3D printing is a method of making 3-dimensional objects by additive means based on digital models. The process of creating these 3D objects is called "printing." The term "3D printer" refers to the device which creates these objects. 3D printers are usually stand-alone devices that can be fed digital data and output physical objects. They find use in many fields and industries, including art, design, and engineering.

3D printers can be used to make anything from toys to business supplies to rocket engines. You can create a wide variety of items at home with 3D printers that are difficult to obtain in stores. However, the 3D printer market is a competitive one. Also, the price can vary depending on the model, brand, and features. To help you choose a 3D printer with confidence, this article will cover 10 factors to take into account.

1. Look Up 3D Printer Categories

There are many styles of 3D printers available, and each has its advantages and disadvantages. Learn the differences between each before making a decision. There are several options to choose from including: Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Digital Light Processing (DLP), Stereolithography (SLA), and Binder Jetting. SLA printers are faster than most others and produce the highest quality parts of all 3D printing technologies. DLP printers are faster still and they also produce detailed parts. However, they are not as good as SLA printers at creating small details.

2. Think About Purchasing One or Building One

If you’re going to build your 3D printer, you must have the right tools. These tools will include: a drill press, clamps, and vise grips as well as lots of screws, nuts, and bolts. You’ll also need to know how to use these tools so that when something breaks or falls apart (which is bound to happen), it won't be too hard for you to fix. If buying a premade one is more appealing to you, then go ahead and make a purchase. There are several price options available, so you’re sure to find one that is within your budget.

3. Check the Price

Pricing varies depending on the manufacturer, but it's important to compare prices. To get a good deal on a 3D printer, look for those that contain high-quality features for a reasonable cost. Price is not the only consideration — you want to balance cost against performance, build quality, and features. When looking at potential purchases, cross-reference their specs against competitors' products on websites such as Amazon and eBay. Visiting the stores where these products are sold directly may be even better since you can examine everything for yourself and talk to knowledgeable experts.

4. Analyze the Printing Materials Used

The type of filament determines your printer’s resolution and the quality of the finished product. There are a variety of printing materials out there, including: PLA, ABS, PET, and PETG. Knowing how these materials fare during 3D printing will help you choose which best suits your needs. For example, PLA can easily be printed without support structures, but it doesn't hold up well over time or multiple uses. If you opt for ABS, on the other hand, you’ll get better surface finishes and harder parts, but the printing plate may need more preparation beforehand. Additionally, check whether your preferred materials are easily accessible.

5. Verify the Safety Concerns

Make sure a 3D printer is safe for use before purchasing it. It is important to understand the risks associated with 3D printing as well as how to avoid mishaps. Common safety concerns include the following:

- Ensure that the people who use the printer have the skills necessary to operate it. Correct knowledge and skills will prevent injuries if something goes wrong.

- If you have children around, opt for a more child-friendly style. Some models do not require any harmful chemicals while others demand significant safety protocols and good ventilation. Moreover, always adhere to the instructions in the manufacturer's manual.

6. Verify the Level of Excellence

Check reviews from customers. It is also worth checking if the 3D printer meets industry standards and whether the company has quality checks in place. Additionally, find out how much time it takes the printer to print a model and compare that to other printers’ speeds. This information will help you determine if this model is worth your hard-earned money.

7. Possessing A 3D Model

A 3D model is essentially the blueprint for the object you wish to print. You can either create your own model or use a pre-made one from a library. If you're willing to spend the time learning how to use modeling software and making sure everything looks right, you may want to buy a CAD (computer-aided design) or other 3D design programs. If you choose to purchase a pre-made file, be sure it includes the dimensions.

8. Acquire STL files

The STL file format is the most common file type for 3D printing. It saves your 3D designs in a simple text format that is easy to modify. That text then gets uploaded to the printer and printed one layer at a time. You can find STL files online from retailers like Amazon. If you are looking for something specific, check Thingiverse. Thingiverse is an online repository where users post their models (and make them available to others) so they can share their skills.

9. Acquire Slicing Software

The slicer is a computer program that converts 3D models into layers and generates toolpaths. The toolpaths are instructions for the printer to follow in order to end up with a complete 3D part. The slicer software will generate G-code, which is the language that tells your printer how to move along its X, Y, and Z axes as it prints each layer of your design. Check which slicing software will work best with your preferred printer.

10. Find a Group of Brand Owners by Searching Online

You can also search online for 3D printer owners groups. The members will have gone through many of the same situations as you and may have answers to your questions and concerns. Their advice can make your decision easier.

What is a 3D Printer?

