Low-pressure (LP) casting has become the most common and reliable technology for producing aluminum alloy components in industries ranging from automotive to aerospace. Compared with traditional methods such as sand casting or gravity die casting, LP casting offers superior control over metal flow, improved structural integrity, and enhanced mechanical properties.

This article explores the fundamentals of LP casting��—its definition, historical development, working principles, advantages, disadvantages, and applications in modern manufacturing.

What Is Low-Pressure Casting?

Low-pressure casting (LP casting) is a metal casting process that introduces molten metal into a mold under relatively low pressure, typically not exceeding 0.8 bar (approximately 11.6 psi). This technique is particularly beneficial for creating high-quality castings with improved mechanical properties compared to other methods, such as sand casting. Unlike gravity die casting, low-pressure die casting is performed with the mold positioned at or above the level of the molten metal.

Low-pressure casting produces stronger parts than conventional sand casting. This is because the slow, turbulence-free entry of liquid metal into the mold reduces porosity due to trapped gases and solidification shrinkage. In addition to the benefits of pressurized mold filling, low-pressure casting dies contain integral cooling passages that aid in controlled cooling, further enhancing mechanical properties.

What Is the History of Low-Pressure Casting?

The origins of low-pressure casting trace back to the early 20th century. In the early 1900s, S.P. Wetherill and J.P. Wetherill Jr. in the U.S. pioneered the field by patenting low-pressure metal mold casting equipment for zinc-aluminum alloy parts in 1906. Concurrently, A.L.J. Queneau in West Germany explored the application of a resistance crucible furnace for casting aluminum bronze and manganese bronze in 1910; meanwhile, E.F. Lake in Britain patented equipment for lead and tin alloys around the same time.

In 1917, France introduced a groundbreaking low-pressure casting machine utilizing pressure generated through water evaporation. Despite these advancements, the technique experienced limited industrial utilization in subsequent decades. However, low-pressure casting emerged as a solution to address the wall thickness effect in heavy-section aluminum alloy castings post-World War II.

E.C. Lewis from British Alumasc furthered the research in the post-war era, achieving significant milestones like producing a light alloy beer barrel in 1950. Beyond the 1960s, low-pressure casting continued to evolve and expand its influence worldwide. Early adopters like Britain, the United States, Japan, and West Germany propelled the technique's popularity, particularly in producing aluminum alloy wheel hubs. Technological progress in machinery and processes further improved its capabilities.

What Is the Importance of Low-Pressure Casting in Manufacturing?

The significance of low-pressure casting in manufacturing is based on its ability to produce high-quality and intricate metal parts, particularly in aluminum alloys. The precisely controlled filling of the mold cavity reduces turbulence due to the smoother flow of the metal. This reduces gas entrapment and therefore makes the casted products less porous, ensuring superior part quality. This controlled process also allows for the production of complex geometries, including relatively thin walls (about 3 mm) and intricate details. With reduced machining requirements, improved metallurgical properties, and compatibility with automation, low-pressure casting emerges as a versatile and valuable manufacturing technique.

How Does Low-Pressure Casting Work?

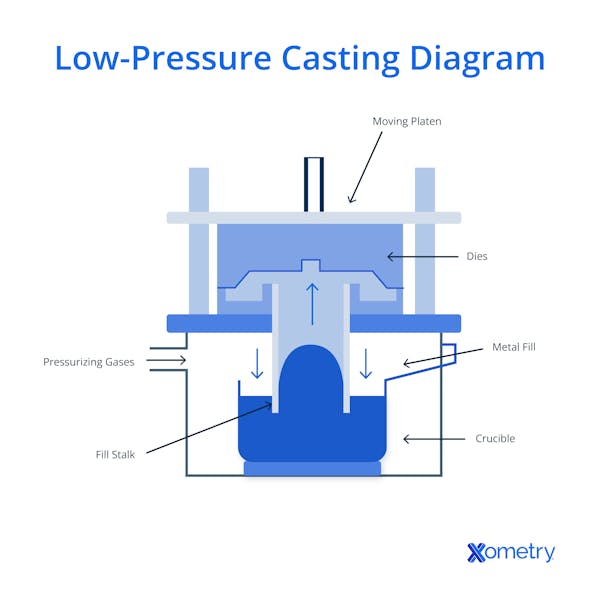

Low-pressure casting works by methodically introducing molten metal into a mold under controlled, low-pressure conditions.

