Reshoring is the process of moving manufacturing or engineering operations back to their domestic bases from previously established foreign sites. Over time, many companies sent production or service operations to foreign locations to take advantage of lower labor and production costs. However, offshore labor costs are rising, and technology is reducing domestic production costs. Reshoring jobs has many long-term benefits for the industry and the home country.

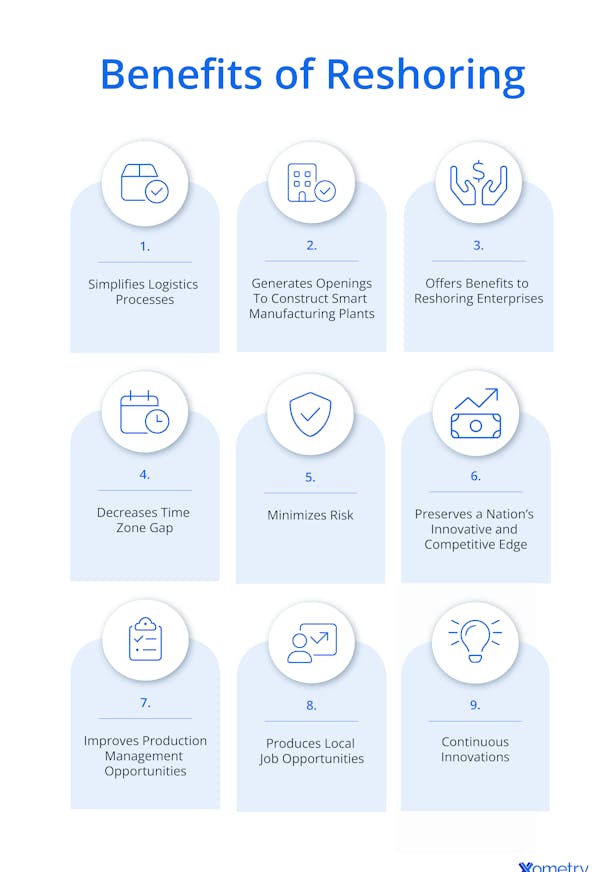

Listed below are nine benefits of reshoring production.

1. Simplifies Logistics Processes

Logistics involves many potential points of failure, and reshoring reduces the transportation and coordination needed to deliver finished products to the domestic US market.

Logistical issues can also complicate the resolution of disputes over defective products. If defective parts are shipped from a foreign production location, it will be a much bigger challenge to detect, reject, and replace the bad parts in a timely fashion. This scenario creates unhappy customers whose orders cannot be fulfilled as promised.

2. Generates Openings to Construct Smart Manufacturing Plants

When a company decides to reshore a manufacturing operation, there may be no suitable production facility available. The factories that produced those parts before the original offshoring may have been shut down long ago, or even torn down. This apparent downside to reshoring can have big long-term benefits: it can spur the construction of more technically up-to-date “smart” manufacturing plants domestically.

Smart plants are part of what is often referred to as Industry 4.0, or the fourth industrial revolution. They take advantage of highly automated and interconnected plant-wide sensor arrays and data analysis based on machine learning and artificial intelligence to monitor and respond to everything that happens in the factory. After the initial high capital investment, such facilities can produce higher-quality goods and, in some cases, achieve competitive costs compared to foreign plants.

3. Offers Benefits to Reshoring Enterprises

Reshoring can also benefit third-party companies that specialize in assisting manufacturers with bringing production back to the US. Work can be provided to reshoring consulting companies that can assist companies in assessing relevant cost and risk factors of these decisions and advise retailers, brands, and contract manufacturers. Researchers tracking reshoring and nearshoring activities argue that a move towards reshoring is indicative of and beneficial for a move towards reimagining and modernizing the supply chain.

4. Decreases Time Zone Gap

Decreasing the time zone gap will boost communication between different points in the supply chain. Increasing communication resolves problems faster and more effectively by getting eyes on the process quickly, thus enabling quicker decision-making. A decreased time zone gap also allows for solving problems together in person, enabling better collaboration and a higher chance of a better outcome.

