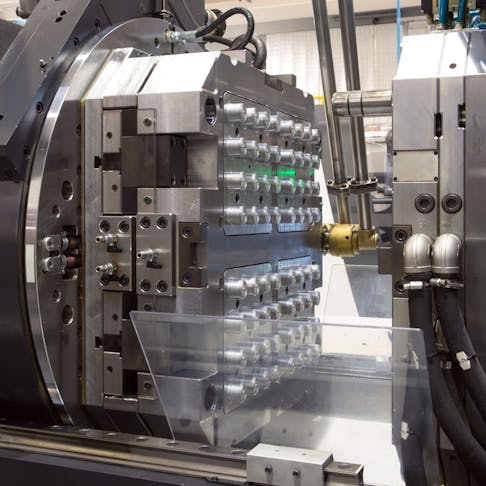

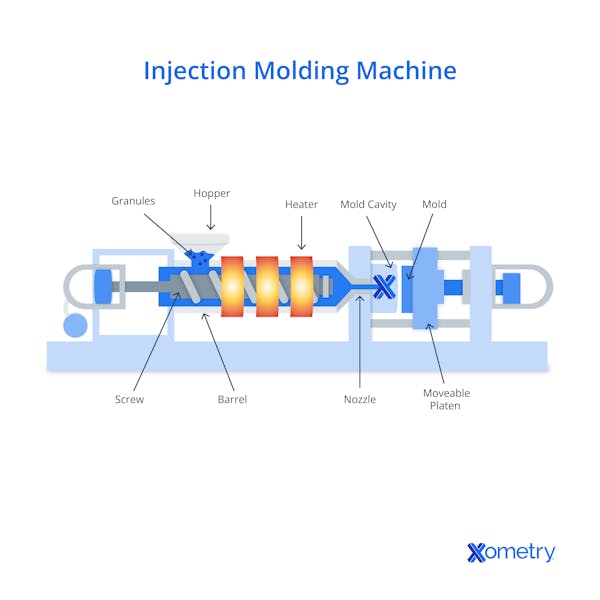

The 10 main parts of an injection molding machine are the hopper, barrel, reciprocating screw, heaters, nozzle, ejector pins, mold (core and cavity), clamping unit, injection unit, and hydraulic unit, which all work together to produce molded plastic parts. An injection molding machine is a device used to produce plastic products by injecting molten plastic into a mold. The machine is essential in automotive, medical, and consumer goods for producing high-quality injection molded parts. Each part of the injection molding machine plays a unique role in the process, ensuring the efficient production of parts. Understanding the 10 parts of an injection molding machine is important for the effective operation and maintenance of the machine. The parts work in unison to create high-quality injection molded parts that are used in countless products across industries. The efficiency and precision of each component are vital for successful injection molding machine operations.

The 10 parts of an injection molding machine are listed below.

- Hopper: The hopper is a container that stores plastic pellets or granules and feeds them into the barrel. It serves as the starting point for the material in the injection molding process.

- Barrel: The barrel is the main chamber where the plastic pellets are melted. The plastic is subjected to heat and pressure inside the barrel to reach a molten state suitable for injection into the mold.

- Screw Motion or Reciprocating Screw: The reciprocating screw plays a crucial role in moving the molten plastic from the barrel to the mold cavity. It ensures consistent material flow and pressure to guarantee proper filling of the mold.

- Heaters: Heaters are strategically placed along the length of the barrel to maintain a specific temperature that ensures the plastic melts uniformly and reaches the proper consistency for injection.

- Nozzle: The nozzle is a small opening at the end of the barrel where the molten plastic is forced through under high pressure and injected into the mold cavity.

- Ejector Pins: Ejector pins are used to eject the molded part from the mold once it has cooled and solidified. They help ensure smooth and safe part removal from the mold.

- Split Molds: The mold consists of two halves (known as the "core" and "cavity") that come together to form the shape of the molded part. The mold is precisely designed to match the final product's specifications and quality.

- Clamping Unit: The clamping unit securely holds the mold halves together during the injection process, applying the necessary force to ensure that the mold stays closed under the pressure of the injected material.

