Laser cladding is an advanced manufacturing technique that involves the deposition of a protective or functional layer onto a substrate using a laser beam. Compared to conventional cladding techniques, laser cladding offers precise heat control through high-energy lasers, minimizing distortion and improving metallurgical bonding. Metals, alloys, ceramics, and composite materials can all be applied as cladding. Due to their adaptability, coatings can be customized to give their host part specific qualities like improved wear resistance, corrosion protection, or thermal conductivity.

Numerous industries, including aerospace, automotive, oil and gas, and tooling, use laser cladding. It is used to replace worn or damaged parts, apply protective coatings to increase part longevity, and in some cases, build near-net-shape features when integrated into additive manufacturing systems. Laser cladding has become a cutting-edge manufacturing technology due to its remarkable precision and flexibility. This article will discuss the procedure, categories, uses, and characteristics of laser cladding.

What Is Laser Cladding?

Laser cladding is a manufacturing process that deposits a metallic material onto a surface using a laser beam as the heat source. The substance is melted and fused to the surface, and depending on the material applied, it can offer enhanced properties such as improved hardness, wear resistance, or corrosion protection. Industries like aerospace, automotive, and tooling commonly use this method.

What Is the Other Term for Laser Cladding?

Laser cladding is often referred to as laser metal deposition (LMD), though LMD is a broader term that includes various laser-based deposition techniques. LMD refers to the same process of applying a coating, adding material to a component (deposition), and fusion of materials onto a surface using a laser beam.

What Is the Origin of Laser Cladding?

Laser cladding can be traced back to the late 1970s when lasers were introduced to the surface coating industry. However, conventional coating techniques were typically preferred because lasers were so expensive. The popularity of laser cladding has grown, however, with the development of more accessible laser sources and the investigation of new applications for lasers.

How Does the Laser Cladding Process Work?

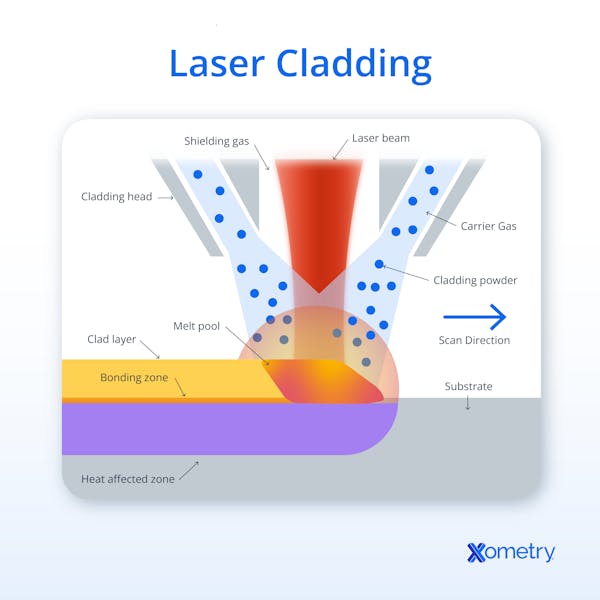

Laser cladding works by depositing material, typically metal powder or wire, onto a substrate using a laser beam as the heat source. The laser simultaneously melts the feedstock and a thin layer of the substrate, allowing the molten material to fuse and form a metallurgical bond. The process allows precise control of coating thickness, composition, and surface characteristics.

What Is the Purpose of Laser Cladding?

The purpose of laser cladding is to repair worn or damaged surfaces and to apply protective coatings that enhance performance and durability. The process offers precise control over material deposition and bonding.

Why Is Laser Cladding Important?

Laser cladding is important because it allows precise repair, enhancement, and protection of surfaces. Compared to traditional methods, it produces a smaller heat-affected zone, reduces material waste, and supports a wide range of compatible materials. Its precision and adaptability make it a valuable manufacturing and repair method.

What Are the Uses of Laser Cladding?

Among the applications for laser cladding are:

- Surface restoration and repair of worn or damaged components.

- Wear- and corrosion-resistant coating.

- Thermal barrier coating for high-temperature applications.

- Enhancement of surface properties like hardness and friction resistance.

