Surface Finishes to Enhance Your Sheet Metal Parts

Surface finishing is critical when your parts are visible or cosmetic rather than deep inside an assembly. Parts fresh off the waterjet or laser often have a burr on their bottom face, marks from handling, frosting near the cut line from overspray, and vestigial tabs from being held in place during cutting. Applying a finishing process to parts post-cutting will help you get parts that need minimal cleanup before installation.

Xometry offers an expansive array of finishing options for your custom parts. Read on to see examples of the mechanical finishes available for sheet cut and sheet metal parts.

As-Cut Surface Finishes

This process is the most common option for parts that will not be seen or handled, or if you will be applying your finish once you receive the parts from Xometry. As-cut flat sheet cut parts may not have a consistent cosmetic appearance. For example, overspray from the waterjet near the cut line, especially at pierce points and on the bottom face, may show a visible halo. There may be minor marks from handling on the top and bottom faces and from exposure to water. Similarly, lasers can discolor metal around the cut edges. Some metals also have mill marks from the manufacturer, which look like printed text.

On smaller parts where one or both dimensions are less than four inches, we have to tab the part to the sheet during cutting to keep them from ending up at the bottom of the waterjet tank. In these instances, we allow the techs to pop them off the sheets or ship you the sheet with the parts still attached. Tabbed parts are shipped still attached if the individual parts are so small they could easily get lost in packaging. If you want your parts to ship separated from the sheet, with the tabs ground down, you will want to select one of the finishing options below or select "Separated with Tabs Removed".

Gallery: Standard, As-Cut Surface Finishes

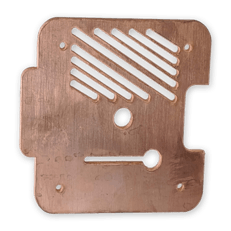

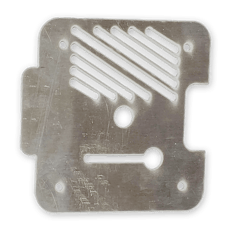

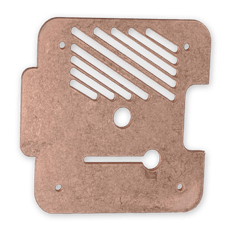

As-Cut Copper Sheet

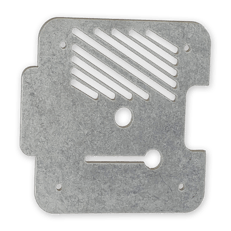

As-Cut 304 Steel Sheet

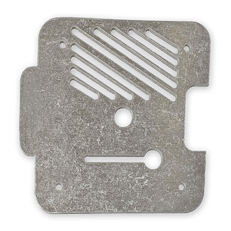

As-Cut Aluminum Sheet

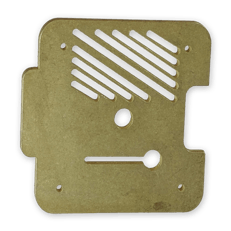

As-Cut Brass Sheet

As-Cut Low Carbon Steel Sheet

Bead Blast Finish

Bead blast finish removes burrs and surface imperfections while providing a fine grain finish across the entire part. We apply this finish by blasting the parts with a high-pressure stream of tiny glass beads. This option is a perfect match for waterjet cutting, as the surface resembles the cut edge produced by the garnet from the waterjet, meaning that the finish on the faces and cut edge are closely matched. Bead blast finish is an excellent option if you plan to paint your parts post cutting as the even "tooth" of the surface allows paint the nooks and crannies it needs to get a good hold of the surface. It is also a great option when looking for a matte finish. Before anodizing, bead blast and other matte finishes are ideal surface preparations, creating a nonreflective matte appearance.

The parts must fit in a blast cabinet to apply the bead blast finish; typically parts less than 24 inches in both height and width should fit. We recommend bead blast for parts over one square inch; any smaller, and the parts will be hard to hold and it will be difficult to apply the finish evenly. Parts given a bead blast finish will be removed from their source sheet and have their tabs ground off to make the edges as clean as possible.

Gallery: Bead Blast Finish

Bead Blasting Equipment

Bead Blasted Copper

Bead Blasted 304 Stainless Steel

Bead Blasted Aluminum

Bead Blasted Brass

Bead Blasted Low Carbon Steel

Media Tumbled Finish

Media tumbling is an inexpensive way to remove burrs, reduce surface marks, and produce an even texture on smaller parts. We place parts in a vibratory tumbler with ceramic abrasive media. This combination of movement, water, and media puts a smooth and even surface all over the part's surface. Tumbling is excellent if you want to prep small jewelry parts or electrical connectors before further polishing or soldering. It is also a great way to process small parts for production work.

