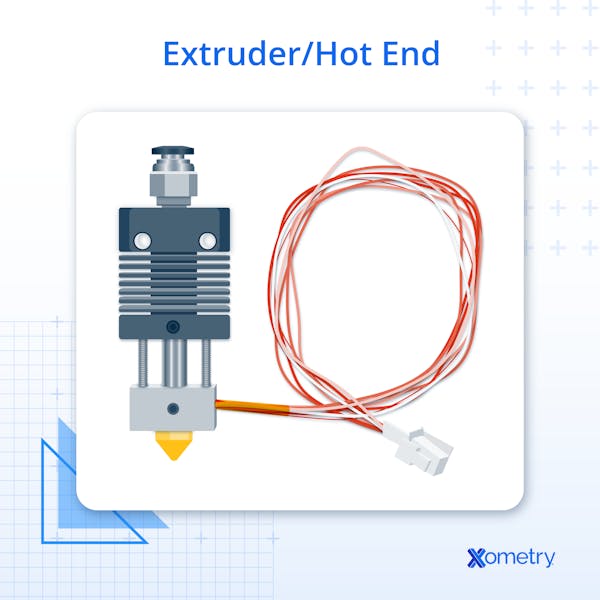

Hotends are the most crucial component of an FDM (fused deposition modeling) 3D printer, because they melt the plastic filament before it is applied, layer by layer, to build up a 3D part. The hotend primarily consists of a nozzle, a heat block, a heat break, and a heat sink. These components work together to melt the plastic as quickly as possible while simultaneously confining the heat to the heat block. Hotends are available both as all-metal assemblies and as metal-plastic hybrids in which a PTFE tube is used inside the hotend but does not form part of the nozzle. A high-quality hotend ensures consistent temperature control. Precise temperature control results in consistently good prints with minimal blockages inside the nozzle. Figure 1 below shows a basic hotend assembly:

This article will describe in detail what hotends are, how they work, and how to choose the best one, as well as provide troubleshooting and maintenance tips.

What Are Hotends?

A 3D printer hotend is a component used in FDM (fused deposition modeling) 3D printers. It is designed to melt the plastic filament that is pushed into it by an extruder. The hotend consists of a chamber that is heated by a heating element, which is under closed-loop heating control using a thermistor for temperature feedback. The bottom of the hotend has a removable nozzle that deposits the material onto the build plate of the 3D printer. Hotends are almost exclusively used in printing plastics, which have low melting temperatures and are also able to cool more quickly.

How Do Hotends Work in 3D Printing?

A 3D printer hotend forms part of the extruder assembly. The plastic filament enters the top of the extruder, where it is engaged by a toothed wheel. This toothed wheel is spring-loaded so that it can provide constant contact pressure on the filament. The toothed wheel is driven by a stepper motor whose speed is determined by the specific printer settings chosen by the user.

The toothed wheel then pushes the plastic down into the hotend, which consists of a heating cartridge, a heat block, a heat sink, a filament guide, a thermistor, a nozzle, a cooling fan, and a filament guide. The heating cartridge is attached to a solid block of metal that surrounds the filament guide. This configuration is located just upstream of the nozzle. It is separated from the rest of the hotend assembly by a heat break to prevent heat from traveling back upstream through the hotend assembly. A thermistor is also situated inside the metal block in order to provide feedback for temperature control since each plastic requires a different temperature in order to melt.

As plastic is forced into the heating zone by the extruder, it begins to melt and is forced through either a brass or steel nozzle with an opening of anywhere from 0.1-1.4 mm in diameter. The plastic is forced through the nozzle because the extruder is continuously pushing more plastic into the filament guide. The hotend typically has a heat sink attached to it. This ensures that heat from the heating cartridge does not travel back upstream from the heated chamber causing the material to melt prematurely, a phenomenon called “heat creep.” An additional fan may be attached to blow air over the heat sink. The hotend is moved around the x, y, and z axes of the printer bed by 3 additional stepper motors.

