS also leads to a high brittleness.

- Moderate corrosion resistance: MSS has a lower chromium content than other stainless steels, which reduces its corrosion resistance.

- High tensile strength: The high carbon content of MSS allows it to respond well to hardening and tempering. This can improve the tensile strength of MSS compared to other stainless steels.

In my engineering experience, martensitic stainless steels offer impressive hardness and wear resistance, but they require careful consideration in applications where corrosion resistance or weldability are just as important.Audrius Zidonis, Principal Engineer at Zidonis EngineeringNote from the Editor

| Property | Description | Typical Value Range | Units |

|---|---|---|---|

Property Tensile Strength | Description Tensile strength is the ability of a material to resist plastic deformation when under load. | Typical Value Range 70,000–286,000 | Units psi |

Property Hardness | Description Hardness is the measure of resistance to localized plastic deformation | Typical Value Range ~97 | Units Rockwell B |

Property Density | Description Density is the weight of a material per unit of volume | Typical Value Range 7,800 | Units kg/m^3 |

| Martensitic Stainless Steel Type | Corrosion Resistance | Oxidation resistance | Reactivity | Magnetic properties | Flammability |

|---|---|---|---|---|---|

Martensitic Stainless Steel Type 410 | Corrosion Resistance Lowest resistance | Oxidation resistance Moderate | Reactivity Low | Magnetic properties Ferromagnetic | Flammability Nonflammable |

Martensitic Stainless Steel Type 440 | Corrosion Resistance More resistant than 420 | Oxidation resistance Moderate | Reactivity Low | Magnetic properties Ferromagnetic | Flammability Nonflammable |

Martensitic Stainless Steel Type 420 | Corrosion Resistance More resistant than 410 | Oxidation resistance Moderate | Reactivity Low | Magnetic properties Ferromagnetic | Flammability Nonflammable |

What Are the Different Types of Martensitic Stainless Steel?

Martensitic stainless steel is distinct from other steels due to its composition. However, it can also be further divided into different grades. These grades and their properties are discussed below:

1. 410 Stainless Steel

410 stainless steel in the annealed condition has tensile strength around 40,000–95,000 psi, but when hardened and tempered, it can exceed 110,000 psi. The hardness value can vary depending on the heat treatments applied. 410 stainless steel is used for fasteners, including nuts and bolts, as well as valves, pistons, ball bearings, impellers, turbine blades, springs, pins, and micrometers.

2. 440 Stainless Steel

440 stainless steel has the highest hardness compared to 410 and 420 steel. However, that comes at the cost of reduced formability. This high hardness is sought after for blade manufacturing, as it results in a blade staying sharper for longer. 440 steel is used as blades, in cutlery, surgical instruments, and bearings.

3. 420 Stainless Steel

420 stainless steel is a high-carbon martensitic stainless steel, typically containing 0.3-0.4% carbon. When heat-treated and cold-rolled, 420 stainless steel can be expected to achieve a minimum tensile strength of 120,000 psi. 420 steel has applications in fasteners, machine parts, surgical instruments, and firearms.

4. High-Carbon Martensitic Steel

The percentage of carbon in high-carbon martensitic stainless steel is typically between about 0.6% and 1.2%. The high carbon content of steel makes it stronger by affecting the molecular bonds between the microstructure. The downside of having a high carbon content is that it makes the steel more brittle and reduces its ability to be welded and formed. Due to its high hardness and strength, high-carbon steel is used for knives, ball bearings, molds, and dies.

5. Low-Carbon Martensitic Steel

The carbon composition of low-carbon martensitic stainless steel is 0.05-0.25%. Having a reduced carbon content allows martensitic steel to be more easily formed and welded, but reduces its strength. Low-carbon martensitic stainless steel generally also has better corrosion resistance and weldability. Due to these characteristics, low-carbon martensitic stainless steel is used in gas and oil pipelines, and a trade-off between strength, corrosion resistance, and weldability is required.

What Are the Applications of Martensitic Stainless Steel?