The process begins with machining a mold from materials like steel or sand to replicate the intended part's shape and attributes. Permanent molds are more frequently employed than sand molds due to their greater productivity potential. This mold is carefully sealed to prevent any undesired air ingress. Before molten metal enters the mold, specific pre-casting processes may be performed. The mold might be preheated to prevent thermal shock, and fluxes could be employed to clean its surface and to avoid oxidation. Degassing procedures may also be carried out before casting to eliminate trapped gases.

Once these preliminary steps are complete, the metal is elevated to a temperature surpassing its melting point within a furnace. Subsequently, the molten metal is conveyed to a holding furnace (crucible) responsible for sustaining the temperature and eliminating any impurities present in the metal. The stove is then pressurized. The molten metal enters the mold cavity steadily. This controlled process is characterized by a lack of turbulence due to the low applied pressure. Before solidification begins, air within the mold can escape through strategically placed vents.

During the cooling phase, the molten metal gradually solidifies, conforming precisely to the shape of the mold cavity. Throughout this process, the applied pressure is maintained to fill any potential shrinkage pockets and guarantee that the solidifying metal fully replicates all intricate details of the mold. Once the metal has sufficiently cooled and solidified, the mold is opened, and the resulting casting is carefully removed. Depending on the complexity of the part, further processes such as trimming, machining, and finishing may be conducted to achieve the desired final product.

What Makes Low-Pressure Casting Stand Out Among Other Types of Casting?

Low-pressure casting excels at producing high-quality castings with low levels of porosity due to gas entrapment. This can be attributed to the low-turbulence, controlled mold-filling process combined with sustained pressure to fill voids from shrinkage during cooling. Furthermore, this casting method yields parts with smoother surface finishes than traditional sand casting techniques. The forte of low-pressure casting lies in its ability to reproduce intricate shapes with fine details and wall thicknesses as low as 3 mm. This casting technique is also gentle on molds and dies, extending their lifespan and minimizing maintenance costs.

To learn more, see our guide on Types of Casting Methods.

What Is the Process of Low-Pressure Casting?

Below is a detailed step-by-step breakdown of the low-pressure casting production cycle:

1. Melt the Metal Alloy in a Furnace to the Required Casting Temperature

The process begins by melting the selected metal alloy—commonly aluminum or magnesium—in a melting furnace. The alloy is heated until it reaches its casting temperature, which must be slightly above the alloy’s liquidus point to ensure complete fluidity for mold filling.

The exact casting temperature depends on several factors, including:

- The alloy's chemical composition and melting range

- The thermal characteristics of the mold

- The complexity and thickness of the casting

Note: Proper temperature control is critical to avoid defects such as cold shuts or incomplete filling.

2. Transfer Molten Metal to a Pressurized Holding Furnace Beneath the Mold

Once molten, the metal is transferred into a holding furnace located beneath the mold. This furnace maintains the alloy at the target temperature and positions it for upward delivery into the mold cavity. This setup minimizes oxidation and enables direct pressurization of the metal for casting.

3. Apply Low Pressure to Feed Molten Metal into the Mold via Riser Tube

Low pressure, typically between 0.3 and 0.7 bar, is applied to the holding furnace to push the molten metal upward through a refractory riser tube into the mold. The flow is gradual and laminar, which minimizes turbulence and air entrapment, allowing the metal to fill the mold evenly from the bottom up. This step is critical for achieving defect-free castings, especially in parts with complex geometries or thin walls. The pressure is maintained throughout mold filling and the early stages of solidification to compensate for any volume shrinkage.

