What is Stereolithography, and Why Should You Use it?

Stereolithography, otherwise known as SLA, is a powerful 3D printing technology that produces highly accurate, high-resolution parts perfect for product development, rapid prototyping, concept models, and injection mold design verification. This additive manufacturing process focuses an ultraviolet (UV) light on a vat of photopolymer resin, producing a higher resolution print when compared to many other 3D printing technologies. SLA allows customers to print parts with fine details and smooth surface finishes, and it’s a fantastic manufacturing solution when you are looking to print parts with crisp, clean features and tight tolerances. In addition, SLA prints do not suffer from fine detail limitations inherent in other 3D printing processes like Fusion Deposition Modeling.

What is Ceramic-Filled Resin?

SLA photopolymer resins are most commonly formulated to behave like known plastics, from flexible polypropylene to a stiff polycarbonate. In these cases, the formulations are adapted to mimic different levels of flexibility and elongation before breaking. Ceramic-filled resins take a different approach, where they are not designed to mimic plastic, but instead very stiff materials like porcelain. Ceramic-filled resins are liquid photopolymer suspensions with a high percentage of ceramic spheres. Looking more like a slurry compared to other photopolymers, a ceramic-filled resin will harden under UV light and the shape remains incredibly stiff and stable due to the embedded ceramic.

Xometry offers 2 ceramic-filled materials for 3D printing; SLA Somos® PerFORM and Accura® Bluestone™. Both materials will create a highly stiff structure with a smooth stone surface finish when 3D printed. This process, combined with the use of ceramic-filled materials, produces parts that are extremely CAD accurate when compared to most additive processes. Ceramic-filled SLA parts are best used in devices and prototypes that require thermal stability over a range of temperatures. In addition, ceramic-filled SLA materials are typically useful in others applications including mounted fixtures and optical devices where high accuracy and stability are paramount.

If you are looking for a material with the highest level of stiffness, along with solid heat and abrasion resistance and excellent chemical resistance, consider using Accura® Bluestone™. On the other hand, if you are looking for a material that is faster to build, easier to post-process clean, possesses superior sidewall quality, and provides unmatched detail resolution, you may want to consider using Somos® PerFORM material. It is the ideal material for creating strong, stiff parts with excellent high heat resistance, including wind tunnel models for aerospace and automotive applications, as well as rapid tooling for an injection molding project

FREE SLA 3D Printing Design Guide

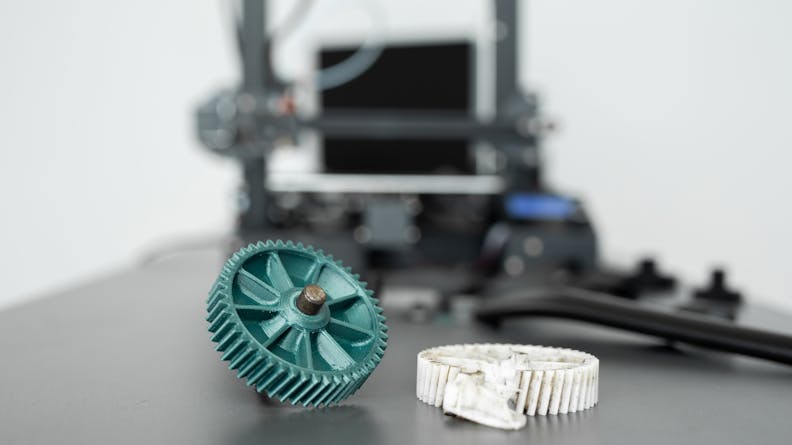

A picture of 2 plastic parts, one intact and one that is broken.

Image Credit: Freepik.com/Seguir

If you want to print a custom part with fine, delicate features, you may want to avoid using ceramic-filled SLA materials. Ceramic-filled materials have practically no flexibility, unlike many SLA resins meant to mimic thermoplastics. Their lack of flexibility can make it very fragile. This is a very important distinction, as this highly stiff material will snap rather than bend if you expose it to pressure. It is also important to remember that materials like Somos® PerFORM and Accura® Bluestone™ are not pure ceramic material; they are made from a resin slurry mixed with ceramic materials. Unfortunately, this means that it can’t withstand heat as well as a pure ceramic material.

In Summary

Ceramic-filled SLA material like Somos® PerFORM and Accura® Bluestone™ may not be ideal for every project. Still, if you are looking for an accurate printing process with the ability to produce high-resolution parts with excellent heat and chemical resistance, ceramic-filled materials may be the right match for your next project. We encourage you to head over to Xometry Instant Quoting Engine! There, you will get instant pricing for ceramic-filled SLA parts with lead times that start at 3 days.