For more information, see our guide on Heat Creep.

What Are the Different Types of Hotends?

In general, all 3D printer hotends operate on the same fundamental principle, but some are better designed to prevent heat creep than others and can make use of different materials that require higher melting temperatures. Listed below are some common hotend types:

- Plastic-Lined: Plastic-lined hotends are found on most low-cost or entry-level 3D printer extruders and typically have a PTFE or PEEK tube inside the hotend. This insert serves two functions. First, it reduces the friction inside the hotend and prevents the filament from sticking to the nozzle walls. Second, it helps reduce heat transfer from the heater block due to the lower thermal conductivity of the plastic liner. This helps prevent heat creep.

- All-Metal: All-metal hotends are designed to print plastics with high melting temperatures, such as polycarbonate and nylon. As a result, they do not have PTFE liners, which begin to soften at the higher printing temperatures required for higher-melting-point materials. Since they do not have plastic liners to block heat transfer from the nozzle, all-metal hotends make use of heat breaks and materials with low thermal transfer coefficients to eliminate heat creep and use low-friction metals with polished surfaces to reduce friction.

How to Choose the Right Hotend for Your 3D Printer

Choosing the right hotend for your application is relatively easy. Listed below are some points to consider before making a decision:

- Materials: When choosing a hotend, it is important that you have a clear idea of what materials you will be printing. For standard materials like PLA, PETG, or ABS, a standard PTFE-lined hotend will suffice, as the melting temperatures are not too high. However, for higher melting-point plastics like polycarbonate or nylon, an all-metal hot end is preferable.

- Printer Compatibility: When swapping out the stock hot end for an improved one it is important to make sure it is compatible with existing printers. While the vast majority of hotends have the same general design, it is important to make sure that the hotend is mechanically and electrically compatible with your printer. In terms of mechanical compatibility, the hotend needs to mount onto the existing extruder assembly. To maintain electrical compatibility, the heating cartridge and thermistor must be compatible with the printer control board.

- Nozzle Type: Nozzles are supplied in brass, hardened steel, and ruby-tipped steel. Some printing filament materials may be extremely abrasive — especially metal powder or carbon-filled plastics. In this case, a hardened steel nozzle or a ruby-tipped nozzle is required for optimal results. When printing materials that don't have special-purpose fiber or particle fillers, like nylon, ABS, or PLA, then a standard brass nozzle will suffice. Nozzles have different aperture sizes, with smaller apertures providing finer print detail at the expense of speed and larger apertures providing lower quality, but higher print speeds.

What Are the Advantages of Hotends for 3D Printing?

Hotends are critical for any functioning FDM-style 3D printer. Listed below are some advantages of a well-designed hotend:

- Increased Printing Speed: A well-designed hotend is optimized to have reduced weight while still effectively heating the plastic and preventing heat creep. A lighter weight means that higher printing speeds can be achieved, as there is less mass to move around the print bed. Faster heating also allows for higher extrusion rates, which are critical for high-speed printing.

- Reduced Blockages: A number of factors, such as heat creep, poor temperature regulation, and poor temperature distribution, can cause blockages inside a hotend. A well-designed hotend will eliminate these issues by using materials with low thermal conductivity to prevent heat creep. You can also use high-quality heating elements and thermistors to improve temperature regulation and design the heating block to effectively transfer heat into the plastic in a consistent manner.

What Are the Disadvantages of Hotends for 3D Printing?

To achieve optimal results with FDM 3D printing machines, a good-quality hotend is essential. Listed below are some disadvantages of a poorly designed hotend:

- Poor Print Quality: A low-quality hot end may have poor temperature control. When the temperature is not controlled within a narrow, consistent range, the filament material will not exit the nozzle with the consistent properties generated by tight temperature control. This can create defects in the print, increase warping, and reduce interlayer bonding.