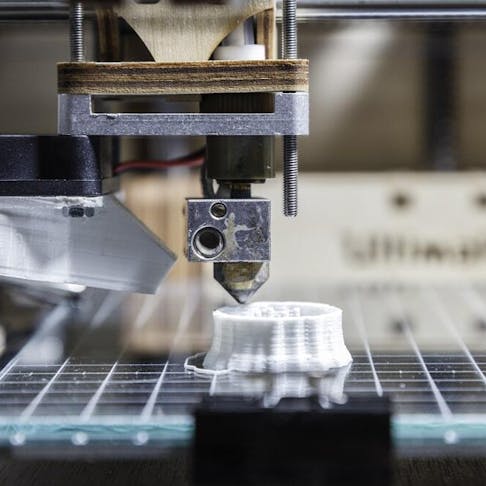

A 3D printer is a machine that creates 3D objects from digital models. These machines can be used to make a variety of things including toys, jewelry, and even medical implants. Some people use them to create new parts for their cars and homes. Users can build intricate designs that would otherwise take hours or days to create with traditional methods of production such as subtractive machining.

For more information, see our guide on 3D Printing.

What Determines a Good 3D Printer?

To understand what makes a good 3D printer, we first need to understand how they work. There are many different types of 3D printers because additive manufacturing can be done using multiple types of materials and curing methods. Each type has its strengths and weaknesses. The best 3D printer for you depends on the traits your printed parts need to have.

What Are the Various 3D Printer Types Available?

Table 1 below highlights the various types of 3D printers available in the market today:

| Types | Definition | Differences | Example Uses |

|---|---|---|---|

Types SLA - Stereolithography | Definition Select portions of a photosensitive resin are exposed to a UV light that cures it. | Differences Uses a bath of photosensitive resin. | Example Uses Conceptual designs or cosmetics prototypes. |

Types SLS - Selective Laser Sintering (SLS) | Definition Prints both metals and polymers. A part is made by sintering successive layers of powder with a laser. | Differences Employs a powder bed. | Example Uses Prototypes and functional components. |

Types FDM (Fused Deposition Modelling) or Material Extrusion | Definition This technique makes use of a spool of thermoplastic filament. The filament is melted and extruded through a nozzle in the proper path to lay down each layer. | Differences Uses a spool of filament made of thermoplastic. | Example Uses Packaging for food and medication. |

Types Powder Bed Fusion (PBF) or SLM (Selective Laser Melting (SLM) | Definition The majority of high-strength applications use this highly effective method. A thin layer of metal powder is melted one layer at a time until the entire solid structure is created. | Differences Makes use of a fine metal powder. | Example Uses Creates functional prototypes as well as medical prostheses and end-use components. These parts are stronger than sintered metal. |

Types Laminated Object Manufacturing (LOM) or Sheet Lamination | Definition A sequence of thin layers are produced via subtractive means and then glued to one another. The technique makes use of a laser beam or other tool to perform the cutting. | Differences Utilizes laminates of plastic, paper, or metal with adhesive coating. | Example Uses For creating plastic part prototypes. Can produce low-cost, striking 3D advertising goods. |

What Are the Most Used 3D Printing Materials?

Some of the most-used printing materials are:

- Nylon: Nylon is a very strong, heat-resistant material that’s often used to create durable products. It’s regularly seen in 3D-printed clothing and is great for building prototypes. Nylon is generally a more advanced type of 3D printing material since it requires a heated bed.

- ABS: One of the earliest and most prominent thermoplastics used with commercial 3D printers is ABS (Acrylonitrile Butadiene Styrene). The advantages of ABS include its inexpensive cost, excellent mechanical qualities, toughness, and superior impact resistance. These characteristics make ABS a viable choice for situations where parts need to be strong and able to withstand additional use.

- PLA: PLA (polylactic acid) is a biodegradable thermoplastic that’s made from renewable resources like corn and sugarcane. It’s a good material to use if you’re just getting started with 3D printing. PLA is great for smaller items like figurines and decorations that don’t require a lot of strength.

How Much Does a 3D Printer Cost?

A 3D printer's cost will vary depending on the quality and type. For example, if you’re looking for a 3D printer for home use, you typically have two options: buy a new one or build a kit. A mid-range 3D printer can cost between $300 and $1,000. However, there are also cheap models available for under $100. The more features a printer has, the more expensive it will be.

Is it Less Expensive to Build a 3D Printer Than to Buy a Brand-new One?

Yes, it is less expensive to build a 3D printer than to buy a pre-made one. You’ll need to find a model that’s open-source and made of parts you can easily attain. You’ll also need to find a parts list, wiring diagrams, and assembly instructions online. Building your 3D printer will give you full control over every aspect of it, including the ability to add new features or upgrade parts as they become available.

Summary

This article presented ten things to consider when buying a 3D printer, explained what they are, and discussed how each is important for your needs. To learn more buying 3D printers, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.