Although laser cutting is a widely adopted technology across manufacturing, construction, and design, it is not always the most appropriate or cost-effective solution. Depending on factors such as material type, thickness, heat sensitivity, edge finish requirements, and project budget, several alternative cutting technologies may be better suited.

These non-laser cutting methods are also capable of processing a broad range of materials, including metals, plastics, wood, composites, ceramics, textiles, and even stone, and can achieve high-quality cuts or engravings, offering distinct advantages in specific applications.

This article will explore five alternatives to laser cutting, including waterjet cutting, flame cutting, and plasma cutting. Each of these cutting methods has specific benefits depending on certain factors such as the type of material, thickness, and precision required for the task at hand.

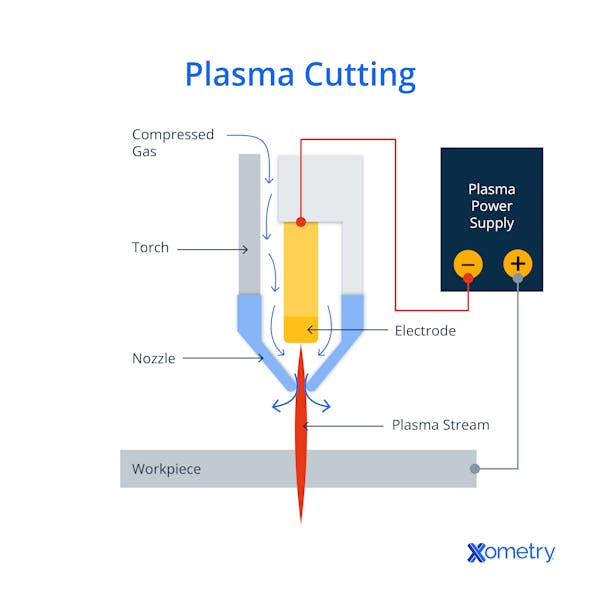

1. Plasma Cutting

Plasma cutting is a cutting process that employs heat to cut through metals or electrically conductive materials such as aluminum, steel, brass, and copper. The thermal cutting process of this technology works by creating an electrical channel of ionized gas, known as plasma. A gas (oxygen or nitrogen) passes through a small nozzle while subjected to a high electrical voltage. The result of this process is an electrical arc that strikes the material of choice to cut it. Plasma can reach temperatures of up to 40,000°F, which melts and cuts through the material.

This method of cutting is faster than conventional cutting methods, including mechanical cutting and oxy-fuel cutting. Various cuts can be made depending on the device's power and the thickness of the materials, ranging from thin sheets to thick sheets. The cost of a plasma-cutting device can vary depending on the power and size of the system, as well as any additional features it may have. On average, the price of a small, portable plasma-cutting system costs about $2,000, while a larger industrial-grade system costs about $10,000. The choice between a laser cutter and a plasma cutter will depend to a large extent on the specific requirements of the application. For instance, lasers are usually more expensive and cut greater levels of detail. On the other hand, plasma can be used to cut thicker metal plates than lasers.

2. Waterjet Cutting

Waterjet cutting works similarly to how erosion, an action of water, removes earth materials from the surface of the ground. It is an accelerated erosion process that utilizes a high-pressure stream of water or a mixture of water and abrasive particles, such as garnet, to cut through materials. This cutting process takes place at a high speed; a high-pressure pump directs the water through a ruby or diamond nozzle to cut the material. During the process, a fast-moving stream of water erodes the material by creating a cutting path or a narrow kerf, usually 0.030" to 0.040" in width.

The cost of a waterjet cutter is dependent on the complexity of the job, the size of the machine, and the thickness of the material being cut. A small waterjet cutter, which costs about $60,000, is available. However, for one to make the most of one's investment, a waterjet cutting machine, which starts at $100,000, is recommended. In certain situations, a waterjet cutter can be an effective replacement, particularly when its versatility in cutting a huge range of materials can be put to advantage.

3. Flame Cutting Or Oxy-fuel Gas Cutting

Flame cutting (oxy-fuel gas cutting) is a thermal cutting process that uses a mixture of fuel gases such as propane, acetylene, and oxygen to heat and cut mild steel or low alloy steel. The heat is produced by the oxy-fuel cutting torch. It is applied to the surface of steel, which quickly achieves a temperature of approximately 1,800°F. The oxidation of the steel begins while a stream of high-pressure oxygen is directed onto the metal to blow away the molten metal, creating a cut or cavity.

An oxy-fuel cutting machine is generally considered to be a more cost-effective option compared to other cutting methods, such as laser cutting, especially for thicker materials. Though an oxy-fuel gas cutter is a reliable and cost-effective machine, it is not the best alternative for all applications. Laser cutting, with its greater precision and faster cutting speeds, can also cut a wide variety of materials—both metals and non-metals. This is not the case with oxy-fuel cutting, which is typically used for cutting only ferrous metals. A good oxy-fuel cutter may cost about $5,400.

