PPE-PS is a ductile material with good hydrolytic stability and flame-retardant performance. UV resistance is grade dependent, with some grades carrying a UL 746C F1 outdoor rating and others requiring stabilization. These properties make it ideal for applications in the process engineering, electrical, and medical industries. PPE-PS can be processed using injection molding, extrusion, blow molding, and 3D printing. It is an amorphous polymer and does not have a true melting point. Neat PPE has a glass transition temperature around 210–215 °C, and the Tg of PPE-PS blends decreases as PS content increases.

This article describes what PPE-PS is, its key characteristics, and its potential adverse health effects.

What is PPE-PS?

PPE-PS is a blend of polyphenylene ether and polystyrene. PPE material is an amorphous thermoplastic with a high glass transition temperature of 215°C. Polystyrene is often used in an expanded foam state for product packaging. It is also available in clear and hard forms.

PPE on its own is not often used due to difficulties in processing as it has poor molten flowability. As such, it is often blended with polystyrene to improve processability. PPE can be blended with any proportion of PS. The glass transition temperature tends to decrease with higher proportions of polystyrene. Other additives, such as glass fiber, can also be added to improve mechanical properties.

See the Processing section for methods and parameters.

What is the Filament Specification of PPE-PS?

ThermaX PPE-PS from 3DXtech is a plastic filament typically used in FDM (Fused Deposition Modeling) 3D printers. Parts printed with ThermaX PPE‑PS can exceed ABS in heat resistance and flame rating, but they do not universally outperform polycarbonate across all properties, so comparative performance depends on the metric and print settings. ThermaX PPE-PS prints at high temperatures, and care must be taken when printing with it. ThermaX PPE‑PS is typically printed with a 290–320 °C nozzle, a 90–110 °C bed, and a 50–80 °C heated chamber to limit warping. The filament is available in 1.75 and 2.85 mm diameters. Despite low moisture absorption, PPE‑PS filaments can still absorb moisture and are typically dried at 80 °C for about four hours before printing.

What Are the Characteristics of PPE-PS?

PPE-PS is a ductile, impact‑resistant material with good overall mechanical strength and moisture resistance. The table below summarizes some of the key physical properties of PPE-PS:

| Property | Value |

|---|---|

Property Density [g/cm^3] | Value 1.07 |

Property Glass Transition Temperature [°C] | Value 215 |

Property Melting Point [°C] | Value 200 |

Property Tensile Strength [MPa] | Value 72 |

Property Modulus of Elasticity [GPa] | Value 2.2 |

Property Flexural Strength [MPa] | Value 109 |

Property Flexural Modulus [GPa] | Value 2.54 |

Property Impact Strength [kJ/m^2] | Value 6 |

Table 1: Key Physical Properties of PPE-PS

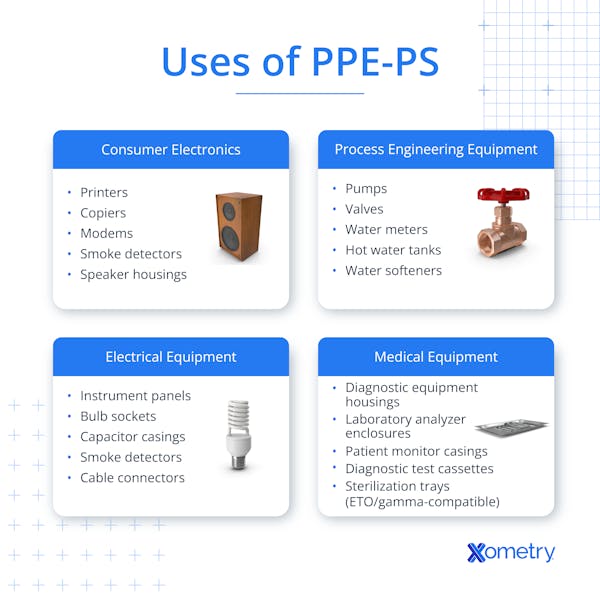

What Are the Uses of PPE-PS?

PPE‑PS is used in the following applications:

- Consumer electronics: PPE-PS is used for housings and covers in devices such as printers, copiers, modems, smoke detectors, and speakers.

- Process engineering equipment: PPE-PS is used for wetted components in pumps, valves, water meters, hot water tanks, and water softeners.

- Electrical equipment: PPE-PS is used for instrument panels, bulb sockets, capacitor casings, and cable connectors.

- Medical equipment: PPE-PS is easily sterilized due to its high temperature resistance and can, therefore, be used for reusable medical devices.

What Are the Advantages of PPE-PS?

PPE-PS is a tough and ductile amorphous material with exceptional impact resistance, low shrinkage, and low creep at elevated temperatures. PPE-PS has good hydrolytic stability, especially at elevated temperatures. It has good chemical resistance to a wide array of acids, bases, and other aqueous chemical solutions. UV and flame performance are grade dependent. Some grades achieve UL 746C F1 outdoor rating and UL94 V-0 flame rating, while others require additives or stabilization. PPE-PS can also produce parts with excellent surface finishes and can be readily painted.

What Are the Disadvantages of PPE-PS?

PPE-PS can experience environmental stress cracking when exposed to some mineral oils and ketones. It can swell or dissolve when exposed to some organic solvents such as aromatic hydrocarbons, and certain aliphatic hydrocarbons, depending on grade and exposure conditions. PPE-PS requires higher than typical processing temperatures. It can provide some challenges to processing, especially in 3D printing, which requires heated enclosures, high extruder temperatures, and high bed temperatures.

Frequently Asked Questions About PPE-PS (Polyphenylene Ether + Polystyrene)

How Does PPE-PS Affect Human Health?

PPE-PS has no major negative effects on human health. Some additives, such as carbon black, are classified as possible carcinogens, but in PPE-PS they are bound in the polymer matrix, which limits exposure risk under normal processing conditions. PPE-PS particles can cause mechanical irritation if they come into contact with the eyes or other sensitive areas.

Is PPE-PS Toxic?

PPE-PS is not shown to be toxic if ingested and repeated skin contact has no adverse effects. Processing fumes can irritate the respiratory tract, and severe exposure to processing fumes can cause nausea and headaches. Over time, a grease-like film can collect on molding equipment and ventilation ducting which can irritate the skin.

Is PPE-PS (Polyphenylene Ether + Polystyrene) a Good Plastic Injection Molding Material?

PPE-PS is widely used for injection molding and produces parts with excellent surface finishes. It also has very low mold shrinkage rates, meaning parts will have excellent dimensional consistency. PPE alone has very poor mold flowability and, as such, it is not ideal for injection molding. With the addition of PS, the PPE-PS blend becomes much easier to process for injection molded components.

For more information on Plastic Injection Molding, see our full Plastic Injection Molding Guide and The Most Common Plastic Injection Molding Materials Guide.

Summary

This article provided a summary of the properties, uses, advantages, limitations, and toxicity of PPE-PS. For assistance with material selection, contact Xometry to connect with our materials experts or request a quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.