- Injection Unit: The injection unit is responsible for injecting the molten plastic into the mold cavity under high pressure. It includes the screw and barrel system that melts and delivers the plastic to the mold.

- Hydraulic Unit: The hydraulic unit powers the machine’s movements, providing the necessary force for the clamping unit to operate and for the injection unit to perform the injection process. It controls the speed, pressure, and force required for various parts of the molding cycle.

Below are detailed descriptions of each of the 10 parts of an injection molding machine and their functions.

1. Hopper

The hopper serves as the storage unit for raw plastic material in the form of pellets or granules. Hopper feeds the plastic material into the barrel, where it is melted and processed into the final product. The hopper plays a vital role in maintaining the steady flow of material into the machine, ensuring that there is no interruption in the injection molding process. The machine lacks a reliable source of plastic to create the desired injection molded parts without the hopper.

The essence of the hopper lies in its ability to regulate the material input, ensuring that the right amount of plastic is available for each cycle. A properly functioning hopper prevents issues (clogging, inconsistent material flow, or contamination) that affect the quality of the injection parts. The hopper's design and efficiency directly impact the performance and reliability of the machine, contributing to the consistent production of high-quality injection parts.

2. Barrel

The barrel is a critical component of the injection molding machine, serving as the chamber where plastic material is heated and melted before being injected into the mold. Raw plastic pellets or granules are fed from the hopper into the barrel, where they are subjected to high heat and pressure. The barrel is equipped with heating elements that ensure the plastic reaches the required melt temperature and consistency. A rotating screw moves the molten material through the barrel towards the nozzle.

The barrel's primary function is to ensure the uniform melting and homogenization of the plastic, which is crucial for achieving consistent flow during injection. Any malfunction in the barrel (inadequate heating or improper material flow) results in incomplete melting, degradation of the material, or uneven infusion, all of which negatively impact the quality and precision of the molded parts. The barrel plays an essential role in producing parts that meet stringent design specifications by maintaining precise control over the temperature and pressure. Its efficiency directly influences the performance and output quality of the injection molding process, ensuring high-quality production runs.

3. Screw Motion or Reciprocating Screw

Screw motion or reciprocating screw is responsible for transporting, melting, and injecting the plastic material into the mold. The screw is a helical-shaped component that rotates within the barrel, pushing the plastic pellets forward while simultaneously applying heat and pressure to melt the material. The screw stops rotating and moves backward to prepare for the next injection cycle once the plastic is melted. The precise motion and control of the screw ensure a consistent flow of molten plastic into the mold.

The importance of the reciprocating screw lies in its ability to provide the mechanical movement needed to move plastic forward and the heat required to melt it properly. A malfunctioning screw can lead to inconsistent melting, poor material flow, and defective injection-molded parts. It plays an essential role in ensuring the correct volume of molten plastic is injected into the mold, influencing the quality of the injection parts. The screw motion is integral to the efficient production of high-precision injection parts.

4. Heaters

Heaters are essential components of the injection molding machine that are responsible for providing the necessary heat to melt the plastic material inside the barrel. The heating elements, positioned along the length of the barrel, regulate the temperature, ensuring that the plastic reaches the ideal consistency for injection. The components called “heaters,” maintain a uniform temperature throughout the barrel to prevent uneven melting, which leads to defects in the final product. The heaters ensure that the material flows smoothly, ready for injection into the mold by controlling the temperature.

The importance of heaters lies in their ability to ensure the plastic is melted evenly and consistently, which is crucial for the production of high-quality injection molded parts. The material overheats or underheats without precise temperature control, resulting in poor material flow, clogging, or incomplete filling of the mold. It negatively affects the integrity and appearance of the injection parts. The proper functioning of heaters is vital for producing precise injection parts with optimal material properties, ensuring the efficiency and reliability of the injection molding process.