- Near-net-shape buildup of features in hybrid manufacturing systems.

- Additive manufacturing when integrated into directed energy deposition (DED) processes.

Laser cladding is a valuable process for restoring and upgrading critical components without starting from scratch. From a design perspective, it offers a cost-effective way to extend part life, especially when surface properties matter more than bulk material selection.

What Are the Different Types of Laser Cladding?

The various kinds of laser cladding methods include:

1. Powder-Fed Laser Cladding

Powder-fed laser cladding is an additive manufacturing style that involves melting and depositing powdered material onto a substrate using a laser. Given that the material is delivered in powder form, it differs from the wire-fed style of laser cladding. It can be applied to coating, repair, and prototyping tasks.

2. Wire-Fed Laser Cladding

Wire-fed laser cladding uses a continuous metal wire as the feedstock, which is melted by a laser and deposited onto a substrate. It produces less material waste than powder-fed systems and often results in higher material utilization efficiency. Typical applications include surface repair and coating, though wire-fed systems are generally less suited to fine or complex geometries compared to powder-based systems.

3. Direct Energy Deposition (DED) Laser Cladding

Direct Energy Deposition (DED) is a broader additive manufacturing category that includes laser cladding. In DED laser cladding, material—usually in powder or wire form—is fed into a laser-induced melt pool on the substrate. It is used for part repair, feature addition, and near-net-shape manufacturing. Unlike powder bed fusion, DED enables material addition to existing components.

What Type of Laser Is Used in Laser Cladding?

For the deposition process, laser cladding typically uses a high-power solid-state laser. The following is a list of laser types used in laser cladding:

1. Fiber Lasers

Fiber lasers generate laser beams using optical fibers and are known for their efficiency and reliability. To learn more, see our All About Fiber Lasers guide.

2. Diode Lasers

Diode lasers emit laser beams through semiconductor diodes and offer precise control in a compact package.

3. CO₂ Lasers

Carbon dioxide (CO₂) lasers produce laser beams using a gas mixture. While less commonly used for laser cladding due to their longer wavelength and limited absorption in metals, they can be suitable for processing larger surface areas in specific applications.

4. Nd:YAG Lasers

Neodymium-doped yttrium aluminum garnet (Nd:YAG) lasers use a solid-state crystal to produce beams in the near-infrared range. They are versatile but have largely been superseded by fiber lasers in many cladding applications due to better beam quality and efficiency.

What Are the Different Applications of Laser Cladding?

Different industries use laser cladding in various ways. Here are a few examples of typical applications:

1. Aerospace Industry

The aerospace industry uses laser cladding to fix broken or worn-out parts, enhance surface qualities, and apply protective coatings to increase part durability and performance.

2. Automotive Industry

Laser cladding is used in the automotive industry to restore or repair worn-out engine parts like cylinder heads and camshafts. This improves their lifespan and functionality.

3. Medical Industry

Laser cladding finds value in the medical field for manufacturing and repairing medical implants and prosthetics. It allows for the precise deposition of biocompatible materials and enhances the longevity and functionality of these devices.

4. Oil and Gas Industry

The oil and gas sector uses laser cladding to repair and safeguard drilling equipment, valves, and other crucial pieces of machinery that are subject to challenging operating conditions. It extends their service life and limits downtime.

5. Energy Industry

In the energy industry, laser cladding is used to refurbish and repair turbine blades, boiler parts, and other high-temperature, high-stress components. It improves their resistance to corrosion, wear, and thermal fatigue.

6. Mold and Die Industry

The mold and die industry uses laser cladding to modify and repair broken or worn-out molds and dies. Since lasers can deposit materials precisely, they reduce the need for extensive rework and increase productivity.

What Are the Key Parameters that Affect the Quality of a Laser Cladding?

The important factors that influence laser cladding quality include substrate type, surface preparation, laser power, scanning speed, powder or wire feed rate, material composition, and shielding gas flow. The cladding geometry, bonding, porosity, and surface finish are all directly impacted by these parameters. They must be optimally controlled and adjusted to achieve desired clad quality and properties.

How Does Laser Power Affect the Laser Cladding?