5. Minimizes Risk

Reshoring reduces supply chain complexity, shortening lead times and lowering the risks of importing goods.

6. Preserves a Nation’s Innovative and Competitive Edge

Reshoring production facilities also means reshoring the manufacturing and product expertise that accompanied the product's original departure from US soil. Sometimes the expertise has to be rebuilt, sometimes it just has to be retrieved by restoring lost manufacturing employment opportunities. A vibrant and growing domestic manufacturing sector will produce a stable and skilled workforce and enhance national security. It will keep American innovation leaping ahead and bolster America’s ability to outcompete other global players.

7. Improves Production Management Opportunities

Companies that reshore gain opportunities for better production management, as their operations are all local. For example, reshoring the fabrication of a finished product's basic and intermediate components makes the final product's supply chain more accessible and controllable.

8. Produces Local Job Opportunities

According to Reshoring Initiative® data, about 350,000 jobs were announced in 2022, the highest level since tracking began in 2010. These jobs represent around 3% growth in the US manufacturing labor force, with many not requiring a college education. This, therefore, creates more economic opportunities.

9. Continuous Innovations

Reshoring can support innovation opportunities for American industry by strengthening local supply chains and encouraging investment in advanced manufacturing, which benefits consumers through greater competition.

What Are the Reasons Why Companies Prefer Reshoring Over Other Outsourcing Models?

There are a number of reasons why a company may choose to reshore operations rather than set up offshore outsourcing contracts. Here are six of the most common reasons why businesses choose reshoring over outsourcing:

1. Eagerness to Enhance Domestic Economy

Reshoring creates more highly skilled jobs that can grow and enhance the domestic economy. In the US, manufacturing accounts for about 12% of GDP, nearly 60% of exports, 70% of private-sector R&D spending, and around 20% of capital investment. Analysts estimate that restoring competitiveness in key manufacturing industries could significantly boost GDP, though projections such as 15% growth by 2030 are speculative. A strong manufacturing economy can create advancement and employment opportunities. Reshoring operations can heavily contribute to building a strong manufacturing economy.

2. Shortens Delivery Time

The problem with offshoring has always been delivery times. For example, standard air freight from China to the US typically takes 5-10 days, depending on routing and customs clearance. Reshoring operations will cut down on these delivery times as there is a much shorter distance to cover.

3. Enhances Supply Chain Control

Reshoring gives companies greater control over supply chains by making coordinating raw materials and final products easier within one domestic system. This is because the entire chain is more accessible. Additionally, domestic transporters such as trucks and trains do not run the same risks as shipping containers crossing the ocean.

4. Stabilizes Workforce Expenses

Labor has traditionally been less expensive abroad. Recent figures show significant wage inflation in offshore manufacturing countries. In China, average manufacturing wages have increased more than tenfold since the early 2000s, narrowing the labor cost gap with developed economies. Data published by the PEW Research Center shows that labor costs in the US have remained relatively consistent for the last decade, with little fluctuation. The same is true of Canada. Hence, reshoring operations back to the US can help stabilize workforce expenses.

5. Enhances Availability of Skilled Labor

Once reshored, companies can benefit from a highly skilled pool of labor. This can often be a reason companies decide to reshore, as skilled labor isn't always available offshore. One study found that more than 70% of companies surveyed cited better access to skilled labor as a reason for reshoring.

6. Meets Legal Standards

Offshoring can become complex as products made offshore may be made to different regulatory standards than those made domestically. This can create challenges around the safety of products that are imported for sale. Reshoring helps companies align with domestic legal and regulatory standards since production must comply with local labor, safety, and environmental laws. However, companies may still need to meet specific certification or compliance requirements before selling domestically.

In one of my projects, long time zone gaps and limited on-site access slowed decision-making. Reshoring reduces these frictions: communication is more direct and supplier verification becomes routine.

What Are the Disadvantages of Reshoring?