5. Nozzle

The nozzle is a critical component in the injection molding process, serving as the point where molten plastic is injected into the mold cavity. The nozzle controls the flow of the melted plastic, ensuring it enters the mold precisely and evenly positioned at the end of the barrel. It helps maintain the pressure required to inject the material into intricate mold details. The nozzle is equipped with a heated tip to prevent the plastic from cooling too quickly as it exits the barrel, ensuring smooth material flow.

The nozzle's importance lies in its role in maintaining a consistent and controlled flow of molten plastic into the mold. The nozzle becomes clogged or malfunctions, leading to issues such as inconsistent filling, air pockets, or incomplete molds, resulting in defects in the final product. The nozzle plays a crucial role in maintaining the required pressure during injection, directly impacting the quality and precision of the molded parts. A properly functioning nozzle is essential for achieving optimal part characteristics and ensuring the injection molding process runs efficiently.

FREE Injection Molding Design Guide

6. Ejector Pins

Ejector pins are used to push the molded parts out of the mold cavity once they have cooled and solidified. The pins are strategically positioned inside the mold and extend outward to push the molded part out after the injection process is complete. The pins apply controlled pressure to ensure that the part is released smoothly without damaging it. They are activated by the hydraulic system of the machine, and their movement is synchronized with the mold opening.

The essence of ejector pins lies in their role in ensuring the efficient and safe removal of the molded part from the mold cavity. The part becomes stuck inside the mold without ejector pins, which requires additional force or causes damage to the part and the mold. The pins are critical for maintaining the consistency of the injection molded parts and ensuring that the parts are removed cleanly. A well-functioning ejector system helps prevent defects (surface marks or warping) in injection parts. Properly designed and maintained ejection pins are vital for achieving high-quality injection parts with minimal post-production handling.

7. Molds

The mold typically consists of two halves, known as the core and cavity, which come together to form the part’s shape and separate to allow ejection after cooling. The mold is divided into sections, typically the core and cavity, which are precisely aligned to ensure a perfect seal during the injection process. The mold opens, allowing for the part to be ejected once the molded part has cooled and solidified. The design is crucial for creating complex shapes and ensuring that the mold can be easily removed from the molded part.

The significance of molds lies in their ability to produce intricate and detailed injection-molded parts. The design facilitates easier access to the mold cavity, which helps with the smooth ejection of the part without causing damage. Molds are especially beneficial for creating parts with undercuts, varying thicknesses, or features that are difficult to form with solid molds. The precision and ease of opening and closing the mold are vital for ensuring the production of high-quality injection parts. Properly maintained molds are essential for the efficiency and consistency of the injection molding process, contributing to the creation of durable, accurate, and complex parts.

8. Clamping Unit

The clamping unit holds the two halves of the mold together under high pressure during injection, preventing gaps or leakage. The clamping unit applies the necessary force to maintain mold integrity and ensure consistent part shape. The clamping unit releases the mold to eject the finished part after injection.

The clamping unit is critical for preventing defects. Insufficient clamping force leads to incomplete parts, while excessive force can damage the mold or part. Proper clamping ensures high-quality, consistent results. A well-functioning clamping unit is essential for efficient injection molding, precise part formation, and minimizing defects.

9. Injection Unit

The injection unit is responsible for injecting the molten plastic into the mold cavity. The injection unit consists of the barrel, screw, and nozzle, which work together to melt and inject the plastic material. The injection unit is responsible for controlling the temperature, pressure, and volume of the molten plastic, ensuring that it fills the mold completely and accurately. It is a key part of the process, as the precision with which the injection unit operates directly affects the quality and consistency of the injection molded parts.

The essence of the injection unit lies in its ability to control the entire injection process, from melting the plastic to injecting it into the mold. A well-functioning injection unit ensures that the plastic is injected at the right pressure and temperature, preventing defects (incomplete filling, air pockets, or surface imperfections). The injection unit is integral to achieving the desired shape and quality in injection parts. Its role in maintaining consistent injection parameters ensures the production of high-precision injection parts, which are essential in industries requiring accuracy and reliability.