Suitable parts for media tumbling are typically smaller than four inches in both height and width. Also, the stock material must be strong enough to handle the tumbling process. We recommend stainless steel parts be 0.030" thick or greater for tumbling. For tumbled aluminum and other non-ferrous metals we recommend they be at least 0.045" thick. With a media tumbled finish, our techs will also remove any tabs by grinding so that they do not appear on the finished part.

Gallery: Media Tumbled Finish

Vibratory Media Tumbler

Copper With Tumbled Finish

304 Stainless Steel With Tumbled Finish

Aluminum With Tumbled Finish

Brass With Tumbled Finish

Low Carbon Steel With Tumbled Finish

Sanding Random (Swirl) Finish

Sanding Random (Swirl) parts are finished on both the top and bottom faces with a powered non-woven abrasive pad in a random orbital pattern. Many of our signage clients use this finish for signs as the all-over brushed finish looks good in a wide variety of locations, and the texture left behind by the abrasive pad also provides a good "tooth" for paints to hold. This finish removes all light surface scratches, mill marks, and burrs. Orbital sanding finishes are best for parts above six inches. Tumbling (see below) is recommended for smaller parts. Like bead blast, sanding random swirl finishes are excellent for preparing surfaced before anodizing to create a matte non-reflective appearance.

Note: This finish can be requested with the "Other" finish option when quoting.

Gallery: Sanding Random (Swirl) Finish

Orbital Sander

Swirl-Finished Copper

Swirl-Finished 304 Stainless Steel

Swirl-Finished Aluminum

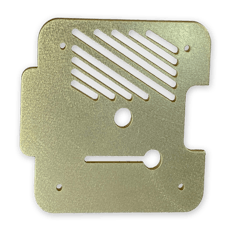

Swirl-Finished Brass

Low Carbon Cold Finshed Steel With Random Swirl

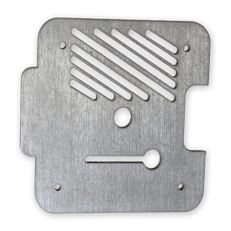

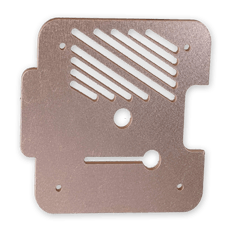

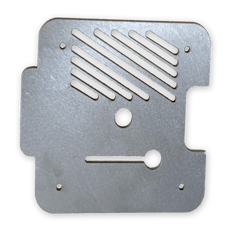

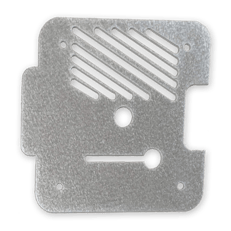

Linear Grain Sanded Finish

Also called a brushed or Timesaver finish, Linear Grain finishes are created by sanding both sides of the metal with a non-woven abrasive on a belt sander or Timesaver machine. This produces a brushed look with uniform, parallel lines. While the result is attractive and suitable for most applications, it is not a perfectly consistent #4 standard finish, since the process involves manual operation. By default, sanding follows the natural grain of the material. If a custom grain direction is required, please include this on your drawing.

Note: This finish can be requested with the "Other" finish option when quoting.

