Xometry Capabilities Navigator

From prototyping to production, our network of over 10,000 suppliers has the capacity for all of your manufacturing projects. Select a capability below to explore how Xometry can bring your big ideas to life. Explore all of our capabilities.

Machining and Turning

Custom Online CNC Machining Services

Thermoplastic Additive Manufacturing / 3D Printing

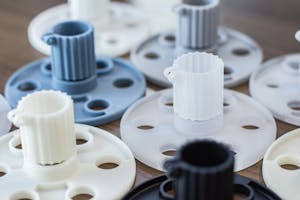

Fused Deposition Modeling (FDM) 3D Printing Service

HP Multi Jet Fusion (MJF) 3D Printing Service

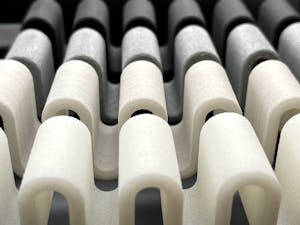

Selective Laser Sintering (SLS) 3D Printing Service

Resin Additive Manufacturing / 3D Printing

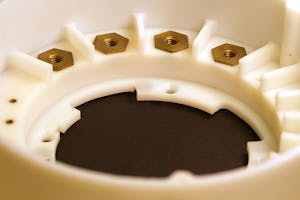

Stereolithography (SLA) 3D Printing Services

PolyJet 3D Printing Service

Carbon Digital Light Synthesis™ (DLS™) 3D Printing Service

Metal Additive Manufacturing / 3D Printing

Direct Metal Laser Sintering (DMLS) 3D Printing Service

Metal Binder Jetting 3D Printing Service

Sheet Metal and Tube Cutting and Bending Services

Sheet Metal Fabrication Services

Laser and Sheet Cutting Services

Tube Bending Services

Laser Tube Cutting Services

Plastic Molding, Casting, and Production

Custom Plastic Injection Molding Service

Urethane and Silicone Casting Services

Custom Plastic Extrusion Services

Metal Casting, Stamping, and Production

Metal Stamping Services

Metal Extrusion Services

Value-Added, Turnkey Solutions

Custom Online Weldment Services by Xometry