4. Maintain Pressure During Solidification in the Die Cavity

As the metal cools and begins to solidify, the applied pressure continues to ensure that the mold remains filled despite shrinkage. This results in improved density, uniform microstructure, and reduced porosity in the final part. Controlled solidification also enhances mechanical properties and dimensional accuracy.

5. Release Pressure and Recycle Excess Molten Metal

After solidification is complete, the pressure is released. Any remaining molten metal in the holding furnace or riser system is retained for reuse in the next casting cycle. This closed-loop system minimizes material waste and improves process efficiency.

6. Cool and Open the Mold to Casting Removal

The mold, now containing the solidified cast component, is allowed to cool down. Cooling helps complete the solidification process and enhances the overall integrity of the cast part. Once sufficiently cooled, the mold is opened, and the finished casting is removed.

Working with low-pressure casting often reshapes assumptions about process control in metal fabrication. What initially appears to be a simple adjustment in mold-filling pressure reveals itself as a methodical approach to reducing porosity, managing solidification, and improving microstructure. The process demonstrates that consistent quality in cast components depends as much on controlled flow and thermal gradients as on alloy selection. Over time, low-pressure casting has evolved from a method of replacing other casting processes to one that enables reliable performance in demanding, high-integrity applications.

What Are the Metals Used in Low-Pressure Casting?

The low-pressure casting process is suitable for producing components from a range of non-ferrous metals. It is particularly effective for metals that require precise control of fill and solidification, and it is commonly used to manufacture high-integrity castings with excellent surface finish and dimensional accuracy.

Among the metals frequently used in low-pressure casting are:

1. Magnesium Alloys

Magnesium alloys are utilized in low-pressure casting for applications where low density and a high strength-to-weight ratio are essential. These alloys are especially valued in industries such as aerospace, automotive, and consumer electronics due to their lightweight and mechanical performance. In the automotive sector, magnesium components help reduce vehicle weight, contributing to improved fuel efficiency and reduced carbon emissions. Typical cast components include gearbox housings, steering wheel components, instrument panel supports, and other structural or semi-structural elements.

2. Aluminum Alloys

Aluminum and its alloys are the most commonly used materials in low-pressure casting, due to their favorable casting characteristics, excellent strength-to-weight ratio, and natural resistance to corrosion. The LPC process is particularly suited for medium-to-large structural components that require high-dimensional accuracy and a sound microstructure, making aluminum alloys a preferred choice across multiple industries.

Key industries that utilize aluminum low-pressure castings include automotive, aerospace, and consumer electronics. In the automotive industry, aluminum is used for parts such as wheel hubs, engine blocks, cylinder heads, suspension components, and transmission housings, contributing to significant vehicle weight reduction and improved fuel efficiency. In consumer electronics, aluminum is frequently used for enclosures and structural casings in products like laptops, tablets, and smartphones, where it offers a balance of strength, lightness, heat dissipation, and aesthetic finish.

3. Copper and Copper Alloys

Copper and its alloys are less frequently used in low-pressure casting due to their relatively high melting points, typically above 1,080°C (1,976°F). This elevated temperature requires greater energy input, specialized refractory materials, and careful process control. Additionally, copper’s high thermal conductivity, while advantageous for end-use applications, can lead to uneven cooling rates, thermal stress, and increased risk of mold cracking—particularly when using traditional mold materials. The oxidation susceptibility of copper at elevated temperatures also poses challenges during casting, necessitating inert gas atmospheres or flux protection to prevent surface degradation and preserve casting quality. Additionally, copper alloys often have lower fluidity than aluminum or magnesium alloys, limiting their effectiveness in filling intricate mold geometries unless optimized gating and riser systems are used.

Despite these challenges, copper alloys are valued for their electrical and thermal conductivity, making them suitable for applications in electronics and telecommunications. In the electronics and telecommunications sectors, low-pressure cast copper components may be used for heat sinks, electrical connectors, terminal blocks, and other precision components requiring efficient thermal management and conductivity.