Not all of the effects of reshoring are positive. Listed below are its disadvantages:

- High Overhead: The cost of labor in the US is usually higher than the cost of labor abroad, which is why a lot of industry was transferred overseas in the first place. This high labor cost can make US-made products less price-competitive than those produced abroad. However, investments in automation and advanced manufacturing can offset part of the labor cost disadvantage.

- Commitment of Resources: Successful reshoring takes time, attention, and capital investment. The initial phase of reshoring can lead to temporary delays in production, impacting the end consumer and delivery times, and thus having cost implications. A commitment of resources would be required to mitigate these potential teething problems to ensure adequate planning and risk assessment to maintain continuity and minimize disruptions.

- Recertification: Given the varying standards required in different countries, different standards may apply to a product produced domestically compared to one imported. For example, a domestic factory in the US may not be allowed to foul the water and air to the same degree as factories abroad. To reshore operations and comply with US standards, companies may need additional certification or testing, and in some cases, product modifications to meet regulatory requirements.

- Availability of Resources: Reshoring operations will require the employment of domestic resources, which can take a long time and be expensive. The recruitment and hiring process can take a long time, and once hired, the onboarding process can take a few weeks. Limited availability of skilled labor and other immediate resources can disadvantage reshoring, as recruitment, training, and onboarding take time and add costs.

How Does Reshoring Work?

Reshoring consists of moving a manufacturing activity back from an overseas location to a domestic location where it had previously been performed. Typically, new, modernized domestic production facilities are opened to replace the volume that was previously shipped back to the US. The foreign plant may or may not be forced to close, depending on the availability of other manufacturing projects.

How Does Reshoring Impact Domestic Employment and Job Opportunities?

Reshoring will reduce domestic unemployment and expand job opportunities. In the plastics product manufacturing industry, estimates suggest that for every 100 direct jobs, roughly 250-280 additional jobs may be supported indirectly, through suppliers and induced economic activity. Reshoring these direct jobs creates more job opportunities for the domestic market, thus increasing local employment. This is because not only does someone need to fill that job, but other jobs must also be filled to support the new employee. For every job, reshored extra jobs may be created in leisure, retail, and travel industries as the newly employed have money to spend, and jobs may be created to support the activity at the newly reshored site, including in logistics and public services.

How Does Reshoring Address Concerns Related to Geopolitical Risks and Global Supply Chain Disruptions?

Reshoring addresses geopolitical concerns by moving the supply chain “in-house.” This means that if global trade is reduced due to the closure of transport links, then “reshored” supply chains are at a lower risk of disruption. Recently, global supply chains have been impacted by the invasion of Ukraine, the blockage of the Suez Canal by the container ship Ever Given, and the disruptions from the COVID-19 pandemic. It is possible that disruptions on this scale could occur again at major transport links, including the Suez Canal, Panama Canal, and the South China Sea. Reshoring supply chains reduces the risk of any major supply chain disruption.

How Does Reshoring Change the Overall Cost Structure for Businesses?

Reshoring will change a business's cost structure by altering logistics, labor, management, and facilities costs. The costs of labor, management, and facilities will rise, while the cost of logistics will be greatly reduced. This may not make reshoring an attractive option at present. However, reshoring can be considered an investment for the future of a business that will pay off in the long term. This long-term strategy relies on the expectation that wages in major offshore manufacturing countries will continue to rise, reducing the cost advantage of cheap labor abroad and making reshoring more competitive. Over time, this will erode any benefit that offshoring labor has.

How Does Reshoring Intersect With Advancements in Automation and Technology Adoption?

The adoption of new automated technologies tends to drive down the price of domestic product production by replacing expensive labor with machines that can produce high-quality, repeatable parts with little human intervention. The equipment needed to implement high levels of automation often represents a large capital investment. However, once modernized machinery, networks, and methods are online, they can rapidly produce high-quality goods, and in some cases achieve costs comparable to or lower than overseas production plus shipping. Advancements in Industry 4.0 technologies, such as AI and additive manufacturing, are crucial to making reshoring cost-effective and financially viable.