- Nozzle & Hotend Blockages: A poor-quality hotend can result in more blockages inside the hotend or nozzle and ultimately can cause print failures. This can be due to insufficient thermal isolation causing heat creep; low-quality machining inside the hotend resulting in a rough nozzle inner surface which increases the chances of the filament sticking; and finally, poor temperature regulation.

To prevent these issues, it may be necessary to upgrade the entire hotend. Alternatively, a poorly maintained hotend can also cause blockages. Regular maintenance and cleaning can help to reduce print failures.

How Do You Maintain a Hotend to Ensure Optimal Performance?

Regular maintenance is critical for optimal hotend performance. Listed below are some common maintenance activities for the maintainable components in a hotend:

- Nozzle: The nozzle must be cleaned regularly — both the outer surfaces and the nozzle aperture. This should be done while the nozzle is hot. The aperture size should also be checked as it can enlarge over time due to wear.

- Heating Block: The heating block houses the heating cartridge and the thermistor. It can get coated with plastic over time and must be regularly cleaned. Most heater blocks have a silicone cover to shield the user from burns as well as to optimize the heat transfer into the filament material. Make sure this cover is undamaged and clean.

- Thermistor: A faulty thermistor can cause inconsistent temperatures in the hotend. It can also completely fail if the cable is damaged or worn. Check the cable condition regularly. If possible, remove the sensor and place it in a cup of ice water (with unmelted ice) or boiling water to check if the temperature reading is accurate.

- Heating Cartridge: Over time, the heating cartridge can fail due to a faulty connection. If this happens the print will fail. Regularly inspect the cable to make sure that it is not damaged or worn out. Replace if required.

- Heat Break or Tube: For all-metal hotends, the heat break is often made from a material with low thermal conductivity and does not need to be replaced. However, some printers have PTFE tubes inside the hotend that can wear or degrade over time. These must be replaced if there is an increased occurrence of blockages. The heat break has a thin cutout/slot to reduce the potential area for heat to transfer through. Make sure this gap is clean, with no plastic debris or dust in it, as this can cause heat creep.

- Heat Sink: Make sure the gaps between the heat sink fins are clean of dust or debris, as this can reduce the performance of the heat sink.

How Can You Troubleshoot Clogs and Jams Hotend Issues?

Clogs and jams can be caused by a number of hotend issues. For example, the heater cartridge may not be getting hot enough to melt the plastic, or a faulty temperature sensor could be causing the wrong temperature to be communicated to the control system.

Heat creep can cause the plastic to melt too early, causing a jam.

Finally, the nozzle could be blocked with debris. It makes sense to first check the easiest potential cause, i.e. the nozzle, before disassembling the extruder assembly for a more thorough check.

What Are the Components of a Hotend?

Most hotends have the same general design, the plastic is fed to the hotend by an extruder. Listed below are the main components of a hot end:

- Nozzle: Nozzles can have aperture sizes anywhere from 0.1 to 1.4 mm in diameter. They can be made from brass, hardened steel, or ruby-tipped steel. Brass nozzles are used for nonabrasive materials without any fillers, such as PLA, PETG, and ABS. Hardened steel and ruby-tipped nozzles are used for more abrasive materials, such as metal or carbon fiber-filled filaments. Nozzles can be easily replaced or swapped out and tend to become blocked if not properly maintained.

- Heat Block: The heat block contains the heater cartridge as well as the temperature sensor. It provides even heating to the filament so that it melts just before it exits the nozzle. The nozzle and heat break both screws into the heat block. The heat block does not need to be replaced during the life of the hotend, but it can get dirty, which will reduce its effectiveness. For that reason, regular cleaning is required.

- Heat Break: The heat break is designed to limit heat transfer from the heat block to areas further upstream in the hotend. The heat break is typically made from a material with low thermal conductivity. It also has a reduced diameter that also helps reduce heat transfer. The heat break is not a maintainable item, but it can wear out if exposed to a highly abrasive filament.