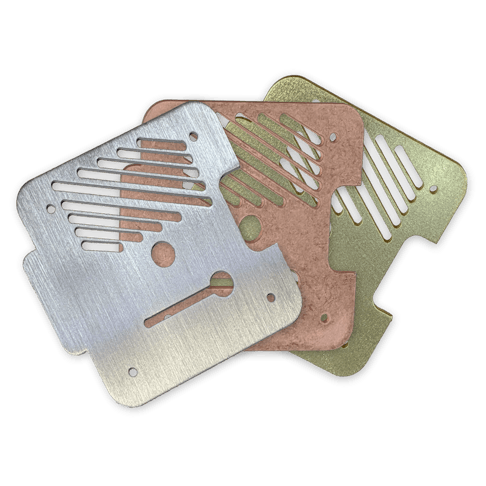

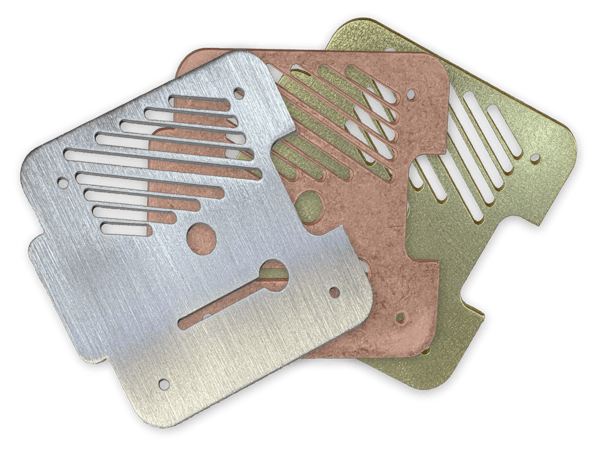

Gallery: Sanding with Grain (Linear) Finish

Belt Sander for Linear Sanding

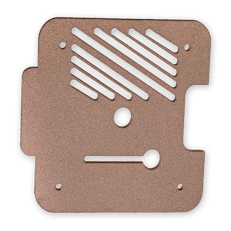

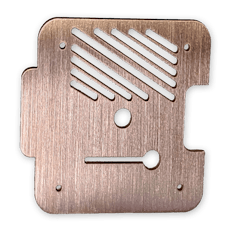

Linear Grain Sanded Copper

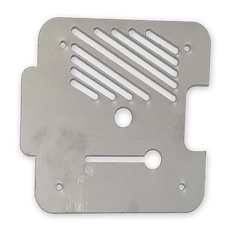

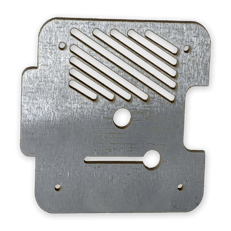

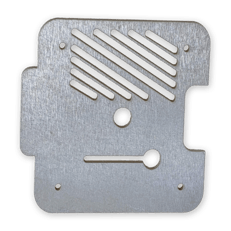

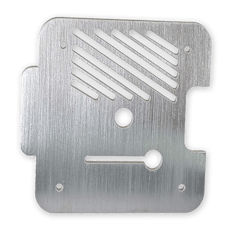

Linear Grain Sanded 304 Stainless Steel

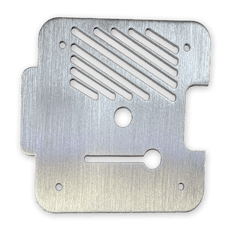

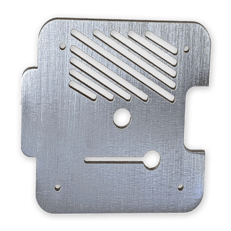

Linear Grain Sanded Aluminum

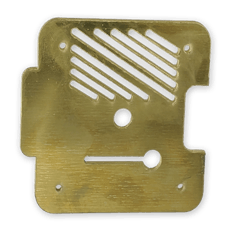

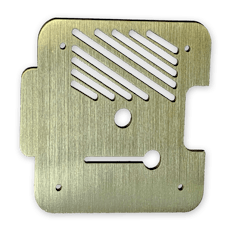

Linear Grain Sanded Brass

Linear Grain Sanded Low Carbon Steel

Additional Finishes

These are just a few of our post-processing options for sheet cut and bent sheet metal parts. See our metal finishes gallery for more metal finishing options. Like our other services, Xometry can offer turnkey finishing services like anodizing, chem-film, metal plating, powder coating, heat-treating, passivation, and even multiple custom finishes. These can be specified directly through our Xometry Instant Quoting Engine.

Handling and Maintenance of Metal Finishes

One aspect of metal finishing you should also be aware of is how reactive the materials you are ordering are and how mill materials are shipped. Stock materials are kept as clean, dry, and scratch-free as possible when handling; however, material suppliers seldomly provide pristine sheet materials. This is why the finishes we covered here are excellent options to consider for your parts.

Waterjet cutting uses abrasive materials and a cutting method that is not conducive to pristine mirror-polished sheets or sheets with coatings. Most suppliers process mill sheets with a thin layer of oil to minimize oxidization. Abrasive finishes remove protective coatings, which lead to oxidation, tarnish, or dulling. While not as challenging to remove as tarnish, stainless steel parts will also show fingerprints from handling.

Most non-abrasive jewelry cleaners will remove the tarnish on copper and brass materials. Denatured alcohol or other similar solvents are great for removing fingerprints from stainless steel. 000 steel or bronze wool helps scrub off oxidation on metals. Just be sure to work in the direction of the finish applied. A dab of clear microcrystalline wax worked into the surface of your part can keep it resistant to oxidization. Some metalworkers also suggest clear polyurethane and paste waxes as options for keeping oxidization away.