Manufacturing on Demand for the Medical Industry

Trusted by Over 86% of the Fortune 500 Medical Products and Equipment Companies

Turbocharge the Way You Make Custom Parts

Massive Network Capacity

Instantly access the production capacity of over 10,000 manufacturers with wide-ranging capabilities and certifications across 46 states and around the world. From your desktop. Strict NDA agreements with our network protect your privacy.

Instant Quoting Engine

Get DFM feedback, lead times, and pricing in a matter of clicks, not days. Xometry IQ℠ puts Data Science to work for you so you can easily choose the optimal price/lead time option for your project. Compatible with STEP, Mesh, Parasolid, and ACIS files.

Quality Assurance

We are certified to ISO 9001:2015, ISO 13485, IATF 16949:2016, and AS9100D. We are ITAR registered, and offer CoCs, material certifications, material and process lot traceability, full dimensional reports, inspection reports, and hardware certs. See more details about our Quality Assurance capabilities here.

Innovate Faster With Custom Manufacturing for the Medical Industry

Xometry works with leading medical device makers, wearable tech startups, suppliers, and research labs to accelerate rapid prototyping and dynamically scale manufacturing capacity. Over 86% of Fortune 500 medical products and equipment companies depend on our production capabilities such as an industrial-grade 3D printing service, high-tech CNC machining processes, and advanced medical injection molding for rapid prototyping, product testing, custom tooling, and custom design manufacturing.

Top Medical Device & Hardware Applications

- Ventilator parts

- Models for clinical training and surgical planning

- Highly variable, low-volume production runs with high-precision tolerances

- Custom tooling brackets and chassis for medical manufacturing

- Rapid prototyping of medical devices using additive manufacturing

- Rapid prototyping of medical devices using CNC machining

- Custom fixturing

- Personal protective equipment (PPE)

Trusted by Medical Engineers and Designers at Over 86% of the Fortune 500 Medical Products and Equipment Companies

- Medical device manufacturers

- Healthcare providers

- Life sciences

- Biotechnology corporations

- Pharmaceutical companies

- Diagnostics equipment manufacturers

- Surgical and medical instrument manufacturers

- Surgical appliance manufacturers and suppliers

- Hospital operators

Medical Manufacturing Capabilities

Custom Online CNC Machining Services

Medical Injection Molding Service

Custom Online 3D Printing Service

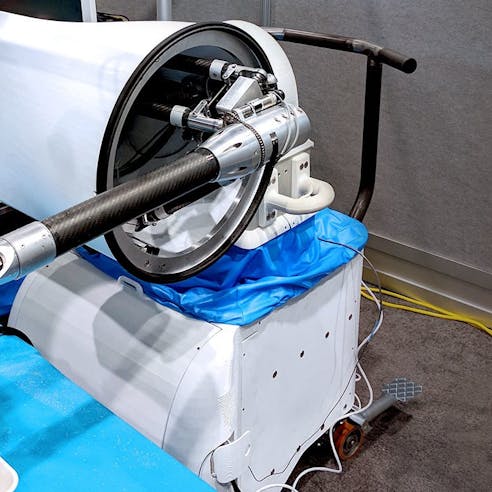

Case Study: Medical Robot Built by Galen Robotics Prototyping With Xometry

Medical Manufacturing Services

Injection Molding

Sheet Metal

3D Printing

Urethane Casting

Medical Post-Processing Capabilities

- Anodizing

- Passivization

- Electroplating

- Powder Coating

- Insert Installation

- Heat Treatment