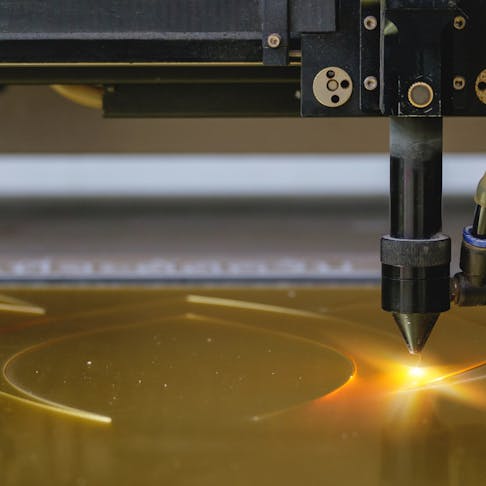

Laser cutting is a versatile technology for creating precise but repeatable profiles. The success of laser cutting depends heavily on the material to be cut. This is particularly the case with plastics, where a wide variety of chemistry can give different results with different plastic materials. While some plastics are unsuitable for laser cutting, many others perform very well with this process. Below, we describe the 10 best plastics for laser cutting:

1. Acrylic

Acrylic, commonly known as PMMA (polymethyl methacrylate), is an ideal material for laser cutting. A common trade name for acrylic is Plexiglas®. It is lightweight and strong for its weight, with greater impact resistance than glass but significantly lower impact resistance than polycarbonate. Acrylic cutting is widely used for safety glass and signage, and even for items of furniture.

Laser cutting acrylic can be done to give a laser-polished edge. There is some risk of flame-ups, but generally, cutting acrylic is tolerant to different settings and will consistently give a clean laser cut.

2. Styrene

Polystyrene (PS), including high-impact polystyrene (HIPS), is commonly sold as ‘styrene’ sheets for models and appliances; it is inexpensive, available in thin sheets, and generally more brittle than acrylic. Styrene is very common in toys such as hobby models and is also used in home appliances.

Styrene is a good material for laser cutting as it has a low melting point and melts easily in the path of the laser. However, the low melting point also means that cuts cannot be too intricate or close together, as the edges will melt and lose detail. Styrene sheets can warp if they get too hot.

3. Kapton® Tape

Kapton® tape is a thin film (only a few thousandths of an inch thick) of a polymer called polyimide, with an adhesive coating on one side or both. It is most commonly used in the manufacture of electronics and spacecraft. The reasons for these applications include excellent electrical insulation and stability across a wide temperature range; standard Kapton® films have low thermal conductivity. Special MT/MT+ grades are engineered to be thermally conductive for heat-spreading or interface uses. It can withstand the temperatures of soldering.

It is an ideal material for laser cutting because it is very thin and is a thermoset plastic with high-temperature resistance. When laser cutting Kapton®, the material in the direct path of the laser absorbs the optical energy and is vaporized. The adjacent material conducts the heat well but shows some carbonization. This heat-affected zone is very narrow, and the carbonization can be easily removed with a solvent. Therefore, Kapton® tape can be laser cut in complex and precise patterns, ideal for mating with circuit boards.

4. Nylon

Nylon is a generic name for a range of thermoplastic polyamides. It is commonly available as a filament woven into a thin fabric, originally under the trademark of Perlon®. It has high strength and toughness. It is used in textiles such as rainwear, lingerie, and parachutes. Thicker filaments are also available for applications such as fishing lines.

Nylon fabric generally laser-cuts cleanly, and the heat can seal the edge to reduce fraying, though results depend on fabric construction and settings.

5. High Density Polyethylene (HDPE)

High-density polyethylene is a widely used plastic due to its cost-effectiveness and versatility. It has a high strength-to-weight ratio and good moisture and chemical resistance. HDPE can be formed into a wide variety of shapes, including pipes, containers, and sheets.

HDPE melts readily under a CO₂ laser and tends to produce melty, messy edges or warping, especially in thicker stock; it’s generally not recommended for clean laser cutting results. However, due to its relatively low melting point, care must be taken that high power or multiple cuts close together do not cause localized melting and an uneven edge.

