The concept of 3D-printed foods is as intriguing as it is incredibly innovative. Blending advanced technology with culinary art, chefs and restaurateurs everywhere are excited at the prospects that 3D-printed food has to offer. Food made with a 3D printer tastes just like regular food because it’s made with regular, edible ingredients. The difference with this type of food is not in the taste, but in its texture and how it looks. Chefs can let their creativity shine and make unique and visually stunning foods, which will thrill customers by engaging their senses and elevating the overall dining experience.

Note: While here at Xometry we don’t yet offer 3D-printed food services, we did help to make parts for the first-ever commercial 3D chocolate printer, created by entrepreneur Ellie Weinstein. All the details on this venture can be found in the below video:

We are also closely monitoring the progress in this interesting space and will keep you updated on any developments. In the meantime, here’s a look at the history of 3D-printed foods, how they are made, and their pros and cons.

A Brief History

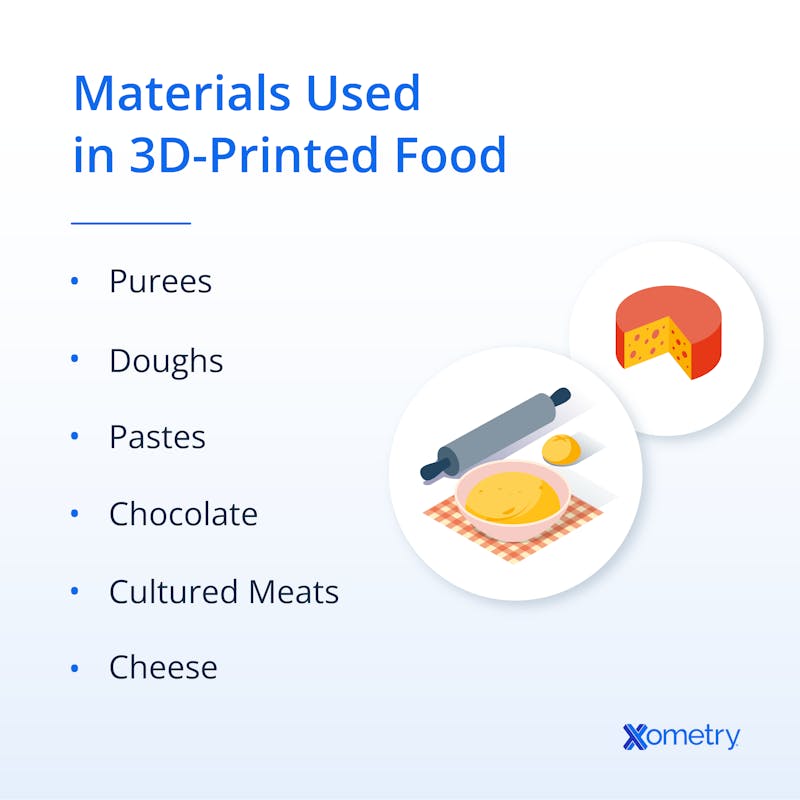

The first foods were 3D printed in 2006 by a team of researchers at Cornell University’s Mechanical and Aerospace Engineering Department. The foods in question were chocolate, cookie dough, and cheese. The team developed an open-source, multi-material 3D printer called the Fab@Home that used precise extrusion syringes. Since then, a whole host of ingredients have been tested in various forms. These include purees (mashed potatoes and beans, hummus, applesauce), pastes (butter, icing, tomato, bean), and cultured meats (vegan meats, fat cells).

3D-Printed Foods Today

Beyond the ability to make foods with difficult shapes and intricate details that would be a major hassle to make by hand, this technology can also make foods that cater to personal nutrition needs, whether it’s food allergies, intolerances, or preferences. It can make dishes for those on vegan, gluten-free, or dairy-free diets, and help them make healthier choices when dining out and options for particular diets are limited. Foods can be personalized with names or other customizations and even make a bespoke consistency for ultimate customer satisfaction. This can prove particularly useful for children who are sensitive to certain food textures and could help broaden their notoriously limited food palate.

The 3D-printed food method is quick, reduces prep time, makes efficient use of ingredients, and minimizes food waste (and, in turn, food scarcity and global food shortages) as it only uses the exact amounts needed. In addition, it keeps costs down for businesses and helps the fight toward sustainability. Another way it can help a food business is by producing the exact same product every single time—top chefs have been known to toss a plate of perfectly edible food in the trash because it doesn’t look as uniform as the others.

Because it’s not yet mainstream, public perception and acceptance of 3D-printed foods isn’t as high as you’d think. People are weary of the role of technology in food prep and may question the food’s authenticity, quality, or the proper sanitization of the machinery. There’s also not a large array of ingredients compatible with 3D printers (yet!), and its current speed and scale might not meet the demands of busy restaurants or food services. In addition, the initial investment in one of these printers is quite high (and let’s not forget about maintenance) so smaller businesses might struggle to jump on the bandwagon. Workers will also need adequate training on how to use the machines. There are also the issues of hygiene, safety, and regulation, which haven’t been ironed out yet.

How 3D-Printed Food Is Made

3D printing food works in the same way as ordinary additive manufacturing, particularly fused deposition modeling: by building the product—in this case, the food—one layer at a time. But before that, a digital CAD (computer-aided design) file must be made. The file has the exact instructions, including consistency, shape, size, and any other details that the printer will follow to make the food. The ingredients have to be blended or processed into a compatible consistency so that they can be extruded onto the build platform through the printer’s nozzle, just like filament would. They’re then loaded into the printer, and the CAD file is transferred to the printer so that it can start printing.

Just before technicians hit “print,” they’ll make sure the settings (like parameters, temperature, and extrusion speed) are where they should be. There’s not much manual effort needed once the machine starts printing, other than monitoring. Depending on what you’re making, there might be some post-processing required. For instance, cookie dough, which is extruded as a paste, will need baking after printing. Since they’re extruded in liquid form, chocolate and cheese need to solidify before being taken off the plate. Thankfully, they both tend to cool rather quickly. Other items might need some finishing touches, like glazing or garnishing.

How Xometry Can Help

While we don’t yet offer 3D food services, we do make a host of 3D-printed food-safe products. We also have a wide range of other manufacturing capabilities for all of your prototyping and production needs. Learn more about our custom online 3D printing service and get your instant quote today.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.