Without knowing how a material reacts to tension, or how much of it it can take, your engineered products and structures can fail and leave you scratching your head. A great way to avoid this is via a stress-strain curve graph that provides a visual explainer of a material’s qualities and how it will respond to various stressors. We’ll explain exactly how the graph works and how you can read it in this article.

What is Stress?

There are many types of stress, but when it comes to the type engineers are working to discover, the simplest definition is the amount of force that gets applied to a cross-sectional area. Knowing this gives you an understanding of how much a material can handle before it fractures or breaks. The formula for figuring it out can be seen below:

Stress formula.

- 𝜎 = stress

- F = applied force

- A = cross-sectional area

To learn more, see our article on Stress.

What is Strain?

Although stress and strain are often talked about together, the latter is the deformation a material goes through compared to its original dimensions. It’s another calculable reference point that’s essential for helping engineers really know a material better, and get the best idea of when a structure or item made of a specific material will break. Strain is an example of a unitless value (as both the numbers in the formula are lengths), and the formula looks like this:

Strain formula.

- ε = strain

- Lf = final length after the deformation happens

- L0 = original or starting length

To learn more, see our full guide on Strain.

What is the Stress-Strain Curve?

Now we’re going to take a look at measuring the stress-strain curve and what kinds of information can be pulled from it. In manufacturing today, there are many machines that do all the measuring for you. These curves usually are created by a modern tensile testing machine, and the said graphs are standardized through ASTM International under a few categories—E8 for metals and D638 for plastics. You can expect tests and measurements to create this curve to go something like this:

- You or the operator will source or create a test material with the right dimensions.

- Then you’ll clip or attach the test material to the jaws of the testing machine.

- The machine will then place a tensile load onto the material and increase that load until the material breaks.

- Once this happens, the machine will note the stress and strain values based on those readings.

Why Are Stress-Strain Curves Important?

The stress-strain curve is important because it allows engineers to quickly determine several of the most critical and fundamental mechanical properties of any material. A single tensile test can produce a stress-strain graph, which then allows the following properties of a material to be obtained:

- Young’s modulus

- Yield strength

- Ultimate tensile strength

- Ductility

- Poisson’s ratio

How Are Stress-Strain Curves Generated?

Stress-strain curves are generated automatically by modern tensile testing machines. These machines continuously monitor and record the force applied to a test specimen and the amount of deformation it experiences as a result of that load. The most commonly used test methods for tensile testing and creating standardized stress-strain curves are those issued by ASTM International. ASTM E8 standardizes tensile tests for metallic materials while ASTM D638 standardizes tensile tests for plastic materials. The steps to creating a stress-strain curve are described in the list below:

- Prepare the test specimen to the required dimensions.

- Mount the test specimen in the jaws of the tensile testing machine.

- Apply a continuously increasing tensile load to the specimen until it breaks.

- The tensile testing machine will record the stress and strain experienced by the test specimen based on readings of force applied by the load cell and displacement of the jaws holding the test piece.

What Are the Different Ways to Measure Stress and Strain?

There are two types you’ll find on the stress-strain curve, engineering stress and strain, and true stress and strain.

1. Engineering Stress and Strain

The first type (engineering) is also called nominal stress and strain and is calculated without considering the very small details of plastic deformation. It’s an easy way to get values through a standard tensile test and understand the performance of a material. The formula for engineering stress looks like this:

Engineering stress formula.

A0 stands for the original cross-sectional area of your test material, and both the Pascal (Pa) and pounds per square inch (psi) are used as units. The formula for engineering strain looks like the following and is a unitless measurement:

Engineering strain formula.

2. True Stress and Strain

This is the actual stress and strain value you get if you take plastic deformation into account. Doing calculations for this specific type of stress and strain is great for learning the mechanical properties of a material, and to find it you need to use experimental data on the instantaneous gauge length, cross-sectional area, and applied load. The formula for finding true stress looks like this:

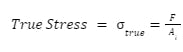

True stress formula.

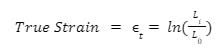

Ai stands for the instantaneous cross-sectional area. To then find the true strain, use the formula below, where Li stands for instantaneous length:

True strain formula.

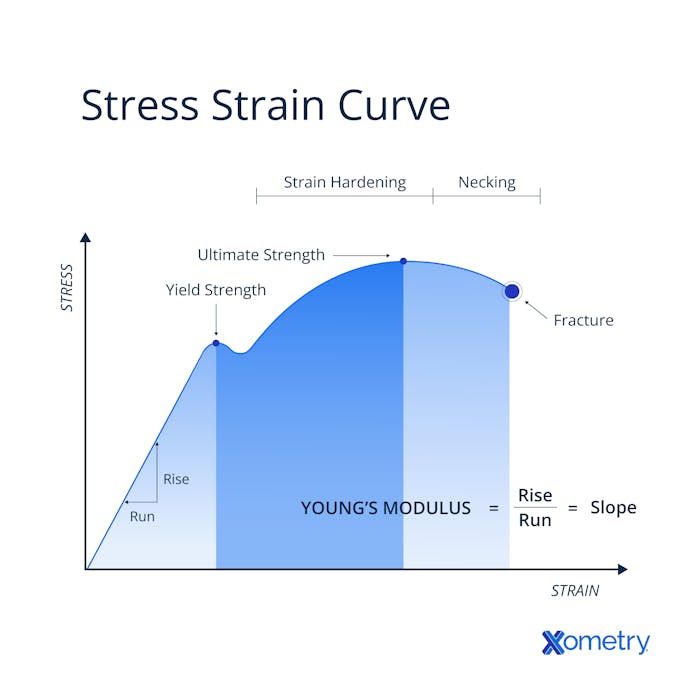

What Are the Stages of the Stress-Strain Curve?

