M2 measurement is a simple way to understand and measure the quality of a laser. Essentially, M2 measurement needs the beam waist—the narrowest part of the beam at its focal point—to be found. However, the position of this beam waist is not always clear. Multiple measurements are needed around the focal point to ensure an accurate waist evaluation. From this beam radius and its position, you can calculate M2 and the relative quality of your laser. Listed below are the steps required to take these beam radius measurements:

1. Start With a Collimated Beam

It is crucial for an M2 measurement to start with a collimated beam. Collimation of light is done by using a device that ensures all rays that pass the device are parallel. This collimating device is usually a lens with a specific geometry suited to the light source, to provide parallel rays.

2. Use an Aberration-Free Lens To Focus the Laser Beam

To establish an M2 measurement, it is important to use a lens of known focal length. Therefore, this lens must be aberration-free—meaning it is free from blemishes and inaccuracies that would introduce deviations into the focus of the beam.

3. Measure the Diameter of the Beam at Various Positions Around the Focal Point

The beam waist is the minimum beam radius. This will be the beam radius at the focal point of the laser. However, due to inaccuracies in field measurements, it is not possible to precisely measure this beam waist at a single point. Rather, according to ISO 11146 for testing laser beams, it is necessary to take multiple measurements around the known focal point and find the minimum of these measurements to establish the beam waist.

At least 10 data points of beam radius should be taken. About half of these points should be taken close to the focal point (within one Rayleigh length of the focal point), and the other half should be taken further away from the focal point (more than two Rayleigh lengths away). These measurements will be of the laser beam width in both the x direction and the y direction (as the beam may not be perfectly circular).

4. Use the Regression Equations Detailed in the ISO Norm to Fit a Hyperbola to Your Data Points for Both the X and Y Axis

The reason for taking data points at different distances from the laser beam focal point is so that a hyperbola can be fitted closely to the data that is plotted. The ISO norm details the regression equations to be used to fit this hyperbola. The data points should be plotted showing the beam radius against the distance from the lens. The hyperbola will show the minimum beam radius, and therefore give the beam waist. A hyperbola should be plotted for both the x-direction and the y-direction.

5. Extract the Values for, w0, zR, and M2 for Each Axis

Using the hyperbola fitted to your data points, the minimum beam radius is easily shown as the beam waist (w0). The Rayleigh length (zR) can be calculated as the distance at which the laser radius is greater than the beam waist by a factor of the square root of 2. For a circular beam, this is the distance at which the cross-sectional area is twice the minimum at the beam waist. These values can be determined for a laser beam in both the x-direction and the y-direction.

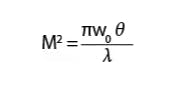

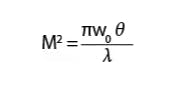

Finally, with the beam waist known, the M2 factor can be determined by a calculation. It is calculated by using the following equation:

M2 factor calculation.

Why Is It Important To Understand Laser Beam Quality?

It is important to understand laser beam quality because it has an impact on the quality of the cut the laser will give. Laser beam quality is a measure of how precisely the laser can be focused—a low-quality laser will not be focused into a small, intense point, but rather be more widely distributed. This will give a lower intensity at the cutting point, and create a wider cut. For more information, see our guide on Laser Beam Quality.

What Is the M2 Factor?

The M2 factor is also called the beam quality factor, or the beam propagation factor. It is a measure of how closely a laser beam resembles a Gaussian beam. The ideal Gaussian beam is brightest in the center and its intensity follows a normal distribution in each direction away from the center.

The M2 factor is calculated by the measurement of a laser’s beam waist—the width of the beam at its narrowest point. This is determined by beam radius measurements at different distances around the focal point. Once the beam waist w0 is known, the M2 factor is calculated by the following formula:

M2 factor calculation.

How Important Is the M2 Factor for Laser Beam Quality?

The M2 factor is fairly important for laser beam quality. It is a common, well-defined (by ISO 11146) means of communicating how close to ideal the measured beam is. The M2 factor is important because it provides information on how precisely a beam can be focused, and therefore its effectiveness in applications such as laser cutting.

However, there are other parameters that can provide further information about beam quality (such as Power in a Bucket or the Strehl ratio), so M2 measurement is not the only way to communicate laser beam quality.

What Are the M2 ISO Norm Rules for Measuring the Laser Beam Diameter?