4. Mechanical Cutting

Mechanical cutting applies abrasive force or mechanical motion to cut through materials. In this method, materials from a workpiece are removed through shearing or slicing action, rather than melting or vaporizing the material as in some other cutting methods. Depending on the tool or technique being used, the cutting process can vary. Generally, it involves the application of force to a cutting tool that is brought into direct contact with the workpiece or material of choice. The cutting tool may cut with a reciprocating motion, rotating motion, or move along a linear path during the cutting process. This method can be used for cutting a wide range of materials, including plastics, metals, composites, and wood.

In most cases, mechanical cutting can be a more affordable option compared to other methods of cutting, such as laser cutting. Weighing up the pros and cons of mechanical cutting versus laser cutting, laser cutting shines more in its ability to give more precise detail and greater speed. In contrast, mechanical cutting offers advantages in terms of cost and flexibility in certain applications. A hacksaw, reciprocating saw, and circular saw cost around $6–$40, $30–$95, and $150, respectively.

5. Traditional Cutting

Traditional cutting is a primitive or unsophisticated method of cutting. The cutting process utilizes knives, scissors, saws, or shears to separate materials along a desired line or shape. It is a manual cutting process that involves applying force to the workpiece to separate it or create a desired effect. The materials that can be cut with traditional cutting methods depend on the specific tool being used, but they generally include metals, plastics, and wood. Traditional cutting is relatively inexpensive compared to other, more sophisticated methods such as laser cutting. A handsaw can be purchased for $4.

Which Alternative Cutter Is Almost the Same as Laser Cutting?

Plasma cutting and oxy-fuel gas cutting are two alternative cutting techniques comparable to laser cutting. Laser cutting uses a focused beam of light to engrave or cut materials like plastic, metal, and wood. The laser beam heats the material to a point at which it melts, vaporizes, or burns away. As a result, a clear and exact cut is produced. There is a fundamental similarity between the three techniques: they are all thermal cutting techniques. Plasma cutting ionizes gas using a plasma torch to create a hot plasma stream that melts and slices through materials. Another heat-based cutting technique that utilizes oxygen is oxy-fuel cutting.

Which Alternative Cutter Can Effectively Cut Metals?

Waterjet abrasive is an alternative cutter that is useful in all metal-cutting operations. Brass, titanium, and Inconel® (a nickel-chrome-based alloy) are among the metals that waterjet machines can cut relatively easily, in addition to standard materials like aluminum and mild steel.

Which Alternative Cutter Is Easier To Use?

When comparing alternative cutting methods to laser cutting, some are better than others in some aspects, such as ease of use and the versatility of materials that can be cut. Here is a comparison of some alternative cutting methods:

- Plasma Cutting: Plasma cutting can only be used to cut conductive metals and is therefore less flexible than laser cutting. However, due to its less frequent maintenance needs and more straightforward setup, plasma cutting is typically regarded as being easier to use than laser cutting.

- Waterjet Cutting: The most versatile cutting technique is waterjet cutting, which can be applied to almost any material. It is also fairly simple to use.

- Flame Cutting or Oxy-Fuel Gas Cutting: Flame cutting is a simple and cost-effective method for cutting thick metal. However, it is less versatile than laser cutting and requires a skilled person to achieve a quality cut.

- Mechanical Cutting: Mechanical cutting is a straightforward and cost-effective method for cutting thin materials; however, it is less versatile and precise than laser cutting.

- Traditional Cutting: Traditional cutting, compared to other cutting methods, is the most basic and also very accessible. However, it is limited when precision and speed are taken into consideration. It is also not applicable to cutting many types of materials.

“Choosing the right cutting method depends on specific project needs; while laser cutting offers precision, alternative methods may be better suited for certain materials, thicknesses, or budget constraints.”

Frequently Asked Questions About Laser Cutting Alternatives

Which Alternative Cutter Is the Most Affordable?

Generally, traditional cutting and mechanical cutting methods, such as sawing, are the most affordable. Nonetheless, they may not be suitable for all types of materials and may not provide the precision and versatility of other cutting methods. Plasma cutting and oxy-fuel cutting are also affordable options. One of the significant drawbacks of these methods is that they may require more post-processing work. Waterjet cutting is a more expensive option, but it offers greater precision and versatility in cutting a wider range of materials, including metals, plastics, and other materials.

When To Use Alternative Cutters?

Though a laser cutter is a perfect option when it comes to cutting many different materials, maintenance issues arise with all machinery, and in other cases, it may not be within one's budget. Whatever the case, several alternatives exist that can serve as suitable replacements for laser cutting. If a laser cutter develops a fault, alternative cutters can be used as a temporary solution to continue production until the laser cutter is repaired. This can help minimize downtime and prevent production delays. Furthermore, there are certain materials for which laser cutting may not be the best option. In that case, it may be necessary to explore other options to realize the best return on plant investment.

Can I Make a DIY Cutter?

Yes, it is possible to create a DIY cutter. There are various types of cutters, including wood cutters, metal cutters, and paper cutters. For each type, the materials and tools required may differ. Online tutorials are available to guide you through building a DIY cutter. However, precautions and safety protocols should be observed during the process, as working with sharp blades can be hazardous.

Summary

This article presented alternative cutters to laser cutting, explained each of them, and discussed how each work and which applications they are most useful for. To learn more about laser cutting alternatives, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including laser cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Copyright and Trademark Notices

- Inconel® is a registered trademark of Special Metals Corporation

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.