- Heat Sink: The heat sink helps transfer any heat that has moved past the heat break to the surrounding air, via either passive or active cooling. For an actively cooled heat sink, a fan is used to increase the heat transfer rate from the heat sink fins to the surrounding atmosphere. The heat sink can get dusty, which will reduce its capacity to effectively transfer heat from the hot end. For more information, see our guide on What is a Heat Sink?

- Filament Guide: The filament guide is either a smoothly machined tube (in the case of an all-metal hotend) or a PTFE or PEEK tube (for standard hotends). The filament guide must have a low coefficient of friction as well as low thermal conductivity. PTFE or PEEK tubes need to be replaced as they wear out/degrade over time.

What Are Some Advanced Techniques for Optimizing Hotend Performance?

Several techniques for maximizing the performance of a hotend are listed below:

- Calibrate PID Control Settings: The PID (proportional integral derivative) control settings can either be automatically adjusted by the printer controller, or you can manually access the firmware. Adjust these values to optimize the temperature control loop for optimal results.

- Implement Active Cooling: Most hotends have a passive heat sink which dumps heat from the hotend into the surrounding air. However, if you want to print at higher temperatures and speeds, then this method of heat removal may not be sufficient. A heat sink's thermal dissipation can be enhanced with an active cooling setup. For example, a fan can be attached to the heat sink to blow cool air over the fins. A liquid-cooled system can also be used to maximize the heat transfer rate.

What Role Does Temperature Control Play in Hotend Performance?

The primary function of a hotend is to provide plastic melted to the right temperature to the nozzle for deposition onto the 3D print. Temperature control plays a critical role in fulfilling that function. The entire hot end is designed to add enough heat into the filament quickly enough to provide a consistent supply of plastic during printing. A hotend must also prevent excess heat from traveling upstream through the filament feeder assembly, where premature softening or melting can melt or break the filament and jam the machine. A quality hotend can effectively control the temperature and keep heat where it is required by employing effective heat breaks and heat sinks. Active cooling on the heat sink can help prevent heat creep.

For more information, see our guide on Ways to Avoid Heat Creep.

What Factors Should You Consider When Shopping for the Best HotEnds for Your 3D Printer?

When shopping for a new 3D printer hotend, there are a number of things to consider. The most important factors are listed below:

- Material Compatibility: The material that you plan on printing will determine which hot end is best suited for your application. For printing with standard materials like PLA, ABS, and PETG, a hot end with a PTFE insert is ideal. If you plan on printing high-temperature materials such as polycarbonate, then an all-metal hot end is needed.

- Printer Compatibility: Not all hotends are interchangeable. You need to make sure that the hotend you choose is compatible with your 3D printer. Both mechanical and electrical compatibility must be checked.

- Nozzle Compatibility: Some filaments, such as carbon-filled nylon, are extremely abrasive and will destroy a standard brass nozzle. If you plan on using these abrasive materials, then a hardened steel or ruby-tipped nozzle is the best. In addition, it is important that the nozzles used on the hotend have a standard thread size (e.g. M6), as non-standard nozzles can be expensive and difficult to source.

- Heat Containment: The best quality hotends are able to keep heat contained near the nozzle to prevent heat creep from causing blockages during printing. This is especially important if you are printing with high-temperature materials.

- Durability: Hotends made from quality materials will last much longer than cheaper alternatives. It is better to spend a bit more upfront to ensure your hotend will last the life of the printer.

Do Hotends Need Cleaning After Use?

Yes, cleaning the hotend after each print is the best way to ensure that it performs optimally on the next print. It is not necessary to completely disassemble the hotend after each print. Instead, cleaning the nozzle and making sure there is no debris or dust on the hotend is good enough. However, performing periodic maintenance on the entire unit can help prolong the life of your hotend.

Is the Hotend the Most Vital Part of a 3D Printer?

Yes. Without the hotend, a 3D printer will not be able to melt the plastic in order to deposit it onto the print bed. However, hotends are only important for FDM-style 3D printers.

Summary

This article presented hotends, explained what they are, and discussed the different types and how they work. To learn more about hotends, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.