The measurement of beam quality by the M2 factor is standardized in ISO 11146. This international standard sets out some rules for taking beam measurements, to ensure sufficient accuracy and repeatability. These rules are particularly important if you are using a CCD or CMOS sensor for the beam diameter and are listed below:

- Measure a Region Three Times Larger Than the Diameter: To be sure that the beam diameter is fully measured, the region of interest that the sensor is measuring should be at least three times the expected beam diameter.

- Have at Least 10 pixels Within the Beam's Diameter: For a reasonable resolution of the diameter measurement, a minimum of 10 pixels of the sensor should be within the beam diameter. If the beam diameter is smaller than 10 pixels of the sensor, a different sensor should be used for accurate results.

- Use the D4σ Definition for Diameter: In a Gaussian beam, the cutoff for the outer edge of the beam can be defined by the D4σ. This is the distance that is four standard deviations away from the peak intensity at the center. This definition of the edge of the beam diameter must be applied in your measurement.

- Remove Background Noise: Outside interference from other electromagnetic sources should be avoided when taking a measurement. Shield the sensor from other noisy sources, or isolate those sources during measurement.

What Are the Types of Equipment To Measure Laser Beam Quality?

The types of equipment to measure laser beam quality are:

1. Lens

A lens of known properties is used to focus the laser beam at a specific focal length. This allows the position of the beam waist to be known so that the beam diameter can be measured at the correct distances to establish the M2 measurement.

Clear plastic ruler.

Image Credit: Shutterstock.com/Joey Chung

Is M2 the Only Way To Measure the Quality of a Laser Beam?

No, M2 is not the only way to measure the quality of a laser beam. It is a convenient measure as it is a single number, but it cannot completely convey all the details of a laser beam’s quality. Other measurements of laser quality include the beam parameter product (BPP), the power in the bucket (PIB), and the Strehl ratio.

The BPP is related to the M2 factor and is also described by ISO 11146 for laser beam quality. It is the product of the beam waist and the half-angle beam divergence. The approach for PIB measurement is to describe the fraction of the laser’s total power that is incident within a defined cone—the “bucket”. This is a more direct indication of the laser quality for cutting purposes, as it relates to the ability to create a small, intense spot on a material. The Strehl ratio takes a different approach to beam quality and is based on the root mean square of the transmitted wavefront error.

Is Measuring Laser Beam Quality Harmful?

No, measuring laser beam quality is not harmful so long as standard precautions are taken. The most crucial is the wearing of Personal Protective Equipment (PPE), particularly laser safety goggles. These goggles should be rated to block the wavelength of the laser being measured. There is the risk of eye exposure to laser energy if the proper laser alignment is not complete, or if the M2 measuring equipment is used incorrectly.

Is a Laser Beam the Same as a Gaussian Beam?

A Gaussian beam can refer to an ideally distributed laser beam, but it is not necessarily the same thing. A Gaussian beam is simply a beam that exhibits a normal distribution in each direction. Its intensity is the greatest in the center, with a normal distribution of lowering intensity at concentric distances away from the center. This is an ideal laser, also referred to as TEM00.

However, real lasers do not have this ideal Gaussian distribution but can be compared to it as a quality parameter. That is the M2 factor (or beam quality factor) of a laser—the closer the M2 of a laser is to 1, the more closely it resembles a Gaussian beam. For more information, see our guide on Laser Cutting.

Does Knowing the Laser Beam Quality Help When Laser Cutting?

Yes, knowing the quality of a laser beam does help when laser cutting. The quality of the beam will give you an indication of how precisely the laser can be focused. This dictates how wide the kerf of the cut will be. Knowing the quality of the laser beam also allows the intensity of the beam at its incidence to be understood. A lower-quality beam will have a lower intensity where it strikes the material, as the optical energy is spread over a wider surface. This may influence how easy it is to start and maintain the cut, as well as what power setting to use.

Does Laser Beam Quality Affect the Laser Settings?

Yes, laser beam quality will affect the settings you use for your laser cutter. The quality of a laser beam indicates how well (how small and precise) it can be focused. This determines the size of the laser’s incidence on the material to be cut, as well as its intensity at that point.

If a low-quality laser is in use, you will know that the kerf of the cut will be relatively wide and that the energy of the laser is spread over a wider area, lowering the intensity. This lower intensity will prompt a higher power setting to be used for laser cutting. It will also mean that a slower cutting speed will be necessary in order to consistently maintain the cut through the material.

Summary

This article presented measuring a laser beam quality with M2 measurement, explained what they are, and discussed the various steps and calculations involved. To learn more about measuring a laser beam quality, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.