10. Hydraulic Unit

The hydraulic unit powers various movements within the injection molding machine, including the clamping unit, injection unit, and ejection system. It generates the required force and pressure to operate these components efficiently, using oil or specialized hydraulic fluids. The unit ensures smooth and precise movement of the mold and injection mechanisms, optimizing the machine's functionality by regulating the flow and pressure of the hydraulic fluid.

The hydraulic unit is crucial for ensuring the machine operates with the required force and precision. A malfunction or improper calibration can lead to inconsistent molding (inadequate clamping pressure or inaccurate injection), resulting in defective parts. A reliable hydraulic system is essential for achieving consistent, high-quality injection molded parts and improving the overall efficiency of the process. The hydraulic unit plays a key role in maintaining the precision and reliability necessary for industries that demand high-quality, high-precision components.

Why Is Understanding Injection Molding Machine Parts Important?

Understanding injection molding machine parts is critical because each component plays a crucial role in the efficiency, precision, and quality of the molding process. The successful operation of the machine relies on the proper functioning of these parts to transform raw plastic into high-quality molded components. A thorough understanding of the machine's components allows operators to optimize performance, troubleshoot issues, and effectively maintain the equipment, ensuring consistent part quality and minimizing downtime.

Knowledge of the components helps in making informed decisions about material selection, machine settings (temperature, pressure, and cycle times), and maintenance schedules. Malfunctions in key components (hopper, barrel, or clamping unit) tend to lead to significant disruptions in the production process, resulting in defects and reduced production efficiency. Proper understanding ensures accurate molding of parts that meet the required specifications and industry standards.

How Does an Injection Molding Machine Work?

An injection molding machine works by melting plastic material and injecting it into a mold cavity to form a desired shape. The process begins when plastic pellets or granules are fed into the hopper, from where they move into the barrel. The plastic is heated by the heaters and melted by the rotating screw in the barrel. The screw applies pressure to the molten plastic, pushing it towards the nozzle. The molten plastic is injected under high pressure into the mold cavity when the mold is closed, where it fills the space and takes the shape of the mold.

The mold opens, and the molded part is ejected using ejector pins once the plastic has cooled and solidified. The clamping unit ensures the mold remains securely closed throughout the process, while the hydraulic system powers the movements of various components, ensuring efficient operation. The process is repeated in cycles, allowing for the continuous production of high-precision injection molded parts. Understanding the system’s components helps optimize machine settings and ensure the production of high-quality injection parts with minimal defects.

Does Injection Molding Machine Design Affect Performance and Efficiency?

Yes, the design of an injection molding machine affects performance and efficiency. The machine's overall design ensures optimal coordination of components such as the hopper, barrel, screw, clamping unit, and hydraulic system. A well-designed system facilitates consistent material flow, accurate injection pressure, and precise temperature control, which are critical for high-quality, efficient production. For example, an optimized barrel and screw design ensures uniform material melting, while precise temperature regulation helps maintain consistent melt viscosity, preventing defects in the final part.

Poorly designed or improperly integrated components lead to several issues, including inconsistent material flow, poor cycle times, and higher energy consumption. Inefficient designs likely result in more frequent breakdowns and costly maintenance. Manufacturers enhance machine efficiency, reduce energy usage, extend equipment lifespan, and minimize downtime by improving the integration of these components. Careful attention to machine design ensures better part quality and contributes to a more cost-effective and reliable injection molding process.

When designing injection-molded parts, think beyond geometry. Draft angles, insert layout, and flow paths decide how easily the part releases, how the mold wears, and how long production stays efficient.Audrius Zidonis; Principal Engineer at Zidonis EngineeringNote from the Editor

What Are the Common Issues with Injection Mold Components?

Common Issues with Injection Mold Components are listed below.

- Plastic pellets become stuck or accumulate, leading to uneven material flow.

- Uneven temperature distribution results in incomplete melting or degradation of plastic material.

- A worn or damaged screw leads to poor material movement, inconsistent melting, or insufficient pressure during injection.

- The nozzle becomes clogged with plastic, causing poor flow into the mold cavity and defects in the molded parts.