4. Zinc and Zinc Alloys

Zinc alloys are primarily associated with high-pressure die casting due to their excellent castability, low melting points (typically around 385°C or 725°F), and exceptional dimensional stability. Zinc alloys exhibit excellent fluidity, making them ideal for producing components with complex geometries and fine surface details. They also provide good mechanical strength, corrosion resistance, and the ability to maintain tight tolerances, which is especially valuable for precision hardware. These alloys are used in applications having intricate shapes, for decorative pieces, and for hardware. A notable application is in the production of door handles and hardware, where zinc alloys can be intricately cast into detailed designs while maintaining durability and corrosion resistance.

Can Steel Be Used as a Casting Metal for Low-Pressure Casting?

No. Steel is less frequently associated with low-pressure casting due to its notably high melting point and the distinctive challenges this characteristic presents within the low-pressure casting process. This divergence arises from the significant temperature disparities between steel and metals like aluminum, magnesium, and zinc, which are more commonly used in low-pressure casting. The elevated melting point of steel necessitates specialized equipment and techniques, including high-temperature molds and advanced temperature management systems, to address the complexities of the low-pressure casting process.

What Are the Applications of Low-Pressure Casting?

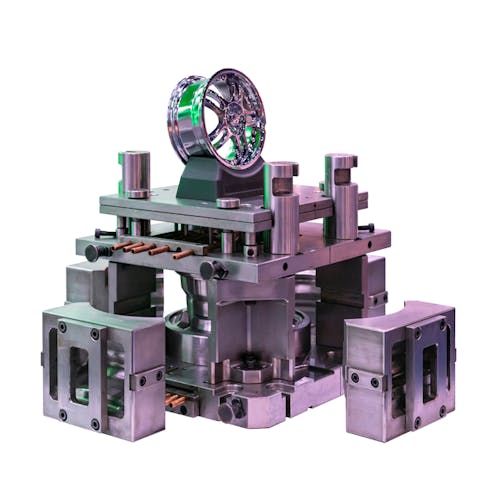

Low-pressure casting is mainly used for the manufacture of complex, high-quality components. These include aluminum alloy engine blocks and suspension components for cars, cylinder heads, aluminum wheels, heat sinks for electronic components, pump housings, impellers, and even golf club heads. LP casting is suitable wherever complex geometry and intricate designs need to be produced.

What Industries Use Low-Pressure Casting Products?

Low-pressure (LP) casting is used in a range of industries thanks to its efficiency and ability to produce high-quality aluminum components. The automotive sector is the largest user, applying LP casting to wheels, cylinder heads, and suspension parts where strength and precision are vital. Aerospace also relies on the process for structural and engine components, which must be lightweight yet highly reliable. Beyond transportation, LP casting is found in sports equipment such as tennis rackets and bicycle frames, where a balance of durability and low weight is needed. It is also applied in household appliances, including washing machines, vacuum cleaners, and cooking equipment, where components must withstand repeated stress. In industrial machinery, parts such as impellers, pump housings, and gearbox casings are commonly produced using this method. Altogether, LP casting supports industries that demand strong, lightweight, and consistent components, making it one of the most versatile manufacturing processes for aluminum alloys.

What Is the Quality of Low-Pressure Casting Products?

Low-pressure casting is recognized for producing high-quality aluminum components with excellent strength and dimensional accuracy, typically within tolerances of ±0.005 inch for the first inch and ±0.003 inch for each additional inch. This high level of precision comes from the controlled mold-filling process, which minimizes turbulence and reduces the risk of porosity and oxide formation. As a result, castings exhibit a low defect rate, consistent microstructure, and uniform mechanical properties across the entire part. These qualities make low-pressure casting a preferred method in industries that demand reliability, repeatability, and performance.

Are the Low-Pressure Cast Products Durable?