A stress-strain diagram has three stages. In the first stage, the material experiences only elastic deformation. When the applied stress is released, the material returns to its original dimensions.

Uniform plastic deformation takes place in the second stage. This stage begins at the yield point and continues for as long as the material can continue to strengthen through strain hardening (the same process that occurs in cold forming) with every new increment of the applied load. Eventually, the material's capacity for stable plastic deformation is exhausted. The amount of plastic strain that can be tolerated during this phase tells us a lot about the material's relative brittleness or ductility.

The final stage of a tensile test is referred to as “necking.” This stage occurs after the material’s ultimate tensile stress is reached, and no further strain hardening is possible. Instead of continued, stable deformation, a region of localized deformation forms somewhere in the cross-section of the test specimen. The excessive tensile stresses reduce the material’s dimensions that are perpendicular to the applied force which causes a significant reduction in area. This makes the material have the shape of a “neck”. Once necking begins, the engineering stress of the material decreases while the true stress continues to increase. The material fractures soon after necking begins.

How Do You Read a Stress-Strain Graph?

Here’s a quick guide to reading one of these graphs:

- Choose a stress value on the Y-axis.

- Draw a horizontal line from the Y-axis until it intersects with the line of the stress-strain curve. Make a dot on that point.

- Draw a vertical line from the intersection point to the X-axis. Together, these lines should form a 90-degree angle.

- The stress value you picked in step one shows the stress that corresponds to the deformation (or strain) that happens to the material at that point.

What Are the Different Regions of the Stress-Strain Curve Graph?

Once you have a graph showing the stress-strain curve, it’s worth understanding the regions, stages, and information you can parse from it. The three stages are elastic deformation, uniform deformation, and necking. Elastic deformation is when a material experiences stress but can still snap back to its original dimensions. Uniform deformation happens for as long as a material can handle strengthening through strain hardening—which is a show of its brittleness or ductility. Necking is when the ultimate tensile strength has been reached and strain hardening isn’t possible anymore. Localized deformation will appear somewhere in the material’s cross-section, its dimensions decrease while stress increases, and then it’s past the point of no return and deforms or breaks permanently.

Now that you know the stages, you can understand the regions and pick out five of the most important points on the graph, which we’ve briefly described below:

1. Proportional Limit

The end point of the linear portion on the stress-strain curve which Young’s modulus can be pulled from by calculating the slope.

To learn more, see our article on proportional limit.

2. Elastic Limit

The end point for elastic deformation, which is then taken over by plastic deformation (it’s hard to distinguish it from the elastic limit when you’re measuring metals).

To learn more, see our article on elastic limit.

3. Yield Point

The same as the elastic limit, but calculable, so much more reliable for engineers. To work it out, offset the linear portion of the curve by +0.2% along the horizontal axis. Then, you find the intersection point between the offset line and the original stress-strain curve, and you have the yield strength.

To learn more, see our full guide on yield point.

4. Ultimate Stress Point

The highest amount of stress on the stress-strain curve, after which necking starts. It’s also important to note that while this is the highest on the graph, the actual highest point happens right when the material breaks.

5. Fracture or Breaking Point

As its name says, this is the point on the curve where your material has deformed so much it has finally broken or fractured.

To learn more, see our full guide on fracture or breaking point.

How is a Stress-Strain Curve Made?

A stress-strain curve is made by conducting a tensile test using a universal testing machine. The testing machine will automatically capture the data to produce a stress-strain curve as the load increases and the specimen deforms.

How Are Stress-Strain Curves Used?

The stress-strain graph is used to determine various mechanical properties of a material, including elastic modulus, Poisson’s ratio, yield stress, and ultimate tensile strength. These properties help engineers select materials for applications where load-bearing capability is critical.

What Is the Stress-Strain Curve of a Ductile Material?

The engineering stress-strain curve for a ductile material is characterized by an increasing straight line until the yield point is reached. After the yield point, the function of stress and strain increases non-linearly and peaks when the ultimate tensile strength is reached. Afterward, the engineering stress non-linearly decreases as the strain continues to increase. Eventually, once the material’s strain has become so large, the material fractures.

To learn more, see our full guide on ductility.

What Is the Stress-Strain Curve of a Brittle Material?

The stress-strain curve of a brittle material is a steeply sloped line that shows the stress increasing rapidly with little strain. Unlike ductile materials, the stress-strain curve for a brittle material shows little plastic deformation after the yield stress (yield point) is reached. The material fractures soon after the yield stress.

To learn more, see our full guide on brittleness.

What Is the Difference Between Engineering Stress-Strain and True Stress-Strain?

The differences between engineering stress-strain and true stress-strain are listed below:

- Engineering stress-strain doesn’t take into account the material’s deformation while true stress-strain does.

- Engineering strain is the ratio of the change in length to the original length while a true strain is the natural logarithm of the instantaneous length over the original length.

- Engineering stress-strain is ideal for determining material performance while true stress-strain is ideal for determining material properties.

What Is the Difference Between Stress and Strain?

The differences between stress and strain are listed below:

- Stress is the force per unit area, while a strain is a variation in the length of a dimension over the original length of the dimension.

- Stress has units of Pa or psi while a strain is unitless.

- The symbol for stress is 𝛔 while the symbol for strain is 𝞊.

- Stress is required to cause strain.

- Stress cannot be directly measured and is calculated through mathematical relations while a strain can be directly measured.

To learn more, see our full guide on stress vs. strain.

How Xometry Can Help

We at Xometry work with many different materials that are important to engineers and manufacturers and can offer free quotes for everything from CNC machining to 3D printing to sheet laser cutting.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.