- The mold experiences wear, leading to misalignment, flashing, or surface imperfections on injection molded parts.

- Insufficient clamping force or uneven pressure causes the mold to open during injection, leading to incomplete or deformed parts.

- Hydraulic leaks, pressure issues, or component failure result in loss of control over the injection, ejection, or clamping cycles.

- Broken or malfunctioning ejector pins cause difficulty in removing parts from the mold or can damage the molded parts.

- Inadequate or uneven cooling leads to warping, inconsistent part dimensions, or increased cycle times.

- Contamination of the plastic material results in defects, inconsistent coloration, or compromised part strength in the final injection parts.

How Can Injection Molding Issues be Prevented?

Injection molding issues can be prevented by ensuring proper machine setup, regular maintenance, and using the right materials. Following the manufacturer’s recommended machine settings for parameters (temperature, pressure, and cycle times) ensures the equipment operates optimally. Routine maintenance, including inspecting worn parts, cleaning the hopper, and checking the nozzle for blockages, prevents malfunctions and extends the machine's lifespan. Regular calibration of the clamping unit, screw, and barrel ensures precise control over material flow, pressure, and temperature, which is essential for quality production.

Using high-quality, contamination-free materials and proper storage techniques helps prevent material-related issues such as clogs, inconsistent flow, or degradation. Maintaining balanced mold cooling prevents warping and ensures uniform part dimensions. Regular inspection and replacement of worn mold components reduce defects and improve part consistency. Operator training and real-time monitoring of the molding process are essential for identifying and addressing potential issues early, ensuring consistent part quality, and reducing downtime.

Is Regular Maintenance Needed to Prevent Wear on Mold Components?

Yes, regular maintenance is needed to prevent wear on mold components. Mold parts (cavity, core, and ejector pins) are subjected to continuous friction, pressure, and thermal cycles during injection molding, which accelerates wear. Wear leads to misalignment, surface defects, and reduced precision, ultimately impacting the quality of molded parts without proper maintenance. Routine maintenance (cleaning, lubrication, and inspection of mold components) helps to ensure they maintain their performance and prevent damage. Maintenance reduces the risk of production downtime, lowers the likelihood of costly repairs, and extends the mold's lifespan, thus ensuring efficient and consistent operation by addressing wear early. Proper injection molding maintenance extends the lifespan of the mold, reducing the need for costly repairs or replacements, and ensuring the efficiency and consistency of the injection molding process.

How Do Sensors Optimize Injection Molding Machine Performance?

Sensors optimize injection molding machine performance by providing real-time data and feedback on various critical parameters (temperature, pressure, and flow rate). Temperature sensors ensure that the plastic reaches and maintains the correct melt temperature in the barrel, preventing overheating or underheating. Pressure sensors monitor injection force to maintain accurate filling, preventing defects from over- or under-injection. Flow sensors or flow meters track hydraulic oil flow or coolant flow rather than molten plastic movement inside the mold, helping maintain stable temperature and pressure conditions.

Sensors allow for immediate adjustments to optimize the molding process, reduce material waste, and prevent defects in molded parts by continuously collecting data. The data gathered is used for predictive maintenance, helping to identify potential machine issues before they lead to costly downtime or failure. Sensors improve the overall efficiency, consistency, and quality of injection molding, making the process more reliable and cost-effective.

Does Automation Improve Injection Molding Efficiency?

Yes, automation improves injection molding efficiency. Automation increases production speed and ensures consistent quality by reducing human error. Robotic arms, conveyor belts, and automated material handling systems streamline processes such as part removal, mold operation, and material flow, leading to faster cycle times and reduced downtime. Automated systems provide precise control over injection pressure, temperature, and cycle consistency, resulting in high-quality parts.

Integration with sensors and real-time monitoring systems allows for immediate adjustments, optimizing machine performance and reducing material waste. Automation enhances the injection molding process by boosting throughput, minimizing defects, and reducing labor costs, making the process more cost-effective and productive.

How Xometry Can Help

Xometry offers a full range of injection molding capabilities to help with your production needs. Request a quote today.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.