Yes, low-pressure casting products can be durable and exhibit good mechanical properties when the process is executed correctly. The controlled nature and reduced turbulence of the low-pressure casting process routinely deliver high-quality castings with decreasing levels of defects such as porosity caused by gas entrapment or shrinkage. Note that the durability of low-pressure casting products will also depend on factors such as the choice of material, proper design and engineering, post-casting heat treatment (if required), and the specific conditions under which the products will be used. As with any manufacturing process, the quality of the casting and the attention to detail throughout the production process will play a significant role in determining the final durability of the product.

What Is the Accuracy of Low-Pressure Casting?

Low-pressure casting produces higher-quality castings in comparison to traditional gravity casting methods. The carefully regulated and uniform flow of metal, combined with reduced turbulence, results in enhanced dimensional accuracy. The typical dimensional tolerance for low-pressure casting components is approximately ±0.005 inch (±0.127 mm) for the first inch, and ±0.003 inch (±0.076 mm) for each additional inch, depending on the alloy, mold design, and part complexity. To aid in mold release and ensure proper component ejection, a minimum draft angle of 0.5 degrees is generally recommended. Low-pressure casting also allows for near-net-shape production with minimal machining, which makes it ideal for medium-to-large components requiring tight dimensional control and structural reliability.

What Is the Lifespan of Low-Pressure Casting Products?

Die cast molds are expected to last between 80,000 and 100,000 casting cycles. When low-pressure casting is performed with proper techniques and attention to detail, the resulting products can have a long and reliable lifespan. The carefully regulated and uniform flow of metal, combined with reduced turbulence of the casting process, often leads to parts with good mechanical properties and reduced porosity, contributing to their durability. However, the lifespan of low-pressure casting products can vary widely based on multiple factors. These include the type of material used, the quality of the casting process, the design and engineering of the product, the specific application and conditions in which the product is used, and the level of maintenance and care provided throughout its service life.

What Are the Advantages of Low-Pressure Casting?

Low-pressure die casting (LPDC) offers a host of advantages, as listed below:

- Exhibits high accuracy as a result of maintaining low pressure during solidification.

- Minimizes inclusions from oxidation or trapped slag.

- Introduces molten metal to the mold without turbulence. Avoiding churning and splashing the liquid metal helps to prevent oxide formation, which, in turn, leads to a lower level of unwanted inclusions in the final casting.

- Produces castings with minimal porosity by employing low pressure.

- The regulated flow and solidification of metal enhance the mechanical attributes of the castings.

- Controlled mold filling results in fewer casting flaws and, consequently, less material discarded as scrap.

- Can accommodate a diverse array of non-ferrous alloys, such as magnesium, aluminum, and zinc.

What Are the Disadvantages of Low-Pressure Casting?

While the low-pressure die-casting process is renowned for its dimensional accuracy, it does also have some drawbacks:

- It takes longer to fill a given mold shape than with other casting processes, such as high-pressure die casting.

- The potential for erosion within the aluminum casting form primarily emerges from the interaction between the molten metal and the metal components of the equipment. This phenomenon of erosion typically affects components such as the crucible and riser. While erosion of the aluminum casting itself is not a common issue, localized erosion might occur in areas of high turbulence, such as near the entry point or other critical regions of the mold.

- Requires a minimum wall thickness of around 3 mm.

- Although low-pressure casting typically demands less energy than some alternative casting methods, such as high-pressure die casting and sand casting, it does exceed the energy consumption of more straightforward techniques, such as gravity casting.

- A substantial upfront financial commitment is required to procure specialized equipment and tooling. The expenses encompass the acquisition of the low-pressure casting machine, mold preparation, and additional ancillary equipment.

- The systems that control casting metal temperature and application of pressure for mold filling require skilled operators with appropriate training.

How Much Does Low-Pressure Casting Cost?

The cost of parts manufactured by low-pressure casting can vary significantly based on several factors, including the size and complexity of the part being cast, the type of material used, the size of the production run, the quality requirements, and the specific equipment and facilities available.