Higher laser power improves the melting and bonding of cladding material, leading to better adhesion. It permits thicker layers and deeper penetration. However, it must be properly tuned; too much power can result in thermal damage, whereas too little results in weak bonding. The appropriate power level is essential for the best cladding quality.

How Does Laser Speed Affect the Quality of Laser Cladding?

Faster laser speeds produce layers that are thinner and less diluted. Better control of dilution and bonding quality is possible at slower speeds. Low speeds expose the item to thermal damage while high speeds result in incomplete melting. The ideal cladding quality depends on selecting the proper speed.

What Materials Are Used in Laser Cladding?

It is possible to use many different materials with the adaptable process of laser cladding. Among the popular options are:

- Metal alloys such as stainless steel, nickel-based alloys, titanium alloys, cobalt-chromium alloys, and aluminum alloys.

- Hard ceramic phases such as tungsten carbide, alumina, and zirconia are often used in composite coatings but are not typically laser cladded alone.

- Metal matrix composites are composed of metal and ceramic particles dispersed in a metal matrix.

- Tool steels are used for enhancing wear resistance and tool life.

Can Metals Be Used in Laser Cladding?

Yes, laser cladding can be done with metals. These materials, such as stainless steel and nickel-based alloys, are valued for their mechanical strength and ability to form strong metallurgical bonds.

Is It Possible To Use Alloy in Laser Cladding?

Yes, many pre-existing alloys can be used in laser cladding. These alloys are selected for their mechanical or chemical properties to enhance the coating's performance. For more information, see our guide on the properties of alloys.

What Are the Advantages of Laser Cladding?

The following are the benefits of laser cladding:

- Precision and accuracy in depositing materials.

- Control over the deposited material’s composition and resulting microstructure.

- Enhanced surface properties such as wear resistance, corrosion resistance, and thermal performance.

- Reduced material waste and cost savings.

What Are the Disadvantages of Laser Cladding?

The following are some drawbacks to laser cladding:

- High initial equipment cost.

- Limited deposition rates compared to other processes.

- Thermal stresses and distortions in the substrate.

- Limited material compatibility, particularly with materials that have vastly different melting points or poor wetting characteristics.

- Complex setup and parameter optimization are required.

How Much Does a Laser Cladding Machine Cost?

The price of a laser cladding machine depends heavily on its size, features, and productivity. A large-scale machine may cost between $250,000 and $350,000, whereas a small-scale machine may cost around $100,000. There are hobby-grade or compact laser deposition units priced under $15,000, but they typically lack the power and automation features of industrial laser cladding systems.

How Long Does a Laser Cladding Machine Last?

A laser cladding machine's lifespan will depend on how the equipment is used and maintained. Most laser machines can last up to 15 years under proper usage. This will vary, however, depending on several factors such as the design and manufacture of the laser itself, the operating power that is used versus the rated power of the device, and the operating temperature of the laser.

Frequently Asked Questions About Laser Cladding

Is Laser Cladding a Type of Additive Manufacturing?

Yes, laser cladding is considered a directed energy deposition (DED) process within the family of additive manufacturing. It builds up material in layers, though it's more commonly used for coating, repair, or feature addition than full part creation.

Is Laser Cladding the Same as Laser Welding?

No, laser welding and laser cladding are not the same. A layer of material is deposited onto a substrate during laser cladding, whereas a laser beam is used during laser welding to fuse two or more workpieces together.

Can Laser Cladding Add Multiple Layers of Different Materials to a Substrate?

Yes, a substrate can receive multiple layers of different materials through laser cladding. It is possible to deposit multiple layers with different compositions and properties onto the substrate by adjusting the feed material and laser parameters.

Can Laser Cladding Add a New Layer of Material Onto a Substrate?

Yes, laser cladding is made specifically to cover a substrate with new layers of material. The main purpose is to improve the substrate's characteristics.

What Is the Difference Between Laser Cladding and Laser Cutting?

While laser cutting involves removing material to create a cut, laser cladding involves adding material to a substrate. Laser cutters slice through the material while laser cladding machines build up layers of new material.

Summary

This article presented laser cladding, explained it, and discussed the processes and different types. To learn more about laser cladding, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including sheet cutting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.