To learn more, see our guide on High-Density Polyethylene.

6. Polypropylene (PP)

Polypropylene is a thermoplastic polymer that has excellent chemical and heat resistance. It is also rigid with a high impact resistance. PP has wide industrial applications, but can also be used in domestic and household containers.

Polypropylene can be laser cut, but its low melting point means a wider kerf, and edge melt or burrs are common, so process control is important.

7. Polyethylene (PE)

Polyethylene is the most commonly produced plastic globally, and it has many different forms and varieties. Some examples include the relatively rigid high-density polyethylene (HDPE) and the flexible, lightweight linear low-density polyethylene (LLDPE). These variations provide many different applications for plastic, but its largest use is in films for packaging, including food wrapping and plastic bags. Polyethylene tends to have a waxy, soft surface.

PE can be cut in thin gauges, but melting and a wide kerf are common; discoloration/soot is uncommon because PE tends to melt rather than char.

8. ABS (Acrylonitrile Butadiene Styrene)

ABS is an opaque thermoplastic blend of three other polymers: acrylonitrile, butadiene, and styrene. Variations of ABS can be manufactured by varying the blend, but generally, ABS is rigid and durable with high impact resistance. It can be easily formed into different shapes, and therefore, has a wide application in wear-resistant parts, including motor parts, keyboard keys, and equipment housings.

ABS is not recommended for laser cutting because toxic and irritating decomposition products can form (including hydrogen cyanide under combustion), and the plastic melts, chars, and can ignite. If processed, use enclosed fume extraction with filtration rather than venting directly outdoors; polished-edge finishes are unlikely. Generally, fine cuts cannot be made in ABS as the material tends to heat up and warp.

9. Two-Tone Acrylic

Two-tone acrylic is a variation of acrylic that laminates one color of a thin acrylic sheet onto another core acrylic sheet of a different color. This has the same useful material properties as standard acrylic, but is more visually striking, especially when engraved. Engraving two-tone acrylic through only the thinner top layer, to reveal the color of the bottom layer, provides a visual contrast that is valuable in signage and promotional materials.

Two-tone acrylic laser cuts and engraves like standard cast acrylic, and can yield polished edges; ensure settings avoid overheating the thin cap layer during engraving.

10. Mylar®(Polyester)

Mylar® is the trade name for thin polyester sheets. These sheets are usually transparent, flexible, and durable. Mylar® also has excellent moisture and chemical resistance, and a very good range of temperature resistance. As such, this plastic finds good application in food packaging. Polyester/Mylar® is widely used for laser-cut stencils; 200-250 μm sheets are common for durable, flexible stencils.

What Are the Guidelines for Laser Cutting Plastics?

Plastics are generally cut with a CO₂ laser. Cut quality depends on wavelength and material: for several films and polymers (e.g., PET, PC, some PP labels), 9.3-10.2 μm can cut cleaner than 10.6 μm. Many clear plastics absorb 1.06 μm poorly, so fiber lasers are usually not recommended for cutting plastics, though they can mark some plastics (often with additives), and UV lasers frequently give the highest-contrast marks on resins.

Cutting plastic with a laser is generally easier with a medium to high-powered CO₂ laser. Settings are material-specific. A single, higher-speed pass can reduce heat-affected melting on many plastics. For acrylic, higher pulse frequency/PPI promotes ‘flame-polished’ edges, whereas on materials prone to charring (e.g., wood), lower frequency is preferred.

Plastics that cut well should absorb the chosen wavelength efficiently, produce minimal hazardous by-products, and have low ignition risk. Some plastics release toxic or corrosive fumes when laser cut (e.g., PVC releases hydrogen chloride (HCl) gas) and are unsuitable.

What Should I Consider When Choosing a Plastic for Laser Cutting?

When choosing plastic for laser cutting, start by defining the end product’s requirements. The final product (after laser cutting) will dictate the properties of the plastic that you will need to use. These could be properties such as whether the plastic should be transparent or opaque, whether it should be flexible or rigid, and whether it must be tough or could be brittle to an acceptable degree.