Generally, low-pressure casting can be more cost-effective than some other casting methods, like high-pressure die casting, due to its reduced need for extensive tooling and its ability to produce high-quality castings with less porosity. While it still necessitates essential components like furnaces, liquid metal transfer systems, molds, and controls for temperature and pressure, LPDC does not need complex and costly die shot equipment and associated maintenance. The cost of low-pressure casting machines typically falls in the range of $30,000 to $50,000. The piece price of cast products can range from as low as $1 to several thousand dollars. However, the exact cost would depend on the unique circumstances of each casting project. It's recommended to obtain quotes from casting service providers or manufacturers to get a more accurate estimate based on your specific requirements.

Is Low-Pressure Casting More Expensive Than High-Pressure Die Casting?

It depends. High-pressure die casting represents a significant investment, whereas opting for low-pressure die casting offers a more cost-effective alternative. Additionally, the high-pressure process is confined to smaller parts due to limitations imposed by the locking mechanism's capacity, which can only accommodate weights up to a certain threshold. High-pressure die casting is also cheaper for high-volume productions.

What Are the Alternatives for Low-Pressure Casting?

The main alternatives to low-pressure casting are listed below:

- Gravity Casting: In this approach, molten metal is poured into a mold using only the force of gravity. Gravity casting relies on the natural flow of metal due to gravity, which can result in slower filling times and may require thicker mold sections to counteract turbulence. Conversely, low-pressure casting, as its name suggests, employs controlled pressure to enhance mold filling speed and enable the production of parts with intricate features and thinner walls. What also sets gravity casting apart from low-pressure casting is its ability to accommodate a broader range of materials. While low-pressure casting primarily uses aluminum alloys, gravity casting supports various material choices.

- Investment Casting (Lost Wax Casting): This method involves creating a wax pattern that replicates the final product's shape and is then covered in a ceramic slurry to make a mold with controlled thickness. Investment casting offers greater precision than low-pressure casting, attributed to its use of precisely crafted wax patterns.

- Sand Casting: Traditional sand casting involves making a pattern, forming a mold from a mixture of sand, water, and a binder, usually clay, filling it with molten metal, and ultimately removing the mold. The choice between die casting and sand casting depends on the type of metal being used. Sand casting is notably preferred for its cost-effectiveness, particularly when dealing with materials like steel and cast iron. The process allows for the production of larger and more intricate parts with relatively lower tooling expenses. However, it's important to note that sand casting can yield rougher surface finishes and may necessitate thicker walls compared to die casting. Sand casting is also preferable over low-pressure casting when working with high-temperature metals.

What Is the Difference Between Low-Pressure Casting and High-Pressure Casting?

Low-pressure casting and high-pressure casting are two distinct methods employed in metal casting. The main difference is that low-pressure casting is generally conducted at pressures below 0.8 bar, ranging up to 1 bar in some cases. High-pressure casting, on the other hand, involves significantly elevated pressures, frequently exceeding 1000 bars.

The mechanical strength of the resulting cast parts is another point of difference. Components manufactured using low-pressure casting demonstrate elevated strength characteristics owing to their extended solidification duration, accompanied by consistent pressure application. This combination of factors facilitates the formation of a more refined microstructure within the cast material, contributing to increased strength. On the other hand, components produced through high-pressure casting also possess commendable strength attributes; however, they encounter challenges in reaching the equivalent strength levels achieved by their low-pressure counterparts.

The desired part thickness plays a significant role in choosing between the two methods. Low-pressure casting excels in producing thick parts, yet is ill-suited for thin-walled components (less than 3 mm). On the other hand, high-pressure casting helps make thin-walled parts (down to 0.40 mm).

To learn more, see our article on High-Pressure Casting.

Summary

This article presented low-pressure casting, explained it, and discussed its importance and advantages. To learn more about low-pressure casting, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including casting and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.