Can Reshoring Rapidly Adapt to the Latest Technology in the Market?

Yes, reshoring initiatives can rapidly adapt to the latest technologies. Technology can help deliver agility, such as quick Time to Insight (TII) for manufacturers to provide a detailed view of sustainability across supply chains and gain more accurate forecasting. According to an IFS study, 37% of respondents are prioritizing technology investment to solve supply chain management problems. New technology under the broader concept of Industry 4.0 supports the automation of many labor-intensive tasks. These technologies include agile and flexible software platforms, strong ERP solutions, and automation solutions like MES/MOM (Manufacturing Execution and Operations Management Systems) software.

What Is the List of Industries That Have Experienced Success From Reshoring Operations?

Industries that have experienced success from reshoring operations include:

- Transportation equipment manufacturing

- Electronics, with partial US assembly by companies such as Apple

- Consumer goods and footwear, with examples like New Balance

- Aerospace and defense

What Is the Impact of Reshoring on a Nation’s Trade Balance and Overall Economic Growth?

Reshoring can create domestic jobs and support economic growth. While this may help reduce trade deficits in some cases, the overall impact depends on industry scale, import substitution, and global trade dynamics.

What Role Does Government Policy Play in Encouraging or Supporting Reshoring Initiatives?

Data from the Reshoring Initiative® show that government incentives were a leading factor in the decision to reshore rather than invest in foreign countries for at least 1,594 companies between 2010 and 2021. For example, the life sciences manufacturer GRAM is investing $160 million in a project supported by $120 million in US government contracts to expand its domestic manufacturing capacity. Government policy, therefore, plays a major role in encouraging reshoring. Prominent measures include the CHIPS and Science Act, which directs more than $50 billion into US semiconductor manufacturing and research, as well as the Inflation Reduction Act and the Infrastructure Investment and Jobs Act, which provide large-scale support for clean energy, EV batteries, and advanced manufacturing. Alongside these incentives, tariff measures on imports have also reshaped sourcing decisions by raising the cost of relying on foreign suppliers. Together, incentives and tariffs form the two main policy levers driving current reshoring initiatives.

Does Reshoring Have the Same Benefits as Other Outsourcing Models?

There are a variety of outsourcing models available to improve company operations without hiring additional employees and cover skills not present in the current workforce, such as professional outsourcing, IT outsourcing, process-specific outsourcing, and many others. Advantages of these models include lower operating costs, reduced pressure on the current team, less office space required, and a wider talent pool. Reshoring can provide some similar advantages, such as improving efficiency and reducing coordination burdens, but it differs from outsourcing models that primarily focus on lowering costs and accessing global talent pools.

Frequently Asked Questions About the Benefits of Reshoring

Does Reshoring Have the Same Benefits As Nearshoring?

Yes, reshoring shares some benefits with nearshoring, but not all. Reshoring brings operations back to the domestic market, while nearshoring moves them to neighboring countries. Nearshoring can reduce logistics costs while offering lower labor expenses than in the US, making it a middle ground between offshoring and reshoring.

The benefits that reshoring and nearshoring share include reduced logistics costs, shorter lead times, increased supply chain control, and minimized risk from transport disruption. These advantages apply to varying degrees depending on the industry.

Does Reshoring Have the Same Benefits As Offshoring?

Yes, reshoring can now provide some of the same financial benefits as offshoring. Rising offshore labor costs and lower domestic production costs through technology have narrowed the gap. However, differences remain: reshoring improves access to skilled local labor and reduces logistics complexity, while offshoring may still lower direct labor costs in some regions.

Does Reshoring Have the Same Benefits As Onshoring?

Yes, reshoring and onshoring provide the same benefits since both keep production within the domestic market. The difference is that reshoring restores operations that once existed, while onshoring starts them from scratch, often requiring greater investment.

Summary

This article presented the benefits of reshoring, explained each of them, and discussed how each is a benefit. To learn more about reshoring, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.