You should also consider the plastic’s appearance, such as its color or surface finish. The affordability of plastic will also be important.

Once these things have been considered, there will likely be more than one potential plastic that may be suitable. Then, the ease of laser cutting each plastic can be considered.

In practice, selecting the right plastic for laser cutting is not just about aesthetics or precision, it often determines how fast, safe, and economical the manufacturing process will be.Audrius ZidonisPrincipal Engineer at Zidonis Engineering

How Do I Choose the Right Plastic for My Laser Cutting Project?

There are many plastics available for projects, and the choice can be daunting. Choose the right plastic for your laser cutting project by taking this approach:

- List the physical properties that are important to the success of the final project output. These could include: transparent or opaque, colored or white/clear, heat resistance required or not, flexible or rigid, and heavy-duty application requiring high impact resistance or not.

- Consider the possible plastics that are easily available to you and reasonably affordable.

- Think through the processing steps that would be required to complete your project. If laser cutting is the main step, select a plastic based on the ease and edge quality of cutting with a laser. If further processing is required, such as machining or attaching to another surface, another plastic may be better suited.

Common FAQs on Plastics for Laser Cutting

Which Plastics Are the Worst for Laser Cutting?

PVC (polyvinyl chloride) must not be laser cut because it releases hydrogen chloride (HCl) gas and corrosive chlorine compounds that can damage optics and harm operators.

Polycarbonate can sometimes be laser cut in thin sheets, but it tends to burn, discolor, and emit toxic fumes, so it is not recommended for CO₂ laser cutting. Specialized laser systems (e.g., UV or 9.3 μm CO₂) may reduce discoloration, but charring and yellowing are common. Expanded polystyrene (Styrofoam™) is highly flammable and can ignite or melt excessively under a laser, producing styrene vapors; it should not be laser cut.

What Materials Should Not Be Laser Cut?

Materials unsuitable for laser cutting include:

- Fiberglass (contains epoxy and glass fibers that emit toxic fumes)

- Carbon fiber (epoxy binder burns and releases fumes)

- Materials containing halogens (fluorine, chlorine, or bromine, such as PTFE or PVC)

- Epoxy and phenolic resins (produce hazardous phenols and formaldehyde)

- Glass (cannot be cut with CO₂ lasers, only engraved)

To learn more, see our guide on the Types of Bad Materials for Laser Cutting.

How Can I Test a Material To See if It Will Cut Well With a Laser?

To test whether a material is suitable for laser cutting, start with a small sample and a standardized test pattern that varies laser power, cutting speed, and pulse frequency. This helps you observe how the material behaves under different conditions. During the test, pay close attention to the color of the smoke, any unusual odors, melting, bubbling, or residue on the surface. These signs can indicate that the material produces hazardous fumes or does not vaporize cleanly. A compatible material will typically produce a consistent, smooth cut with minimal discoloration, warping, or edge residue. Always perform the test using proper ventilation or fume extraction to ensure safety, since some materials can emit toxic gases even in small quantities.

Is Plastic Easier To Cut Than Wood?

In many cases, plastics such as acrylic or polyester are easier to cut cleanly than wood, which tends to char and discolor. However, some plastics (e.g., HDPE, PP, ABS) melt rather than vaporize, making them harder to cut cleanly than most woods. Wood also has a higher risk of catching fire when laser-cut. It can also warp. These same problems can occur when laser cutting with specific plastics, but there are many plastics easily available that do not have these risks.

Summary

This article presented the best plastics for laser cutting, explained each of them, and discussed their various applications. To learn more about plastic laser cutting, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including Plastic Laser Cutting services and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Copyright and Trademark Notices

- Plexiglas® is a trademark of Röhm GmbH.

- Kapton® is a trademark of DuPont Electronics, Inc.

- Perlon® is a trademark of Perlon-Monofil GmbH.

- Mylar® is a trademark of DuPont Teijin Corporation.

- StyrofoamTM is a trademark of Dow Chemical Company.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.