Martensitic stainless steels have different compositions and different heat treatments available. This results in a range of strength, hardness, and corrosion resistance. These varying properties allow martensitic stainless steel to be used in a range of applications, including:

- Surgical instruments

- Turbine blades

- Fasteners

- Bearings

- Bushings

- Valves

- Micrometers

Is Martensitic Stainless Steel Important in Welding?

Martensitic stainless steel is not known for its use in welding. In fact, it is famously hard to weld. This is because martensitic steel tends to harden, especially when heated and air-cooled or quenched. This reaction to heat treatment leads to the worst weldability compared to other stainless steels. Martensitic stainless steel’s high hardness, high thermal expansion, and tendency to form brittle microstructures contribute to weld cold cracking.

What Are the Benefits of Martensitic Stainless Steel?

Martensitic steel’s advantages are listed below:

- Low cost

- Ultra-high strength

- Moderate corrosion resistance

- Air hardens

- Homogeneous weld HAZ/base metal after solution heat treatment

What Are the Limitations of Martensitic Stainless Steel?

Martensitic stainless steel does have its limitations, one of which is that it is difficult to weld. Additional limitations of martensitic steel are:

- Limited corrosion resistance

- Susceptibility to cracking

- Hard to form

- Limited operating temperature due to a lack of oxidation resistance

How Does Martensitic Stainless Steel Differ From Regular Stainless Steel?

Martensitic stainless steel has superior strength and hardness compared to other stainless steels, but its impact resistance is generally lower due to brittleness. It also has lower corrosion resistance, remains magnetic, and has very poor weldability. To learn more, see our guide on Stainless Steel Characteristics.

Frequently Asked Questions About Martensitic Steel

Is Martensitic Stainless Steel Durable?

Yes, martensitic stainless steel is durable. Martensitic stainless steel responds well to heat treatment by hardening. Its hardened state makes martensitic steel durable for use in applications including: valves, turbine blades, and surgical instruments.

Is Martensitic Stainless Steel Magnetic?

Yes, martensitic stainless steel is magnetic. Its body-centered tetragonal martensitic structure is ferromagnetic, unlike austenitic stainless steels, which are generally non-magnetic. To learn more, see our Brittle guide.

Is Martensitic Stainless Steel Rust-Proof?

No, martensitic stainless steel is not rust-proof; however, it is rust-resistant. The term “rust-proof” suggests that the material is immune to rust. While martensitic steel, as with other stainless steels, does have increased corrosion resistance, it is not rust-proof. Additionally, martensitic stainless steel is only moderately corrosion resistant compared to other stainless steels. This is because martensitic stainless steel's primary sought-after property is hardness.

Can Martensitic Stainless Steel Be Hardened?

Yes, martensitic stainless steel can be hardened. While untreated martensitic steel is known for its hardness, it can also be hardened through the use of heat treatment. Martensitic stainless steel is treated by either heating the metal and then air cooling it or quenching it.

Can Martensitic Stainless Steel Be Tempered?

Yes, martensitic stainless steel can be tempered. While martensitic stainless steel is very hard, this hardness comes with increased brittleness. Since this makes martensitic steel too brittle for many applications, it can be tempered to reduce the hardness and brittleness. This is done by heating the martensitic stainless steel to 135-400 ºC for several hours. Tempering reduces brittleness in martensitic stainless steel.

What Is the Difference Between Martensitic Stainless Steel and Austenitic Stainless Steel?

The difference between martensitic stainless steel and austenitic stainless steel includes weldability, corrosion resistance, magnetism, and microstructure. Austenitic steels are non-magnetic, more corrosion resistant, and weldable, while martensitic steels are harder, magnetic, and less corrosion resistant. Austenitic stainless steels are much easier to weld than martensitic grades because martensitic steels typically have a higher carbon content. The high carbon content also reduces corrosion resistance but increases hardness. Although both materials are different, most martensitic stainless steels are made by heating and rapidly cooling austenite. To learn more, see our guide on Austenitic Stainless Steel.

Summary

This article presented martensitic stainless steel, explained it, and discussed its composition and types. To learn more about martensitic stainless steel, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.